9

© Copyright 2017 Zoeller

®

Co. All rights reserved.

STEP 6 Piping

1) Cut and dry-t the pipe and ttings as required for

1" (DN25) diameter discharge pipe (may be reduced

to 3/4" [DN20] diameter if codes permit).

2) While dry-tting the discharge pipe, position and

mark the location of the pump unit discharge tting.

3) Cut and dry-t 1-1/2" (DN40) vent pipe as required

to ensure that the vent pipe does not interfere with

other components. Make the connection to the pump

unit with the provided street elbow. A 2" x 1" (DN50

x DN25) 90° discharge tting and a 1-1/2" (DN40)

street elbow vent tting have been provided for space

constraints in a stand alone conguration. However,

these are not required for a built-in installation. It

will reduce Total Dynamic Head on the system and

simplify assembly on a built-in installation to utilize

straight pipe. For the discharge pipe, use a 2" (DN50)

straight coupling and reduce it down to 1" (DN25).

Proper venting is required for the toilet to ush.

Do not use a mechanical type vent.

4) Temporarily set the toilet in place to check that there

is no piping interference. Remove the toilet and set

it aside.

5) Clean, prime and solvent weld the discharge piping

and pump unit discharge tting.

When applying solvent weld to discharge tting,

ensure that none gets into the check valve assembly. Pay

close attention to the proper alignment of the discharge

tting previously marked above.

6) Clean and solvent weld vent piping as required for

proper venting.

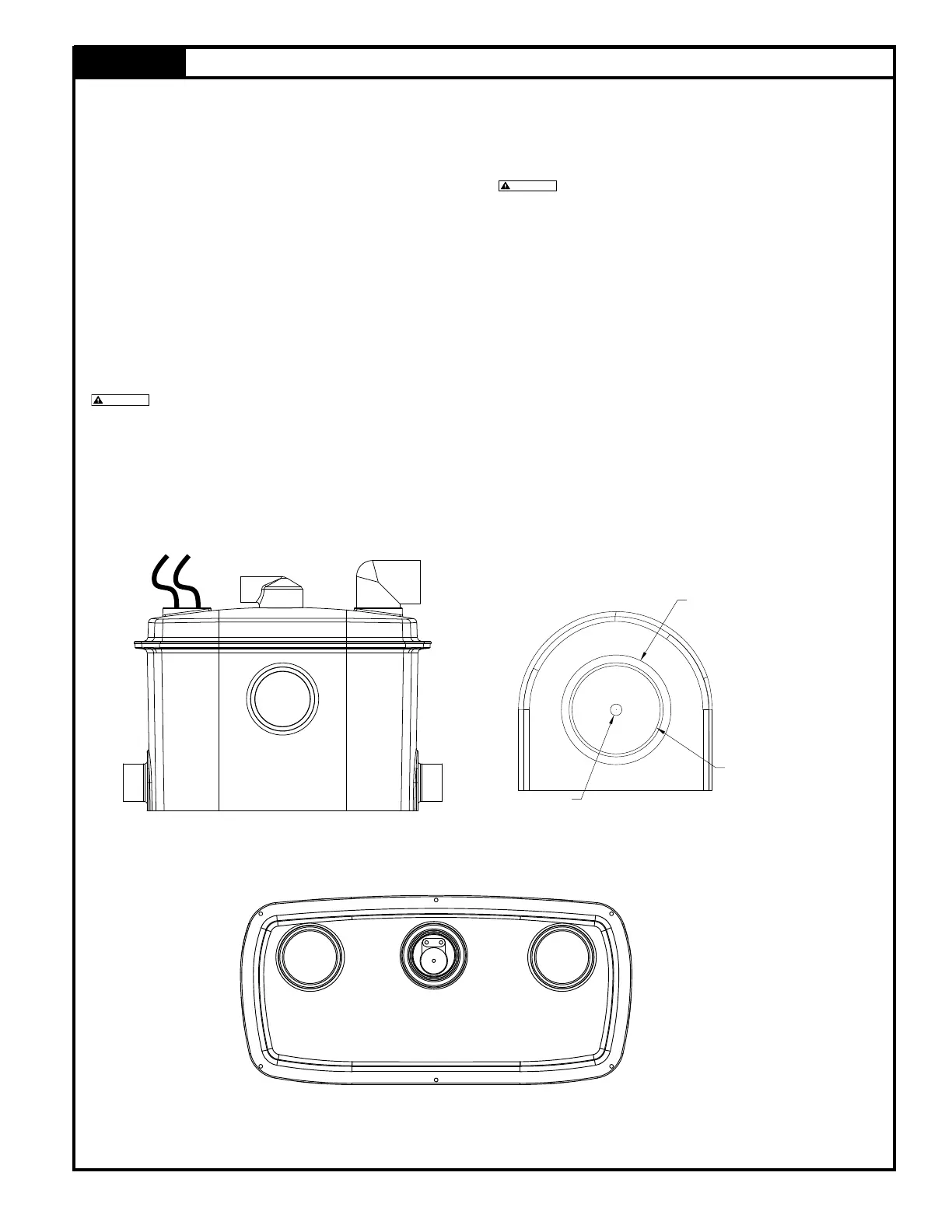

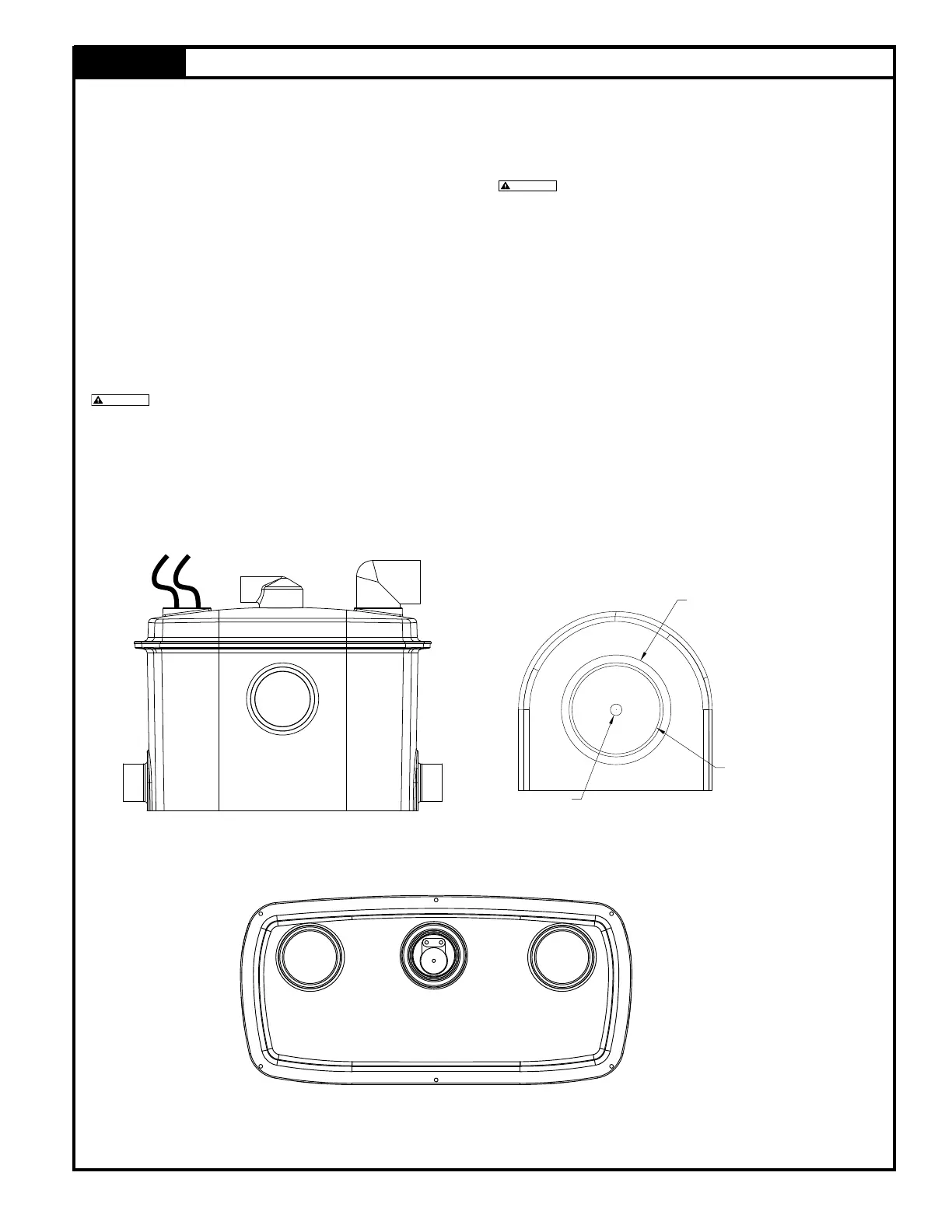

Note: Adding other bathroom xtures - The Qwik Jon

®

Ultima is designed to accept additional bathroom xtures

utilizing the two side inlets. These inlets can be attached

via the 2" MPT (outside diameter) or the 1-1/2" (DN40)

slip (inside diameter). These inlets must have the inner

portion drilled out using a 1-3/4" (44 mm) hole saw. This

is to ensure there is no leakage problems from inlets not

in use. When utilizing side inlets, install a check valve on

the incoming line.

SK2591

DRILL POINT

1-1/2" (DN40) SLIP INSIDE

2" MPT OUTSIDE

SK2586SK2589

Loading...

Loading...