Large-scale Decoder & Sound Decoder MX695, MX696, MX697, MX699 Page 23

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

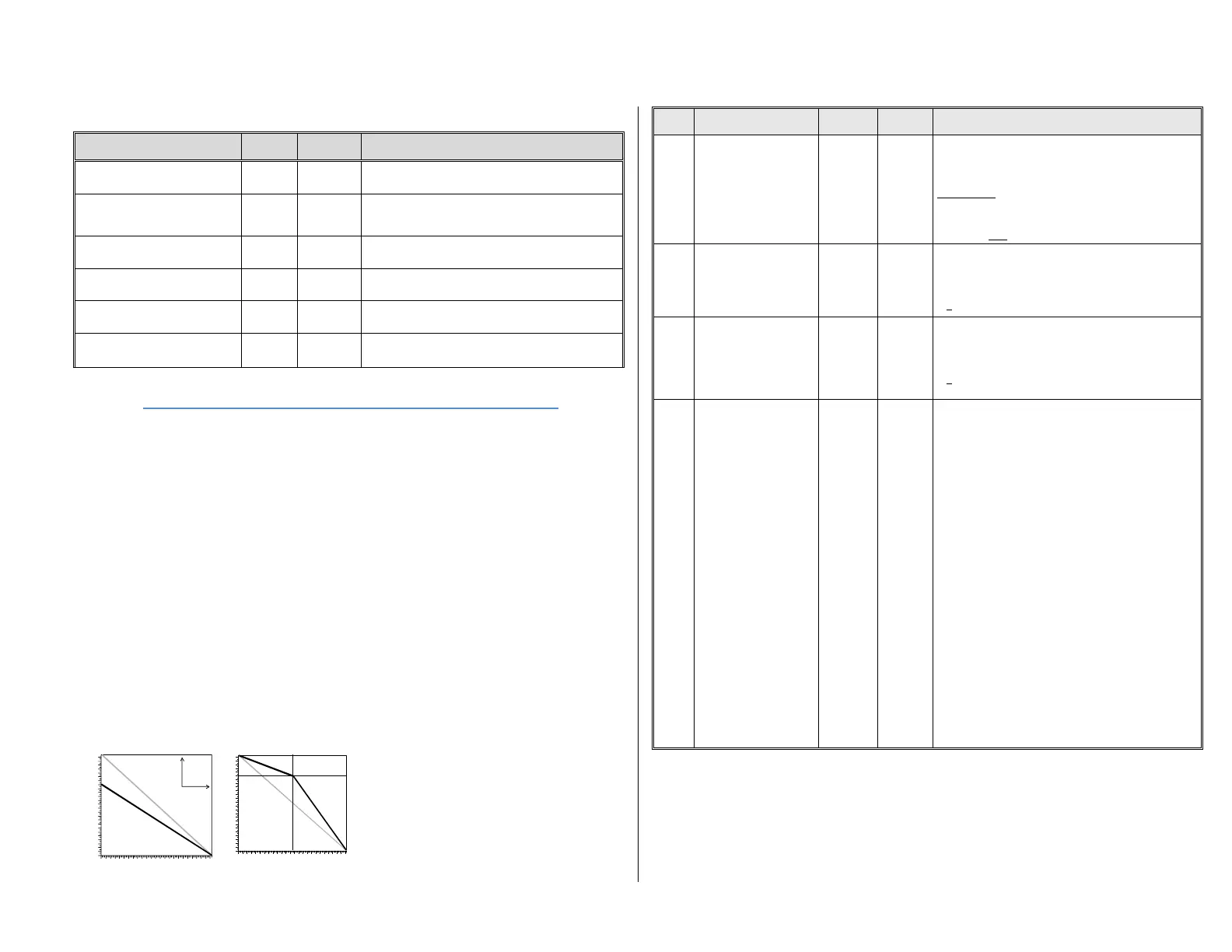

0 20 40 60 80 100 150 200 252

D

e

f

a

u

l

t

-

R

e

g

e

l

u

n

g

s

k

e

n

n

l

i

n

i

e

C

V

#

5

8

=

2

5

5

,

C

V

#

1

0

u

n

d

#

1

1

3

=

0

v

o

l

l

e

A

u

s

r

e

g

l

u

n

g

b

e

i

L

a

n

g

s

a

m

f

a

h

r

t

,

a

b

s

i

n

k

e

n

d

b

i

s

0

b

e

i

v

o

l

l

e

r

F

a

h

r

t

.

Regleungseinfluß

Int. Fahrstufe

K

e

n

n

l

i

n

i

e

d

e

s

R

e

g

e

l

u

n

g

s

e

i

n

f

l

u

s

s

e

s

C

V

#

5

8

=

1

8

0

,

C

V

#

1

0

u

n

d

#

1

1

3

=

0

r

e

d

u

z

i

e

r

t

e

A

u

s

r

e

g

l

u

n

g

i

n

a

l

l

e

n

G

e

s

c

h

w

i

n

d

i

g

k

e

i

t

s

b

e

r

e

i

c

h

e

n

.

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

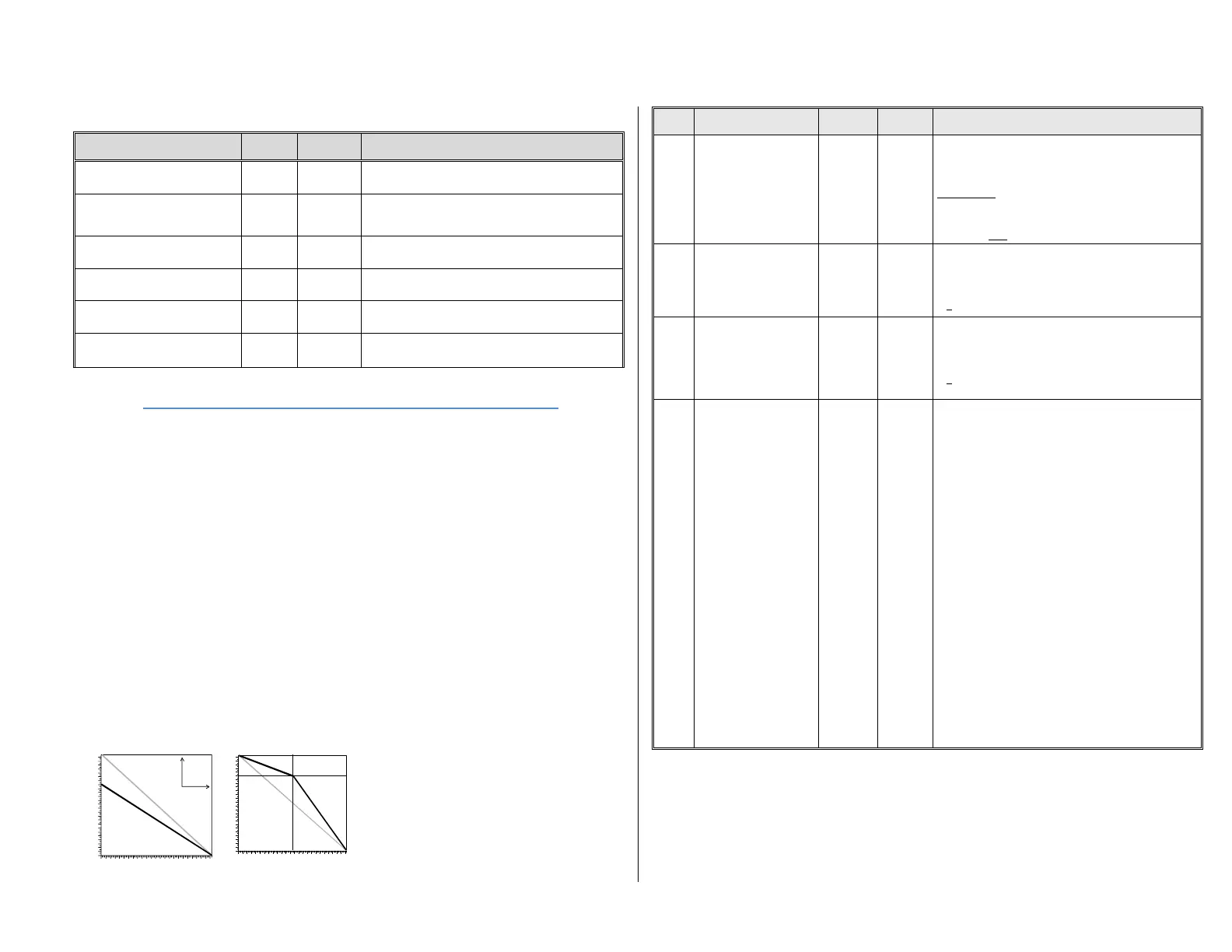

0 20 40 60 80 100 150 200 252

D

e

f

a

u

l

t

-

R

e

g

e

l

u

n

g

s

k

e

n

n

l

i

n

i

e

R

e

g

e

l

u

n

g

s

k

e

n

n

l

i

n

i

e

C

V

#

1

0

=

1

2

6

,

C

V

#

1

1

3

=

2

0

0

,

v

e

r

s

t

ä

r

k

t

e

A

u

s

r

e

g

l

u

n

g

i

m

m

i

t

t

l

e

r

e

n

G

e

s

c

h

w

i

n

-

d

i

g

k

e

i

t

s

b

e

r

e

i

c

h

.

Fine-tuning suggestions (if default settings are not satisfactory):

LGB-Loco with Bühler-motor(s)

The default settings are usually sufficient for good

vehicle performance.

Loco with Faulhaber motor

(Maxon)

Relatively rare and short EMF sampling times, “soft”

regulation, special Fauhaber procedure, quiet!

Märklin Gauge 1 (i.e. V100)

Slightly above average EMF sampling times, but al-

so “soft” regulation.

PIKO VT98 (light construction)

High sampling rate (but short EMF sampling times),

high P-value (but not I-value).

PIKO Taurus (relatively heavy)

Marginally higher sampling rate and P-value (be-

tween LGB and PIKO VT98).

Higher sampling rate, otherwise typical for Faulha-

ber.

Tips on how to proceed in finding the optimal CV #56 settings:

Start with an initial setting of CV #56 = 11; Run the engine at low speed while holding it back

with one hand. The motor regulation should compensate for the higher load within half a sec-

ond. If it takes longer than that, increase the ones digit gradually: CV #56 = 12, 13, 14...

With the locomotive still running at a low speed, increase the tens digit in CV #56 one step at the

time. For example: (if the test above resulted in CV #56 = 13) start increasing the tens digit CV

#56 = 23, 33 ,43…

As soon as jerky driving is detected, revert back to the previous digit this would be the final

setting.

Load Compensation, Compensation Curve and Experimental CV’s

The goal of load compensation, at least in theory, is to keep the speed constant in all circum-

stances (only limited by available power). In reality though, a certain reduction in compensation

is quite often preferred.

100% load compensation is useful within the low speed range to successfully prevent engine

stalls or run-away under light load. Load compensation should be reduced as speed increases,

so that at full speed the motor actually receives full power. Also, a slight grade-dependent

speed change is often considered more prototypical.

Locomotives operated in consists should never run at 100% load compensation in any part of

the speed range, because it causes the locomotives to fight each other and could even lead to

derailments.

The overall intensity of load compensation

can be defined with CV # 58 from no

compensation (value 0) to full compensa-

tion (value 255). Useful values range from

100 to 200.

For a more precise or more complete load

compensation over the full speed range

use CV #10 and CV #113 together with

CV #58 to define a 3-point curve.

Intensity of back-EMF for lowest speed step.

If required, an “intensity curve” can be defined for the

medium speed using CV #10, 58 and 113.

EXAMPLES:

CV # 58 = 0: no back-EMF

CV # 58 = 150: medium compensation

CV # 58 = 255: maximum compensation

EMF Feedback Cutoff

This CV is seldom used

Assigns an internal speed step where back EMF in-

tensity is reduced to the level defined in CV #113. CV

#10, #58 and #113 together define a back-EMF

curve.

= 0: default curve is valid (as in CV #58).

BEMF reduction

This CV is seldom used

The BEMF intensity is reduced to this value at the

speed step defined in CV #10.

CV #113 together with CV’s #58 and #10 form a 3-

point BEMF curve.

= 0: actual cutoff at speed step in CV #10. Usually

CV #10 is also set to 0.

Experimental CV’s

for test purposes,

to find out whether

certain automatic

settings have a nega-

tive effect on motor

regulation.

Using these

experimental CV’s will

deactivate the automat-

ic settings.

CV’s #147 – 149 will

likely be removed again

from the decoder SW at

some time.

--- CV #147 Sampling time ---

Useful initial value: 20;

Too small a value leads to jerky behavior.

Too large a value leads to poor low speed control.

0 = automatic control (CV #147 has no effect)

--- CV #148 D-Value ---

Useful initial value: 20;

Too small a value leads to poor regulation (regulates

too little, too slow, engine jerks (rather slowly).

Too large a value leads to over compensation, the

engine runs rough/vibrates.

0 = automatic control (CV #148 has no effect)

--- CV #149 P-Value ---

0 = automatic control (CV #149 has no effect)

1 = P-Value is fixed as per CV #56 (tens digit)

--- CV #150 Load compensation at top speed ---

Load compensation at top speed is normally always

0. This can be changed with CV #150.

Example: CV #58 = 200, CV #10 = 100, CV #113 =

80 und CV #150 = 40 --> Result: Regulation at

speed step 1 is 200 (of 255, almost 100%), at speed

step 100 it is 80 (@1/3

rd

of 255), at speed step 252

(full speed) it is 200 (of 255, almost fully regulated).

We kindly ask for your cooperation. Please send

us your test results!

Loading...

Loading...