MS - SOUND decoders MS440 to MS990 and MN - NON-SOUND decoders MN170 to MN340 Page 51

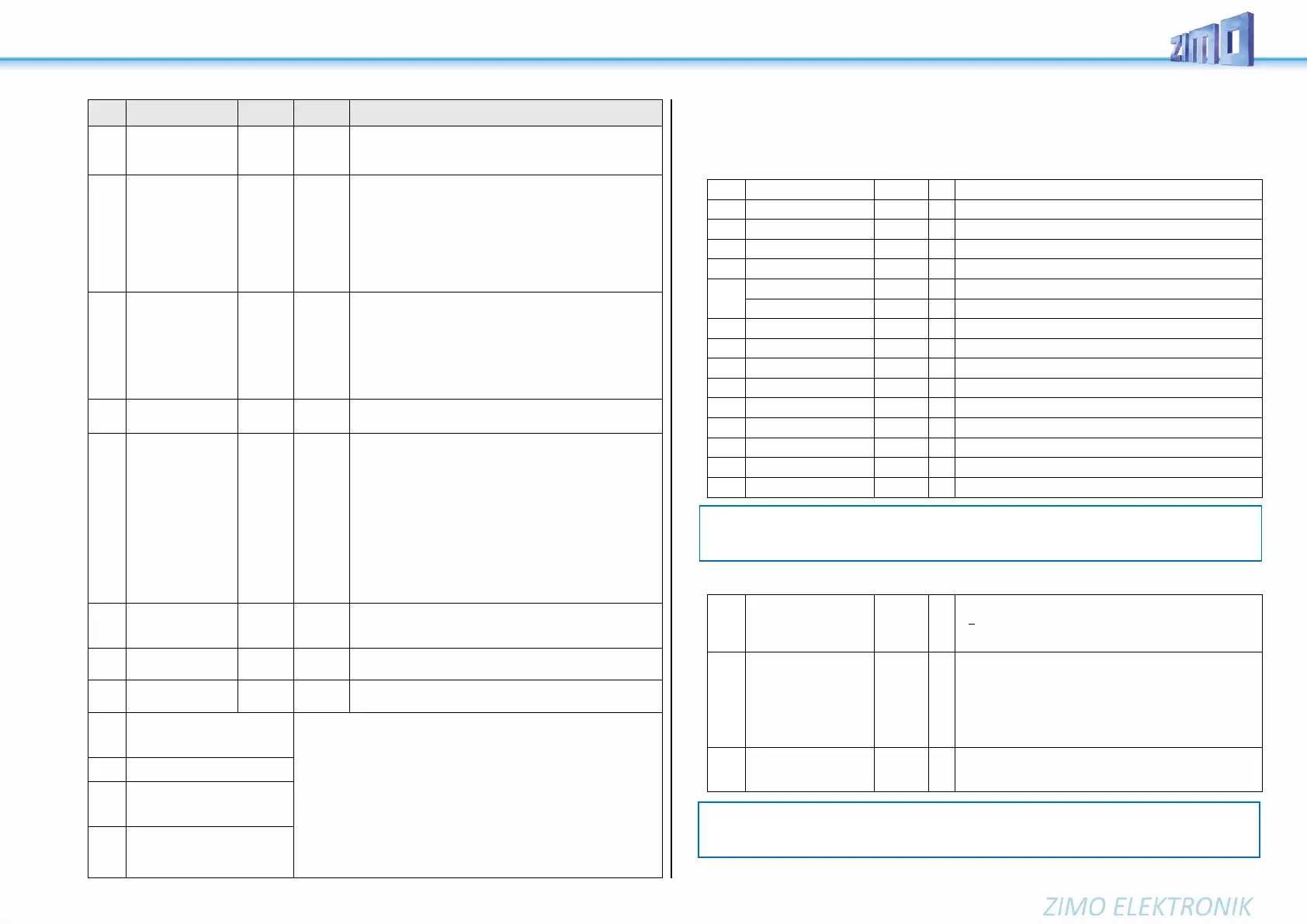

Threshold

for

brake squeal

The brake squeal should start when the speed drops below a

specific speed step. It will be automatically stopped at speed 0

(based on back-EMF results).

Brake squeal

Minimum drive time

The braking squeal is to be suppressed when an engine is

driven for a short time only, which is usually a shunting run and

often without any cars (it is mostly the cars that are squealing

not the loco itself!).

NOTE: Brake squeal sounds can also be assigned to a function

key (see allocation procedure CV #300 = …), with which the

brake squeal can be started or stopped manually! (SW version

5.00 and higher)

Cornering squeals

or

Reed configuration

Bit0 - switching input 1 activates cornering squeal

Bit1 - switching input 2 activates braking squeal

Bit2 - switching input 3 activates braking squeal

Bit3 - switching input 4 activates braking squeal

Bit7 - 0 = key defined in CV #308 suppresses cornering squeal

of Reed inputs if this key is ON

1 = key defined in CV #308 activates cornering squeal in-

dependent of Reed inputs

0: No key defined. Reed inputs always active.

1-28 = key F1 to F28.

Use of FO4

FO4 as normal

function output

or

FO4 as output for

steam exhaust fan

smoke generator in

steam locos

and

IN (reed) pins

Configuration

and

MS440: FO9 to pin IN4

= 0: FA4 used as normal function output,

i.e. controllable by a function key,

= 1: FA4 for smoke fan controlled by "simulated" axis detector

or by "real" axis detector. See CVs #267, #268!

NOTE: The operation mode of a fan is also determined by the

sound project.

NOTE: Large scale decoders have special outputs and setting

options for fans!

Bit 4 – inverts the polarity of Reed input 1

Bit 3 – inverts the polarity of Reed input 2

Bit 2 – inverts the polarity of Reed input 3

Bit 5 – inverts the polarity of Reed input 4

Bit 6 - (only types MS440) Pin IN4 becomes output FO9

Maximum volume for

volume increase key

Configuration range for volume with the help of the louder key

according to CV #397; can also be higher than the basic config-

uration in CV #266.

0 = No key defined.

1-28 = key F1 to F28 29 = F0-key

0 = No key defined.

1-28 = key F1 to F28 29 = F0-key

Conditions for switching be-

tween collections, as per

CV #345

Those CVs can be found in chapter

“Diesel and electro locos → ...”

.

They are valid for all types of drives,

but are mainly important for diesel locos.

Switch key

for driving and sound perfor-

mance when driving solo

Measures to be taken when

switching to solo drive (with key

selected in CV #347)

SW version 4.00 (sound projects for diesel and electro locos)

(not yet implemented in SW-version 4.00: Diesel with manual transmission)

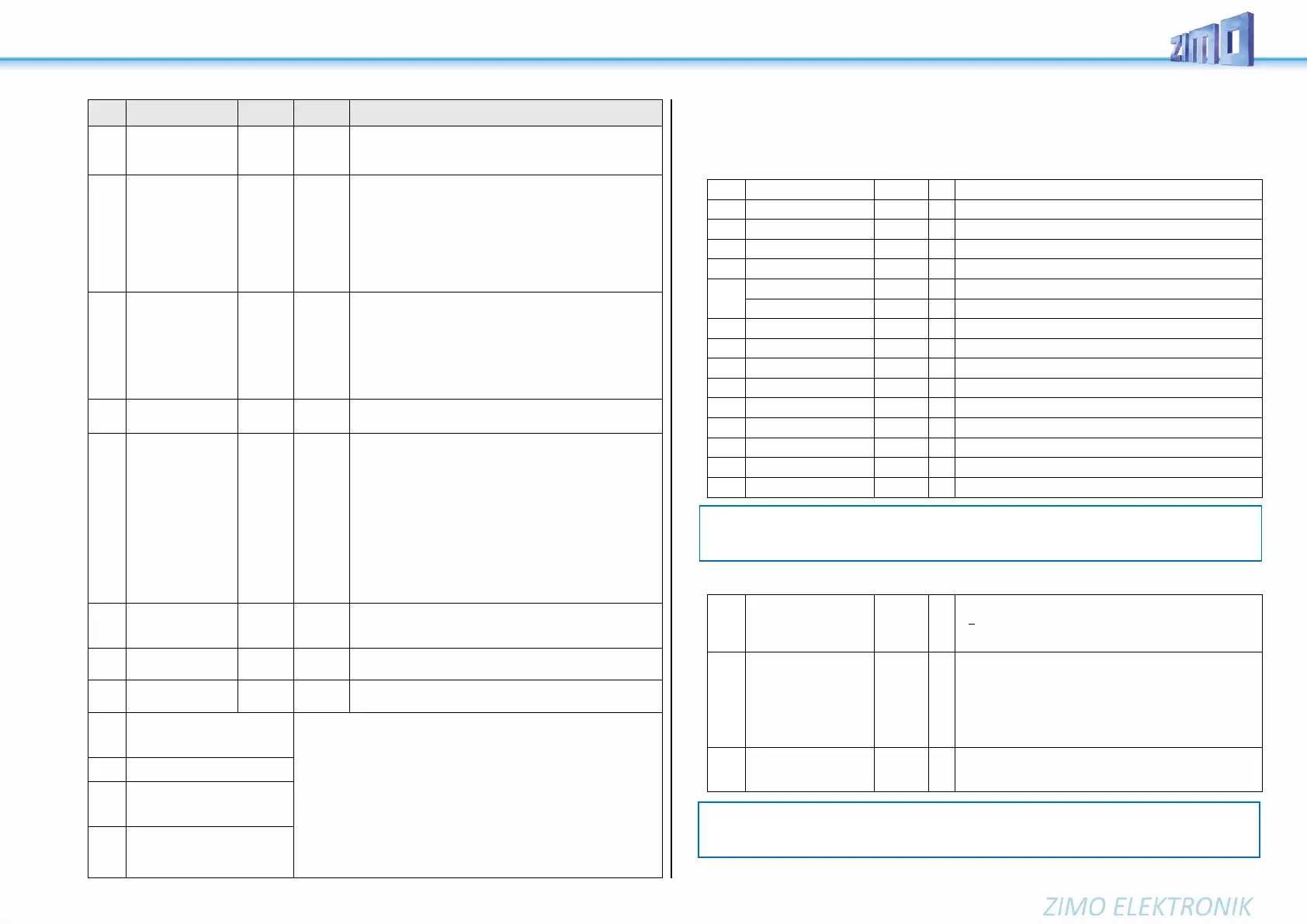

Background sounds - Volume adjustments:

Volume driving sound “simmering”

Sound “changing directions”

Volume driving sound for e.g. Johnson Bar

Thyristor sound volume (ELECTRIC engine)

Volume Starting whistle (STEAM/DIESEL)

Blow-off volume (STEAM engine)

Electric motor volume (ELECTRIC engine)

Planned for SW version 5.00

Electric switch gear sound

Switch gear volume (ELECTRIC engine)

Second thyristor (ELECTRIC)

Planned for SW version 5.00

Planned for SW version 5.00

Planned for SW version 5.00

Turbocharger volume (DIESEL engine)

Volume “cornering squeal”

Function sounds - Volume adjustments:

Sound volume operated with function key F0

= 0: full volume, original sound sample volume (same as 255)

= 1 - 254: reduced volume 1 – 99.5 %

= 255: full volume

#514

#517

#520

#523

…

#565

#568

Function sound F1

Function sound F2

Function sound F3

Function sound F4

…

Function sound F18

Function sound F19

Sound volume operated with function key F1

Sound volume operated with function key F2

Sound volume operated with function key F3

Sound volume operated with function key F4

…

Sound volume operated with function key F18

Sound volume operated with function key F19

Function sound F20

…

Function sound F28

Sound volume operated with function key F20

…

Sound volume operated with function key F28

NOTE: The CVs before the names (#573, #575, #577, etc.) contain information to the corresponding

sound sample (sound number, loop parameters), which can be modified, if necessary, usually by

the CV #300 procedure.

NOTE: The CVs between the above (#570, #572, #513, #515, #516, #518 etc.) contain information

to the corresponding sound samples (sample numbers, loop parameters etc.), which can also be

modified if needed, usually with the CV #300 procedures.

Loading...

Loading...