Fläkt Woods 8265 GB 2011.10 7 Specifications are subject to alteration without notice

Installation and maintenance instruction

Fläkt Woods three phase asyncronous motor

Manufacturer: ABB

Theseinstructionsdonotcoveralldetailsorvariationsin

equipmentnorprovideforeverypossibleconditiontobe

metinconnectionwithinstallation,operationormain-

tenance.Shouldadditionalinformationrequired,please

contactthenearestABBSalesOffice.

Motor trouble shooting chart

Yourmotorserviceandanytroubleshootingmustbe

handledbyqualifiedpersonswithpropertoolsand

equipment.

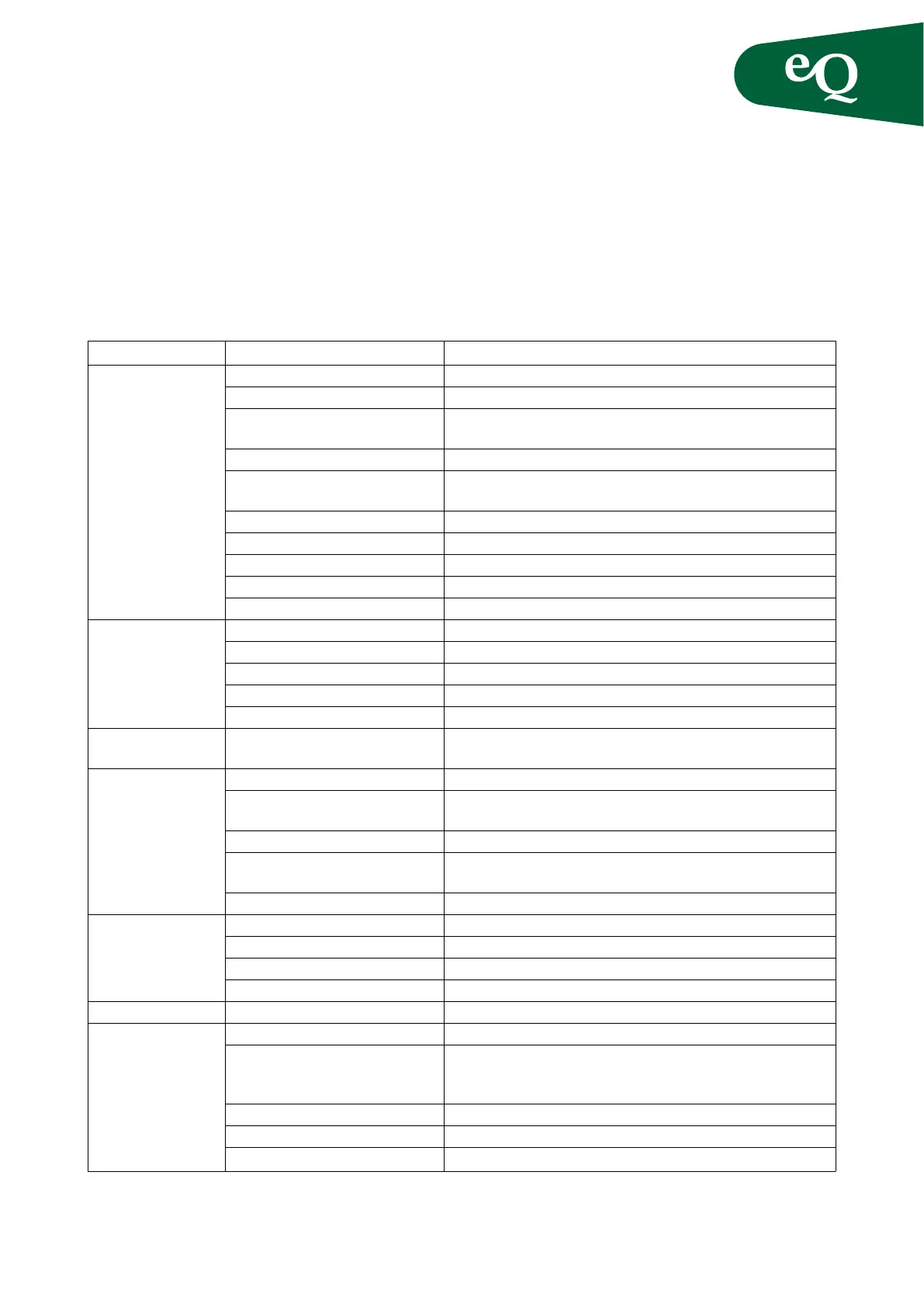

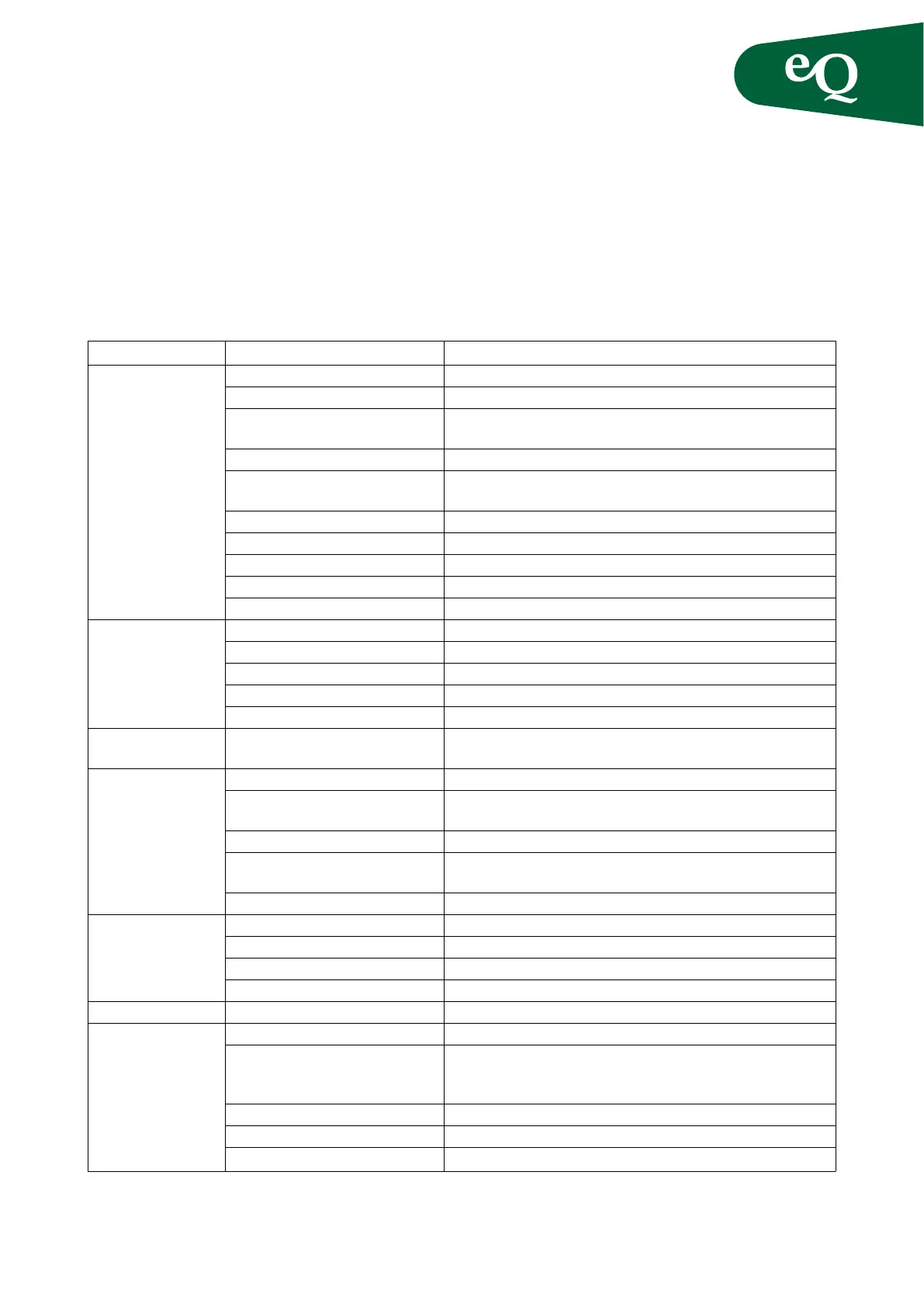

TROUBLE CAUSE WHAT TO DO

Motor fails to start Blown fuses Replace fuses with proper type and rating.

Overload trips Check and reset overload in starter.

Improper power supply Check to see that power supplied agrees with motor

name plate and load factor.

Improper line connections Check connections with diagram supplied with motor.

Open circuit in winding or control switch Indicated by humming sound when switch is closed. Check for loose

wiring connection. Also, ensure that all control contacts are closing.

Mechanical failure Check to see if motor and drive turn freely. Check bearings and lubrication.

Short circuited stator Indicated by blown fuses. Motor must be rewound.

Poor stator coil connection Remove end bells, locate with test lamp.

Rotor defective Look for broken bars or end rings.

Motor may be overloaded Reduce load.

Motor stalls One phase may be open Check lines for open phase.

Wrong application Change type or size. Consult manufacturer.

Overload Reduce load.

Low voltage Ensure the name plate voltage is maintained. Check connection.

Open circuit Fuses blown, check overload relay, stator and push buttons.

Motor runs and then

dies down

Power failure Check for loose connections to line, fuses and control.

Motor does not

come up to speed

Not applied properly Consult supplier for proper type.

Voltage too low at motor terminals

because of line drop

Use higher voltage or transformer terminals or reduce load.

Check connections. Check conductors for proper size.

Starting load too high Check load motor is supposes to carry at start.

Broken rotor bars or loose rotor Look for cracks near the rings. A new rotor may be

required, as repairs are usually temporary.

Open primary circuit Locate fault with testing device and repair.

Motor takes too long to

accelerate and/or draws

high amp

Excessive load Reduce load.

Low voltage during start Check for high resistance. Adequate wire size.

Defective squirrel cage rotor Replace with new rotor.

Applied voltage too low Get power company to increase power tap.

Wrong rotation Wrong sequence of phases Reverse connections at motor or at switchboard.

Motor overheats while

running underloaded

Overload Reduce load.

Frame or bracket vents may be clogged

with dirt and prevent proper ventilation

of motor

Open vent holes and check for a continuous stream of air from the motor.

Motor may have one phase open Check to make sure that all leads are well connected.

Grounded coil Locate and repair.

Unbalanced terminal voltage Check for faulty leads, connections and transformers.

Loading...

Loading...