Operation

©

3M 2006

5

Warm Up

Make certain that the 3M™ Scotch-Weld ™ Hot

Melt Applicator PG II is fully loaded with

adhesive. Set the off/on switch to the “on”

position, switch should light up, and set 3M

Scotch-Weld Hot Melt Applicator PG II in the

bench stand for 15 minutes. During this warm-up

period you may note a slight dripping from the

nozzle tip. This dripping is due to expansion of the

adhesive during warm-up.

Loading

After warm-up, load applicator with the 3M™

Scotch-Weld™ Hot Melt Adhesive you’ll be using on

the job. To do this, fully retract the Speedloader

piston by pulling one of the retract knobs located on

either side of the loading chamber. Insert up to three

3M Scotch-Weld Hot Melt Adhesive Sticks into the

chamber through the rear loading port. The applicator

is now ready for operation.

As adhesive is extruded, the piston will move

forward. This will be visually evident by the forward

movement of the retract knobs. As the piston

approaches the front of the chamber, a whistling

sound will be heard. At this point the piston may be

retracted and another adhesive stick will fall into

place. Applicator is again ready for operation.

Adhesive may be loaded into the chamber via the

rear port at any time during operation thus saving

time and increasing productivity.

If it is desired to remove adhesive once it is in the

loading chamber, simply roll the applicator to one

side and then point up. This will allow the adhesive

to roll up and out of the chamber.

In order to keep the Speedloader stick feed operating

at maximum efficiency, the chamber should be

sprayed inside while the piston is in the full forward

position with 3M™ Silicone Lubricant or equivalent

once a week.

CAUTION:

Never pull the trigger on the applicator unless there

is adhesive in the loading chamber.

Application

Get a feel for your new 3M Scotch-Weld Hot Melt

Applicator PG II. Start by applying small amounts of

adhesive in puddles on a piece of scrap or paper. Try

feathering the trigger. The 3M Scotch-Weld Hot Melt

Applicator PG II is unique in this respect. Pull the

trigger back slowly and note a small discharge of

adhesive; pull the trigger back more and note

increasing adhesive flow. When the trigger is fully

depressed; you will get maximum flow. If more or

less flow is desired, refer to page 17 of this manual.

Never operate the applicator without a nozzle tip.

Doing so could seriously damage the nozzle valve.

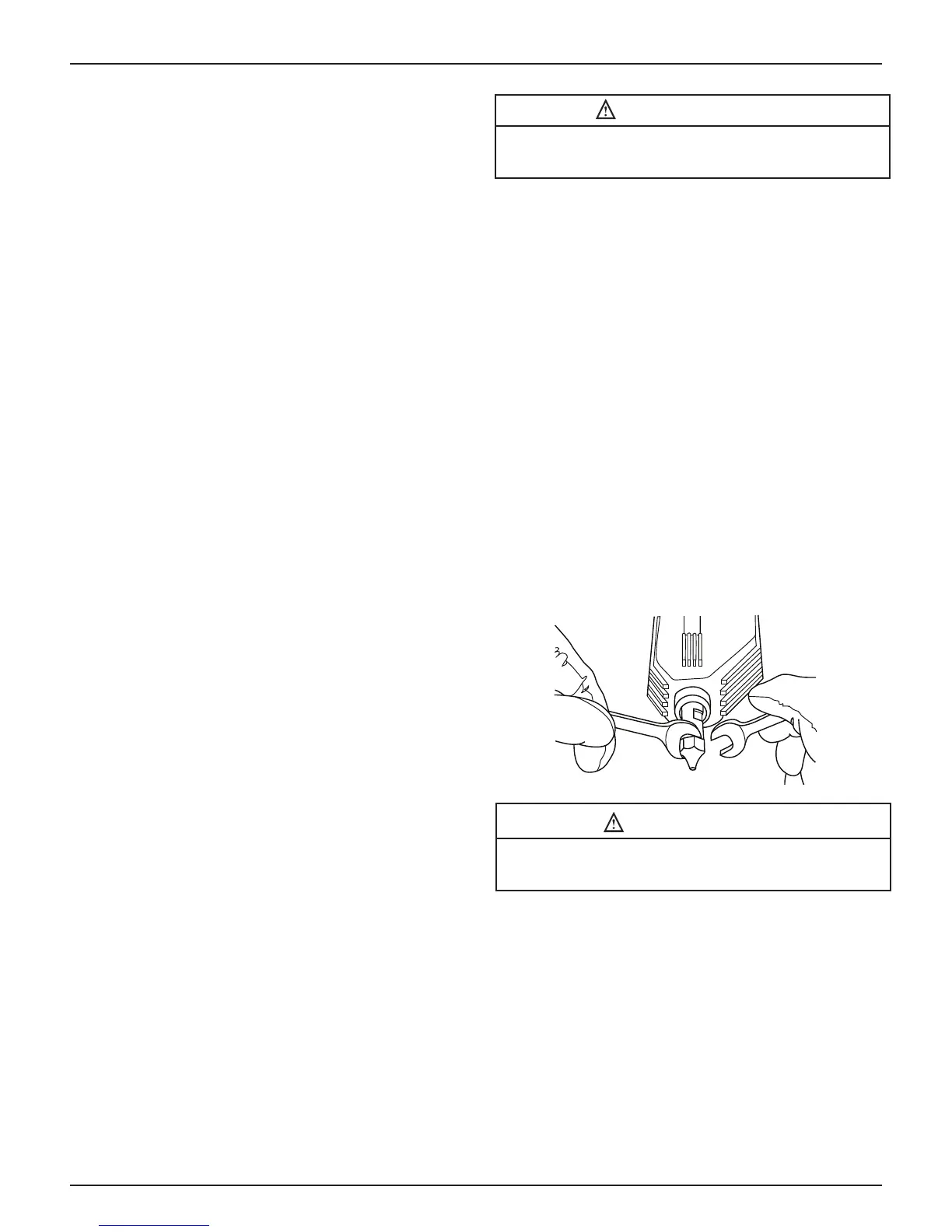

Changing Tips

The 3M Scotch-Weld Hot Melt Applicator PG II

includes two different tips as standard equipment.

Other tips, available from your Scotch-Weld Hot

Melt Adhesive distributor, are shown on page 17 of

this manual.

Caution:

Disconnect air and electrical power before servicing.

Wear heat resistant gloves while working on tips.

Tips can be changed only when the applicator is hot.

You will need a 5/8’’ and a 1/2’’ open-end wrench.

Hold the nozzle valve hex firmly with the 5/8’’

wench, while removing the nozzle tip with the 1/2’’

wrench. The accessory tip is mounted using the

reverse procedure. Snug the tip lightly.

Over

tightening could damage the valve assembly.

Loading...

Loading...