21

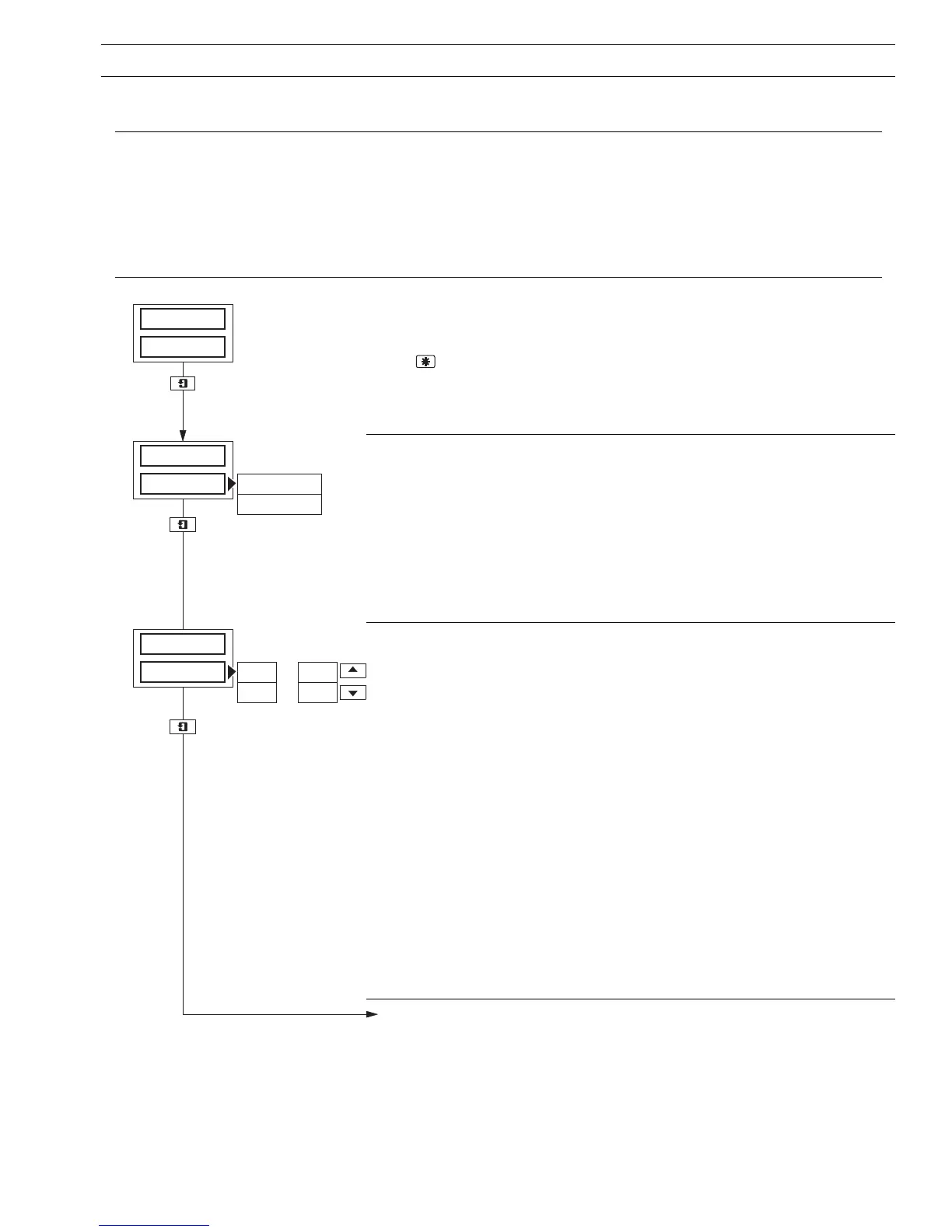

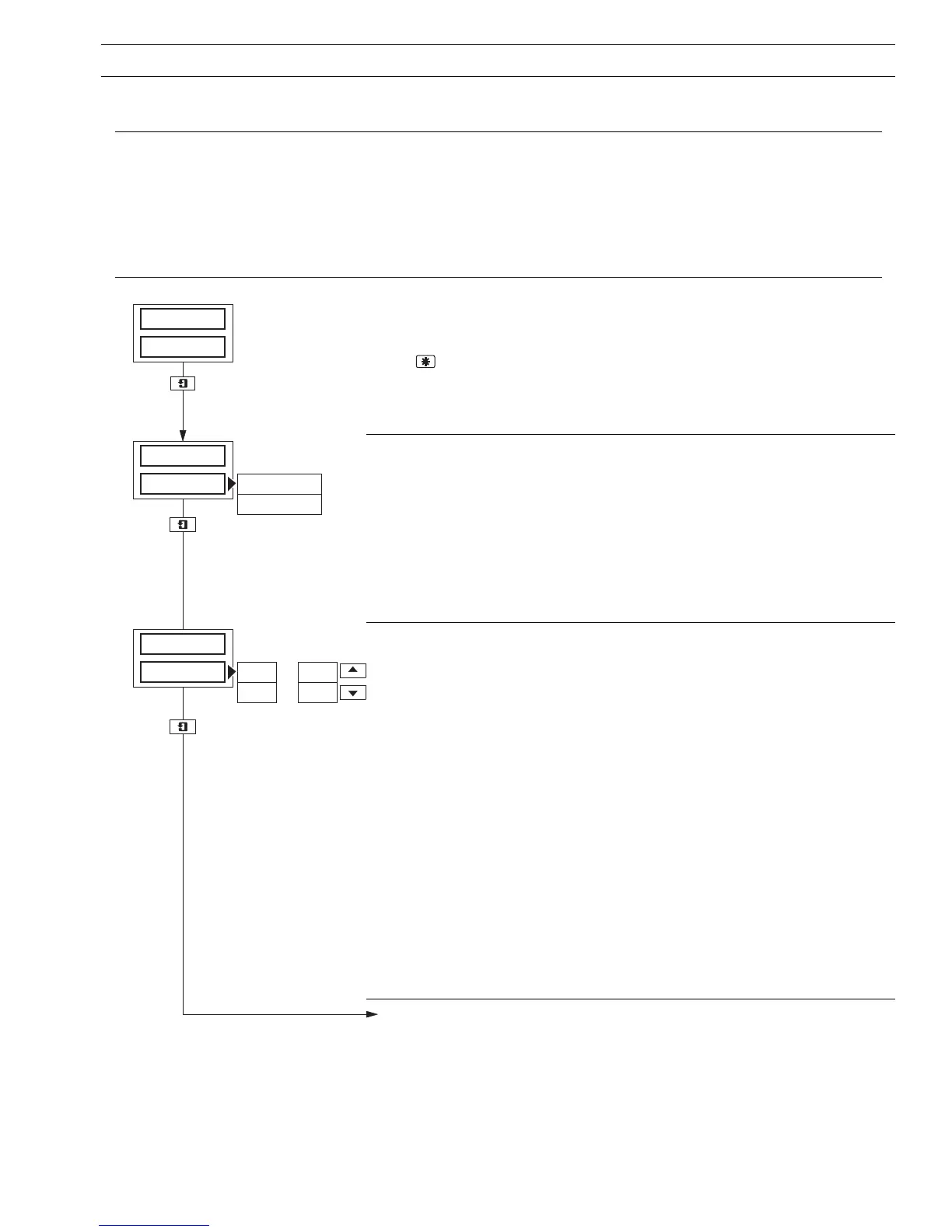

tUNE

At–tYP

AUtO

StrtUPStrtUP

At SPt

StEP

50

50

0

At

Set point

or

100

0

Start-up

5 CONTROL OPERATION…

Page Header – Auto-tune.

The

key can be programmed to jump to this frame (Set Up Function Keys Page,

ADVANCED CONFIGURATION LEVEL). If the key is used, the display reverts to the first

frame of the

Operating Page on leaving this Page.

Auto-tune Type

The two tuning facilities ('Start-up' and 'At Set point') are used to calculate

automatically the Proportional, Integral and Derivative terms required.

'Start-up' tuning is used from initial start-up or when there is a large change in set

point value.

'At Set point' tuning is used when the process is close to the required set point.

Select the auto-tune type required.

Output Step Size

The output step size is a percentage of the control output.

'Start-up' Tuning – the larger the step size used the quicker the auto-tuning process

is performed, but the greater the overshoot (above the calculated trip point). If too

small a step size is used the response may be too slow for the auto-tuning to operate

correctly. In practice, use as large a step size as can be tolerated.

'At Set Point' Tuning – the controller output changes by plus and minus the output

step size from its initial starting value when auto-tuning is executed. If the output step

size is too large to allow this its value is reduced,

Example – If the controller output value = 30% and the selected step size = 50%. The

step size is reduced to 30%.

The Step size should be large enough so that the amplitude of the process variable

excursions are at least four times larger than the hysteresis parameter to allow the

best possible response data. The output step size must be small enough to avoid

crossing either of the auto-tune limits (see following frames).

Set the step size required.

Continued on next page.

5.7.1 Auto-tuning Page

Information on Initial Conditions.

•'Start-up' Tuning – the controller is placed in the Manual control mode with the control output value set to give a stable

process variable at least 10% of the engineering range below the control set point.

• 'At Set Point' Tuning – may be initialized in the automatic mode but the process variable must be close to the required

set point and stable. The control output must also be stable. However, for best results the Manual control mode can be

used to stabilize the output and the process value. The output must be adjusted slowly to allow process response to the

change, to bring the process variable to the required control set point. The closer the process is to the set point, the more

effective the auto-tuning cycle.

Loading...

Loading...