13

BURNER IGNITES (BRIEFLY)

• If the burner ignites briey then shuts off with an “Ignition Failure” error message, follow these steps:

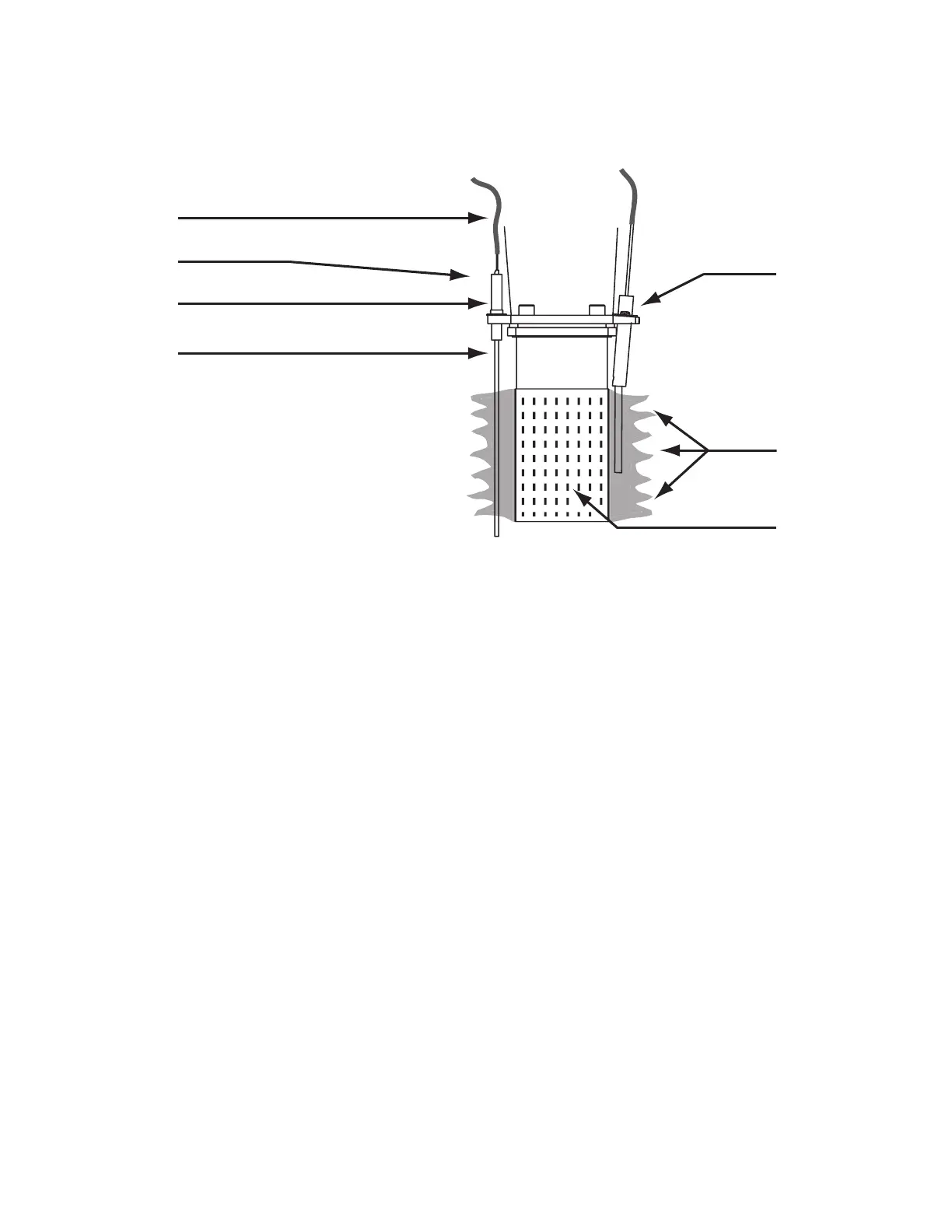

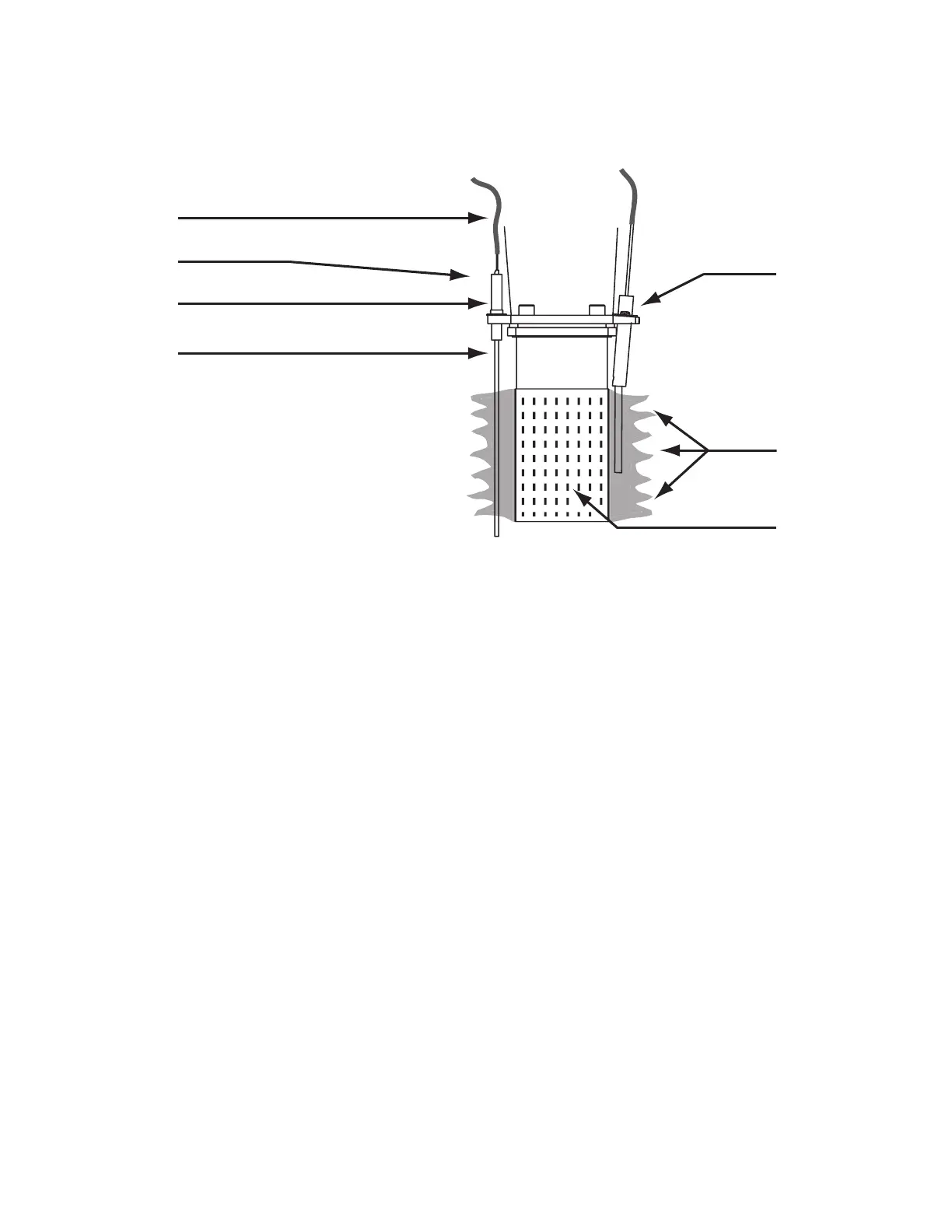

• Remove the connector from ame sense rod [picture of connector showing location on unit]. Inspect the connector for corrosion.

Replace if corroded or damaged. Remove Flame Sensor and clean metal end with steel wool.

• Check insulator for soot, cracks or other damage and replace if necessary.

SPARK

IGNITER

(MUST

CERAMIC INSULATOR

FLAME SENSOR

METAL CONDUCTOR

APPLIES AC CURRENT

TO FLAME SENSOR

C CURRENT FLOWS FROM THE FLAME

TO THE BURNER. THE BURNER

BE GROUNDED FOR CURRENT TO

. DURING THIS PROCESS THE AC

IS “RECTIFIED” AND BECOMES

DC CURRENT. DC MICRO AMP CURRENT

THE FLAME SENSOR

ND THE BURNER.

Figure 9. Checking the Burner

• Reinsert connector on Flame Sensor and make sure the electrical connection is clean and tight.

• Recycle unit again to start another ignition cycle. If the burner ignites but the ame sense rod still fails to detect ame, contact

Commercial Technical Support.

BURNER DOES NOT IGNITE

Failure to ignite (no ame) usually means a gas supply, gas-control valve, or sparking problem. If you do not see a brief blue ame

through the sight glass during the ignition cycle (at the moment the gas control valve icon appears on the display), follow these steps:

1. Install a gas pressure gage at the gas valve’s inlet pressure port, and conrm that the gas-supply pressure DOES fall, BUT falls no

more than 2”wc from static pressure when the gas valve is energized (you will hear a click sound when the gas valve is energized):

• If there’s no change in the gas pressure reading and/or the gas valve does not energized during the ignition, check the gas valve

wiring connections and the 24 Vac at the wire plug.

• If the supply pressure falls signicantly during the ignition, check the service-regulator capacity and gas-piping size to correct the

issue.

2. If you have conrmed Step 1 & Step 2, but NO ame is detected through the top-mounted combustion view-port, check the wiring

connections to the spark transformer and spark rod.

3. If you have conrmed Step 1 & Step 2, ame IS detected through the combustion view-port, BUT no ame icon is displays on the UIM,

check ame rod and ame rod wiring connections.

4. If you have conrmed Step 1 & Step 2, the ame icon is displays on the UIM momentarily or you experience occasional ignition

failures, adjust the gas valve throttle by turning it COUNTERCLOCKWISE 1/8 turn at a time.

If the gas valve setting resolves the ignition issue, you must use a combustion analyzer to verify the following:

a. That the combustion is clean.

b. The CO2 reading from the combustion ue is within 8.9% - 9.3% during heating cycle after the throttle adjustment.

Loading...

Loading...