30

Refrigerant Liquid Line Filter Driers:

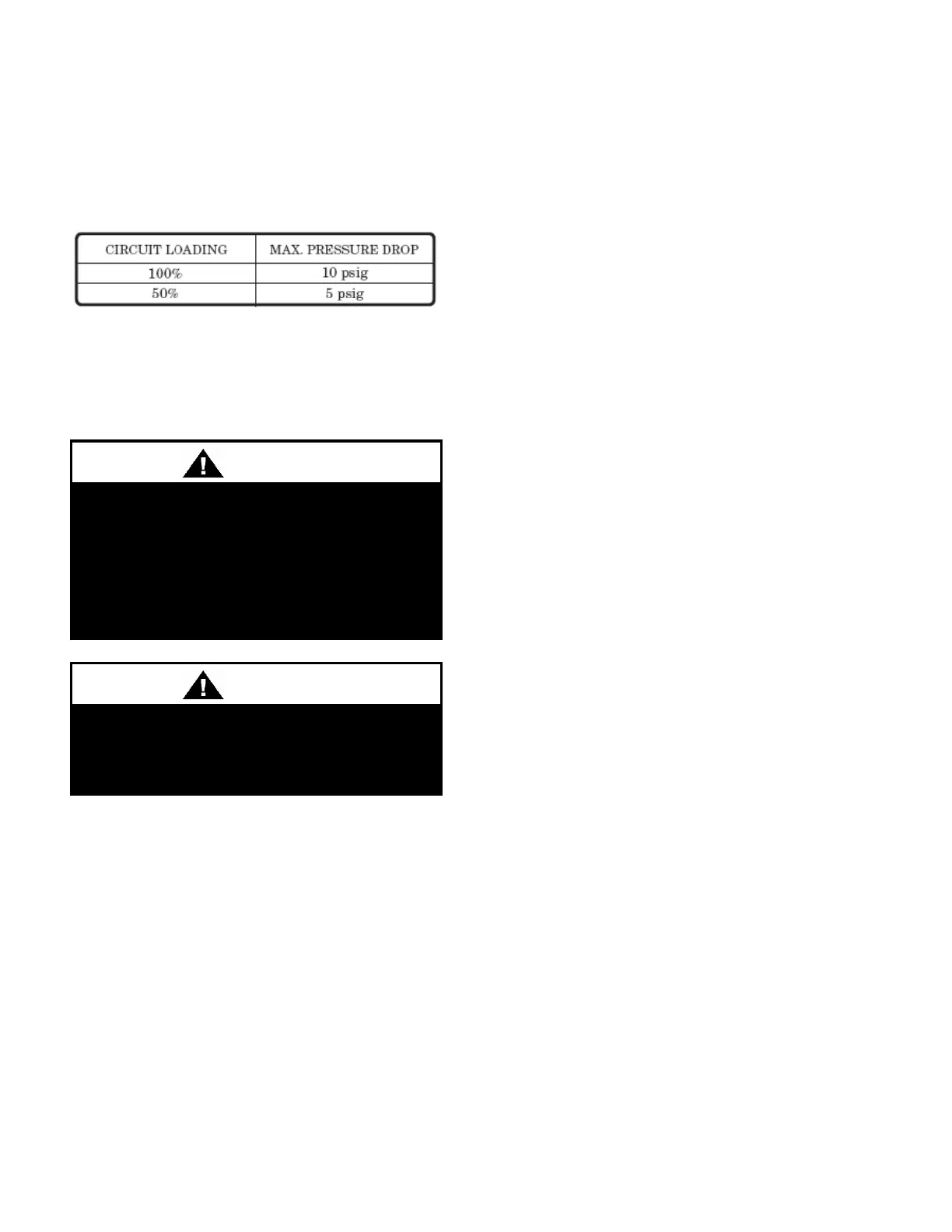

Each refrigerant circuit contains a replaceable

core filter drier. Replace when there is excessive

pressure drop across the assembly or moisture is

indicated in a liquid line sight glass.

Table 5 - Liquid Line Filter Drier Pressure Drop

The filter driers are provided with pressure taps

and shutoff valves for isolation when changing the

core. For safety purposes a service manifold must

be attached prior to filter maintenance.

Evaporator/Heat Exchangers:

Normally no maintenance or service work will be

required for a matching direct expansion

evaporator with a thermal expansion valve to

regulate refrigerant.

Lubrication:

All original motors and bearings are furnished

with an original factory charge of lubrication.

Certain applications require bearings be re-

lubricated periodically. The schedule will vary

depending on operating duty, temperature

changes, or severe atmospheric conditions.

Re-lubricate bearings at normal operating

temperatures, but not when running.

Rotate the fan shaft by hand and add only enough

grease to purge the seals. DO NOT

OVERLUBRICATE.

Service Information:

If the unit will not operate correctly and a service

company is required, only a company with service

technicians qualified and experienced in both

condensing units and air conditioning are

permitted to service the systems to keep

warranties in effect. If assistance is required, the

service technician must contact AAON.

Replacement Parts:

Parts for AAON equipment may be obtained from

your local AAON representative. When ordering

parts reference the unit serial number and part

number.

AAON Technical Support

2424 S. Yukon Ave.

Tulsa, OK 74107

Ph: (918) 382-6450

techsupport@AAON.com

www.AAON.com

Note: Before calling, technician must have model

and serial number of the unit available for the

service department to help answer questions

regarding the unit

Loading...

Loading...