For full instructions please follow the product manual which can be found on our web For full instructions please follow the product manual which can be found on our web

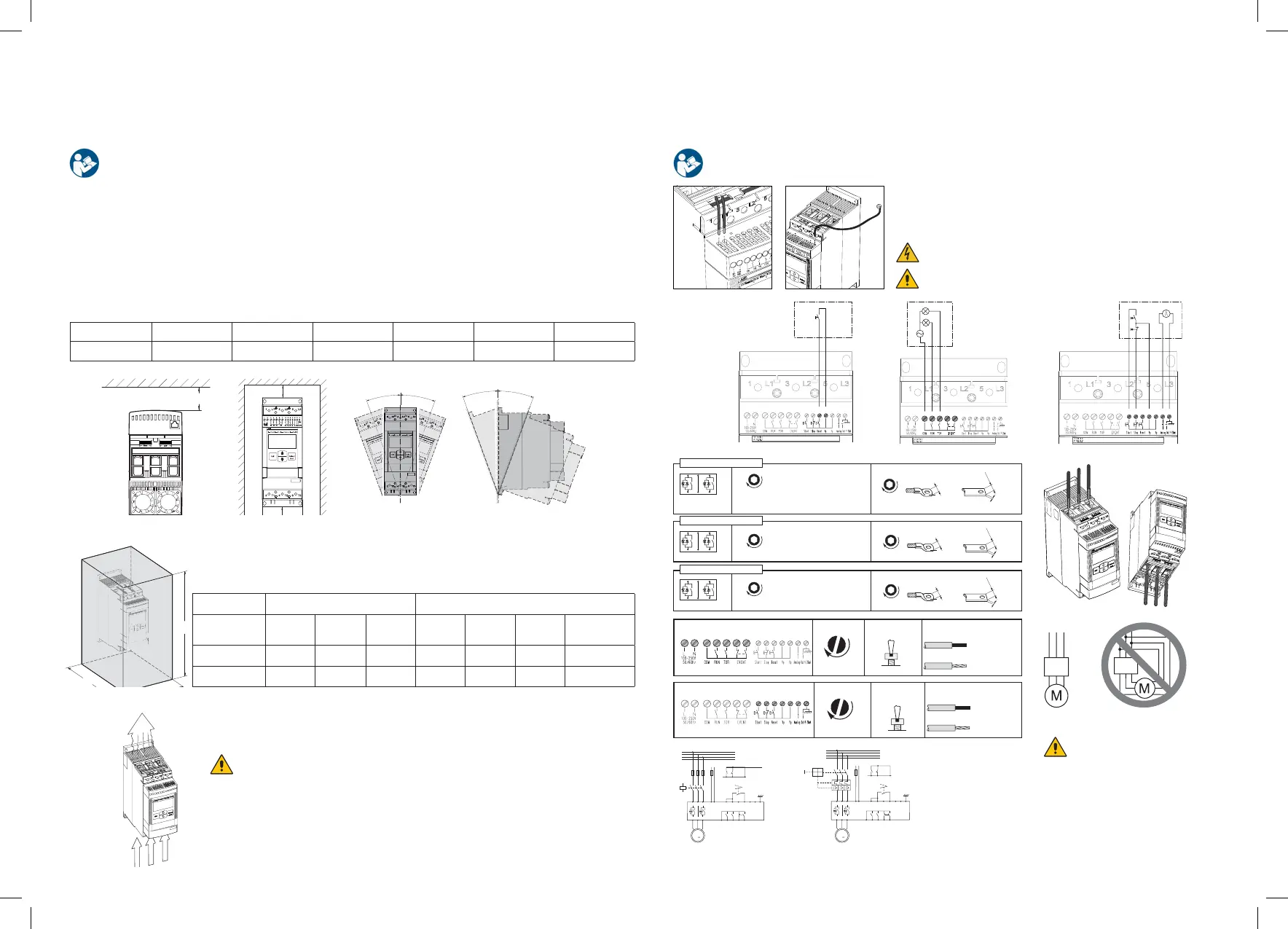

Hazardous voltage. Will cause death or serious injury. Turn off and lock out all power

supplying this device before starting work on this equipment.

To prevent an unintended direct start it's important to first power on the control supply

voltage. This will energize the bypass relays before mains are powered on to ensure the

relays are in open state.

Connecting Softstarters PSE18...PSE370 Inside

Delta will cause damage to the equipment, and

there is a risk of death or serious injury.

Ensure a free flow of air through the product.

Risk of damage to property. Ensure that no liquids, dust or conductive parts

enter the softstarter.

Using a too small enclosure and/or failure to follow the instructions in other

ways, may result in overheating of the PSE Softstarter and operational

disturbances.

—

Quick start guide

PSE18...370

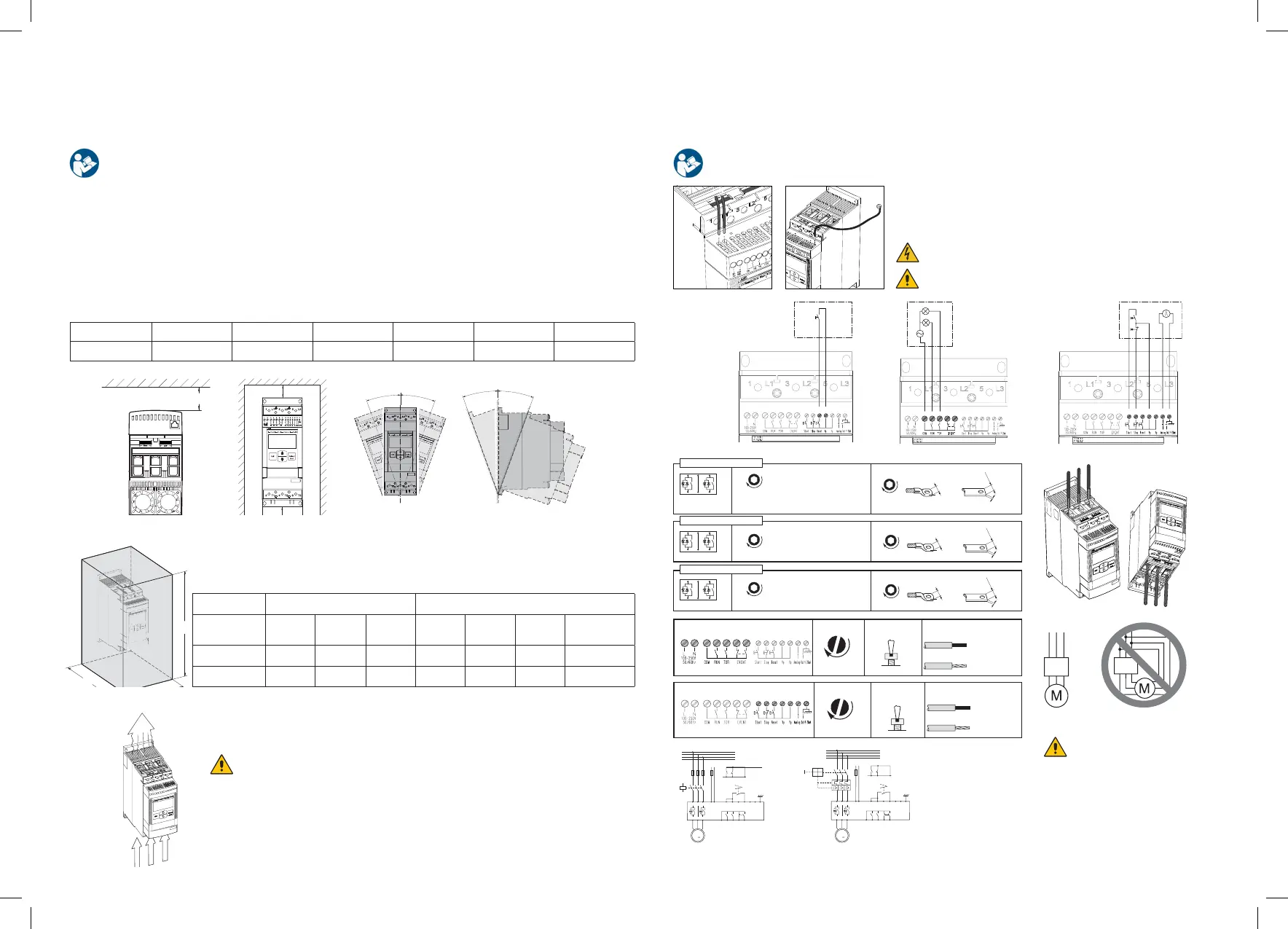

Mechanical installation

—

Quick start guide

PSE18...370

Electrical installation

Page 3/4Page 2/4

30

O

30

O

O

PSE 18-600-70

PSE 18-600-70

PSE 18-600-70

PSE 18-600-70

C

A

Mounting

The PSE Softstarters exist in three different physical sizes which are designed to be mounted with M6 bolts,

or bolts of equivalent dimension and strength. Verify the drilling plan on top of the box.

A (mm) B (mm) C (mm) A (in) B (in) C (in)

PSE18...370 20 10 100 0.787 0.394 3.937

8

4

5

6

7

9

10

11

12

13

14

PSE 18-600-70

81 2 3 4 5 6 7 9 10 11 12 13 14

Reset

PSE 18-600-70

81 2 3 4 65 7 9 10 11 12 13 14

AC

PSE 18-600-70

81 2 3 4 5 6 7 9 10 11 12 13 14

Start

Stop

Electrical installation

1. Connect the control supply voltage on terminals 1 and 2.

2. Connect the start/stop circuit and other I/Os.

3. Connect the mains on L1/L2/L3 and the motor to T1/T2/T3.

M8

1L1

2T1 4T2 6T3

3L2 5L3

max

22 mm

(0.866 in)

max

20 mm

(0.787 in)

max

5 mm

(0.197 in)

11/6-16 UNF-2A

275 lb.in

PSE142...170

1L1

2T1 4T2 6T3

3L2 5L3

3/4-16 UNF-2A

375 lb.in

PSE210...370

1L1

2T1 4T2 6T3

3L2 5L3

2,5 .. 10 mm

2

ATK185: AWG4 to 300kcmil

Al Cu 75°C only

2x2,5 .. 2x10 mm

2

AWG12 .. 6

6 Nm - 53 lb.in

8 Nm - 71 lb.in

10 .. 70 mm

2

2x10 .. 2x70 mm

2

AWG6 .. 2/0

M6

9 Nm - 80 lb.in

Using connection module

Using connection bars

max

30 mm

(1.181 in)

max

30 mm

(1.181 in)

max

10 mm

(0.394 in)

M10

28 Nm - 240 lb.in

Using connection bars

max

24 mm

(0.945 in)

max

22 mm

(0.866 in)

max

8 mm

(0.315 in)

M8

18 Nm - 160 lb.in

Using connection bars

Using connection module

Cu 75°C only

ATK300: AWG4 to 400kcmil

ATK300/2: AWG4 to 500kcmil or

2xAWG4 to 2x500kcmil

Al Cu 75°C only

Using connection module

Cu 75°C only

1 2 3 4 5 6 7

8 9 10 11

12 13 14

0,2 .. 4 mm

2

2x0,2 .. 1,5 mm

2

0,2 .. 4 mm

2

2x0,2 .. 1,5 mm

2

AWG 10 ... 24

0,5 Nm - 4,3 lb.in

4 x 0,8 mm

(0.157 x 0.031 in)

M3

1 2 3 4 5 6 7

8 9 10 11

12 13

0,2 .. 2,5 mm

2

2x0,2 .. 1,5 mm

2

0,2 .. 2,5 mm

2

2x0,2 .. 1,5 mm

2

AWG 12 ... 24

0,5 Nm - 4,3 lb.in

3,5 x 0,6 mm

(0.138 x 0.024 in)

M3

14

PSE

L1

L2

L3

N

KM1

1L1 3L2 5L3

2T1 4T2 6T3

6 7

NC NO

543

Run

TOR Fault

U

V

W

1 2 148 9

11

8 9

11

1210 13

M

3

Start Stop

Stop

Start

L N

L2

L3

N

MCCB

1L1 3L2 5L3

2T1 4T2 6T3

6 7

NC NO

543

Run

TOR Fault

U

V

W

1 2 148 9

11

8 9

11

1210 13

M

3

Start Stop

Stop

Start

L N

PSE

Circuit diagram PSE18-370

(Fuse and contactor version)

Circuit diagram PSE18-370

(MCCB version)

Inside Delta

IEC UL

H (mm) W (mm) D (mm) H (in) W (in) D (in) min number

of latches

PSE18...105 610 508 305 24 20 12 2

PSE142...370 762 610 305 30 24 12 4

Check that the distance to wall and front, as well as the mounting angle fulfills the requirements.

Mechanical installation

1. Follow the drilling instructions which can be found on the top part of the shipping box.

2. Make sure to have enough space according to our table below.

3. Install the product safely in place (may need two persons).

4. Make sure to mount the product in correct orientation according to the picture below.

In Line

In applications where the softstarter is installed in an enclosure, make sure that the

enclosure size is not smaller than the minimum recommended. Select size from the

applicable table for IEC or UL.

Loading...

Loading...