Page 42 Non-Sound Decoder MX618 - MX634 and Sound Decoder MX640 - MX648

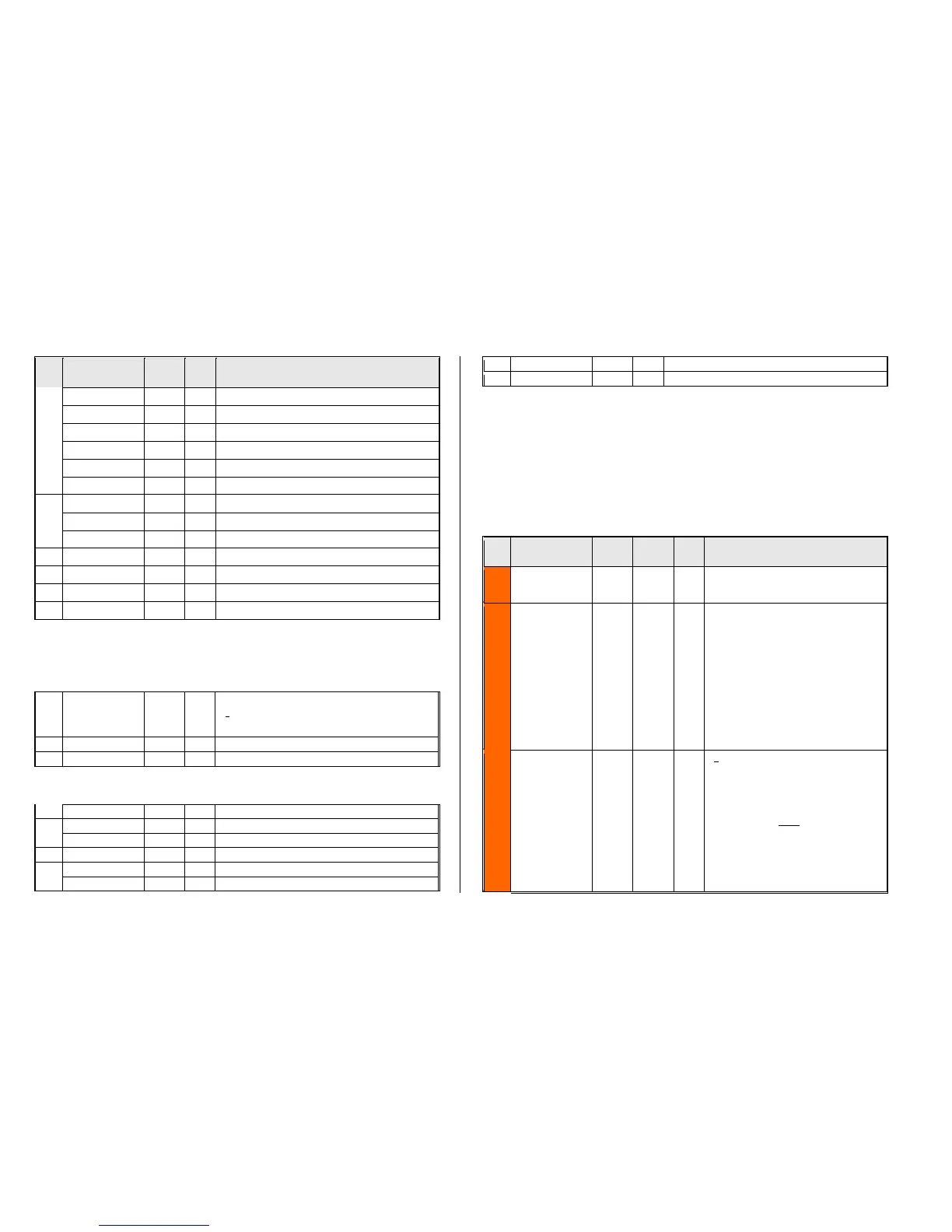

Volume for function sound F7

Volume for function sound F8

Volume for function sound F9

Volume for function sound F10

Volume for function sound F11

Volume for function sound F12

Volume for function sound F13

Volume for function sound F14

Volume for function sound F15

Volume for function sound F16

Volume for function sound F17

Volume for function sound F18

Volume for function sound F19

#674, #677…#698 = volume for sounds on F20, F21…F28.

Note: The CV’s between the above (#570, 572, #513, 515, 516, 518 etc.) hold information for the relevant sound

samples (sample numbers, loop parameters etc.), which can also be modified if needed, usually with the CV #300

procedures.

Switch input sounds - Volume adjustments:

Volume setting for the sound activated by switch input S1.

= 0: full volume, original sample volume (same as 255)

= 1 .. 254: reduced volume 1 - 99,5 %

= 255: full volume

Volume setting for the sound activated with switch input S2

Volume setting for the sound activated with switch input S3

Note: The CV immediately ahead of the CV’s listed (# 740, 742) contains the sound sample numbers to be played.

Random sounds - Volume adjustments:

Volume setting for sound activated by random generator Z1

Volume setting for sound activated by random generator Z2

Volume setting for sound activated by random generator Z3

Volume setting for sound activated by random generator Z4

Volume setting for sound activated by random generator Z5

Volume setting for sound activated by random generator Z6

Volume setting for sound activated by random generator Z7

Volume setting for sound activated by random generator Z8

Note: The CV immediately ahead of the CV’s listed (#744, 747 etc.) contain the sound sample numbers to be played.

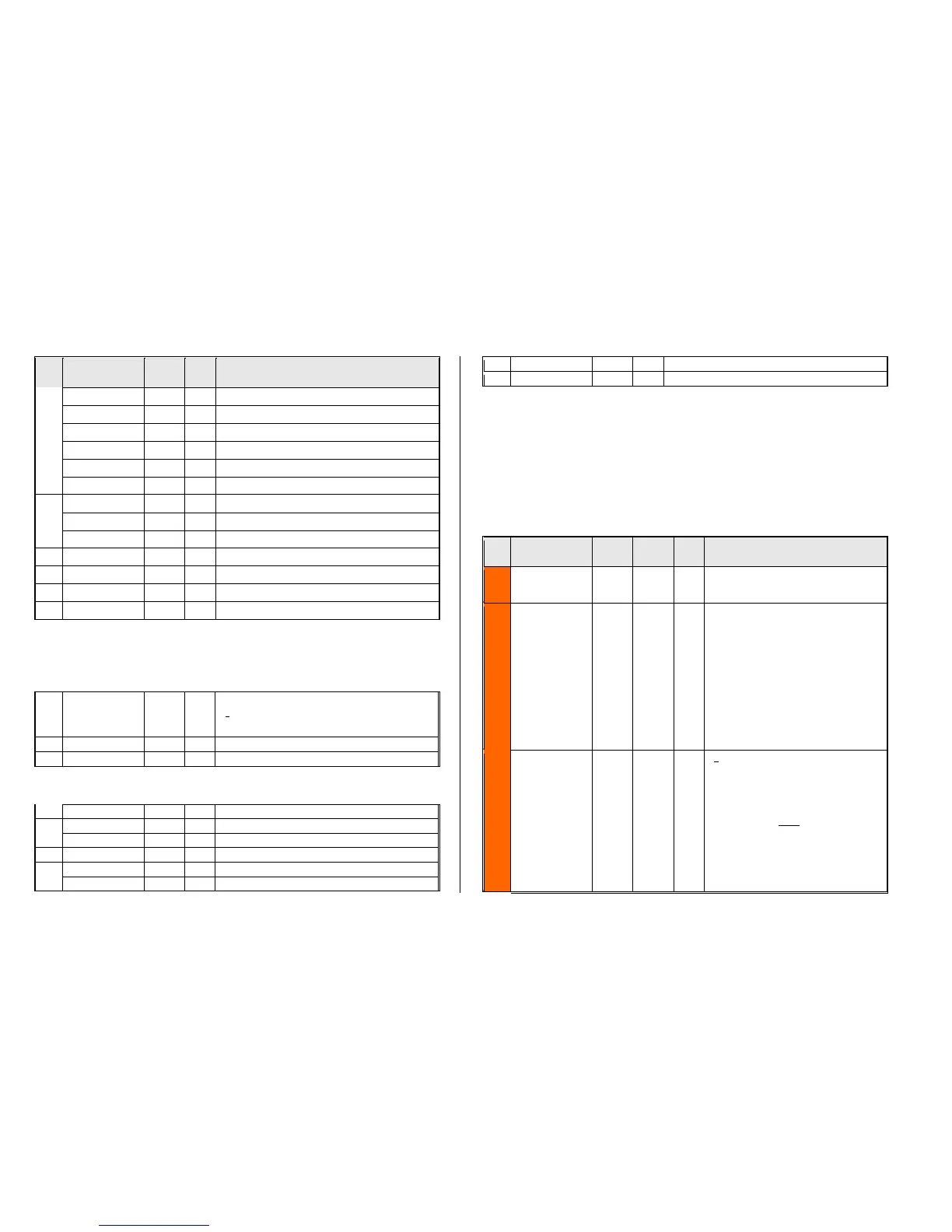

5.5 Steam engine

Basic sound settings

The following CV’s can be programmed both “normal” (i.e. CV #... = ...) and “incremental”. “In-

cremental programming” is especially useful when the proper value cannot be calculated in advance

and must be determined by trial, which is often the case with many sound parameters.

The “Lead CV” in each case is the first of a group of 3 CV’s, which are edited and displayed together

on a ZIMO MX31/MX32 cab during the “incremental programming” procedure.

See chapter

5.4 “Basic settings independent of powertrain”

Chuff sound

frequency with

“virtual cam sensor“

also see CV #354 in

this table

(chuff frequency at

speed step 1)

CV #267 is only active if CV #268 = 0:

Chuff beats follow the “virtual cam sensor”; an ac-

tual cam sensor is not needed in this case.

The default setting “70” results in about 4, 6 or 8

chuffs per wheel revolution, depending on the

chuff set selected; because it also depends in

large part on the motor and gearbox used, an in-

dividual adjustment is necessary in most cases in

order to achieve the exact chuff frequency. This is

the purpose for CV #267:

The lower the value the higher the chuff frequency

and vice versa. The setting should be performed

at a low speed (around speed step 10), but not at

the lowest speed step 1.

Switching to real

cam sensor

and

trigger count for chuff

rate

and

Special function for

“Simple articulated”

steam engines

= 0: “Virtual“ cam sensor is active (to be adjusted

with CV #267, see above).

= 1: real cam sensor is active (connected to

switch input 2 of the MX640, see chapter 6);

each negative spike results in a chuff beat.

= 2, 3, 4 … real cam sensor, several triggers in

sequence (2, 3, 4 …) result in one chuff beat.

= 128 (Bit 7=1 with “virtual” cam sensor): second

driver is a bit slower; only meaningful if a

second sound sample is available in the

sound project.

= 192 (Bit 6 and 7 = 1): When no separate sound

sample is available for the second driver, the

same sample is played back for the second

driver albeit a bit slower.

Loading...

Loading...