11. Event log

To collect sequence-of-events information, the re-

lay has a nonvolatile memory capable of storing

1024 events with the associated time stamps. The

non-volatile memory retains its data even if the re-

lay temporarily loses its auxiliary supply. The event

log facilitates detailed pre- and post-fault analyses

of feeder faults and disturbances. The considerable

capacity to process and store data and events in

the relay facilitates meeting the growing informa-

tion demand of future network configurations. The

sequence-of-events information can be accessed

either via local HMI or remotely via the communica-

tion interface of the relay. The information can also

be accessed locally or remotely using the Web HMI.

12. Recorded data

The relay has the capacity to store the records of

the 128 latest fault events. The records can be used

to analyze the power system events. Each record in-

cludes, for example, current, voltage and angle val-

ues and a time stamp. The fault recording can be

triggered by the start or the trip signal of a protec-

tion block, or by both. The available measurement

modes include DFT, RMS and peak-to-peak. Fault

records store relay measurement values at the mo-

ment when any protection function starts. In addi-

tion, the maximum demand current with time

stamp is separately recorded. The records are

stored in the non-volatile memory.

13. Condition monitoring

The condition monitoring functions of the relay

constantly monitor the performance and the condi-

tion of the circuit breaker. The monitoring com-

prises the spring charging time, SF6 gas pressure,

the travel time and the inactivity time of the circuit

breaker.

The monitoring functions provide operational cir-

cuit breaker history data, which can be used for

scheduling preventive circuit breaker maintenance.

In addition, the relay includes a runtime counter for

monitoring of how many hours a protected device

has been in operation thus enabling scheduling of

time-based preventive maintenance of the device.

14. Trip-circuit supervision

The trip-circuit supervision continuously monitors

the availability and operability of the trip circuit. It

provides open-circuit monitoring both when the

circuit breaker is in its closed and in its open posi-

tion. It also detects loss of circuit-breaker control

voltage.

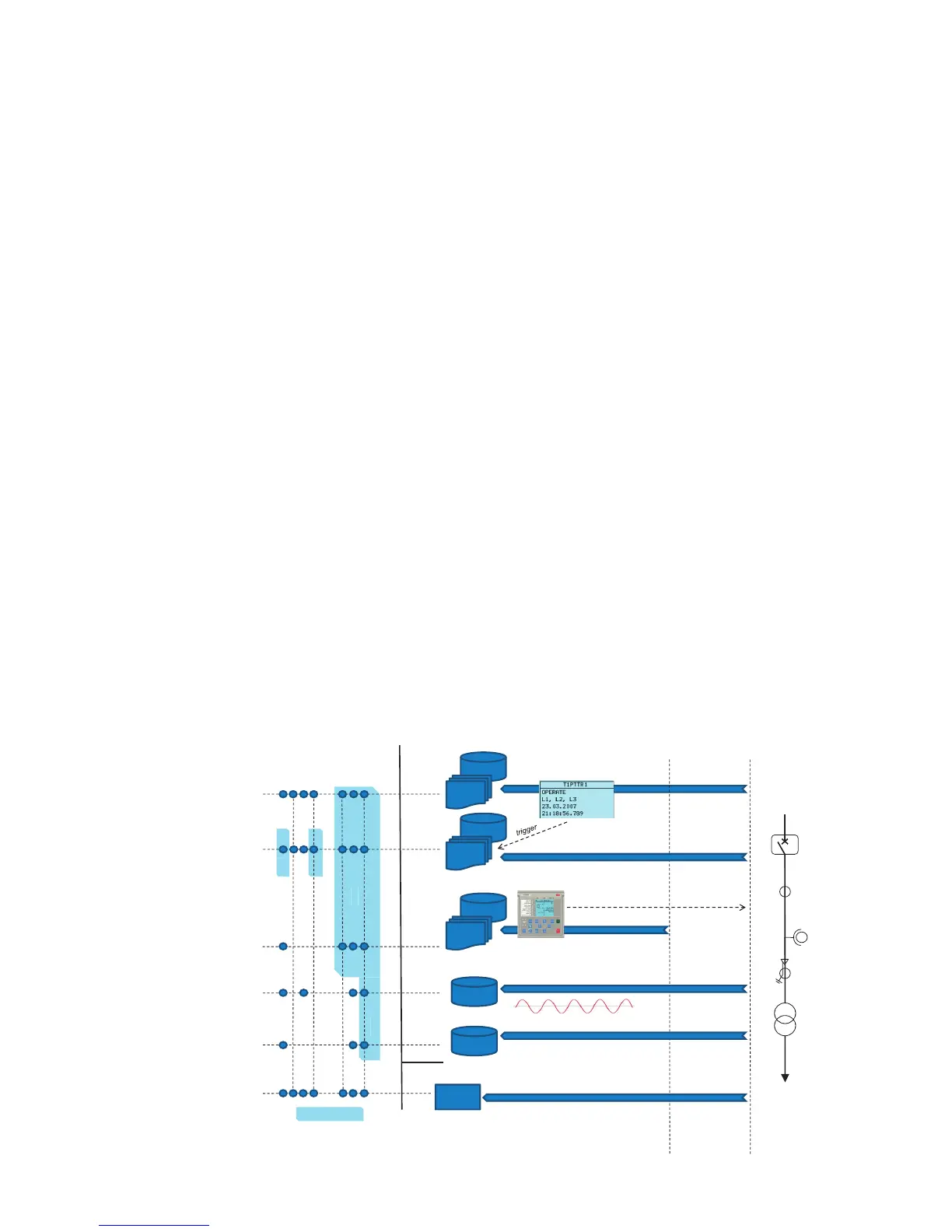

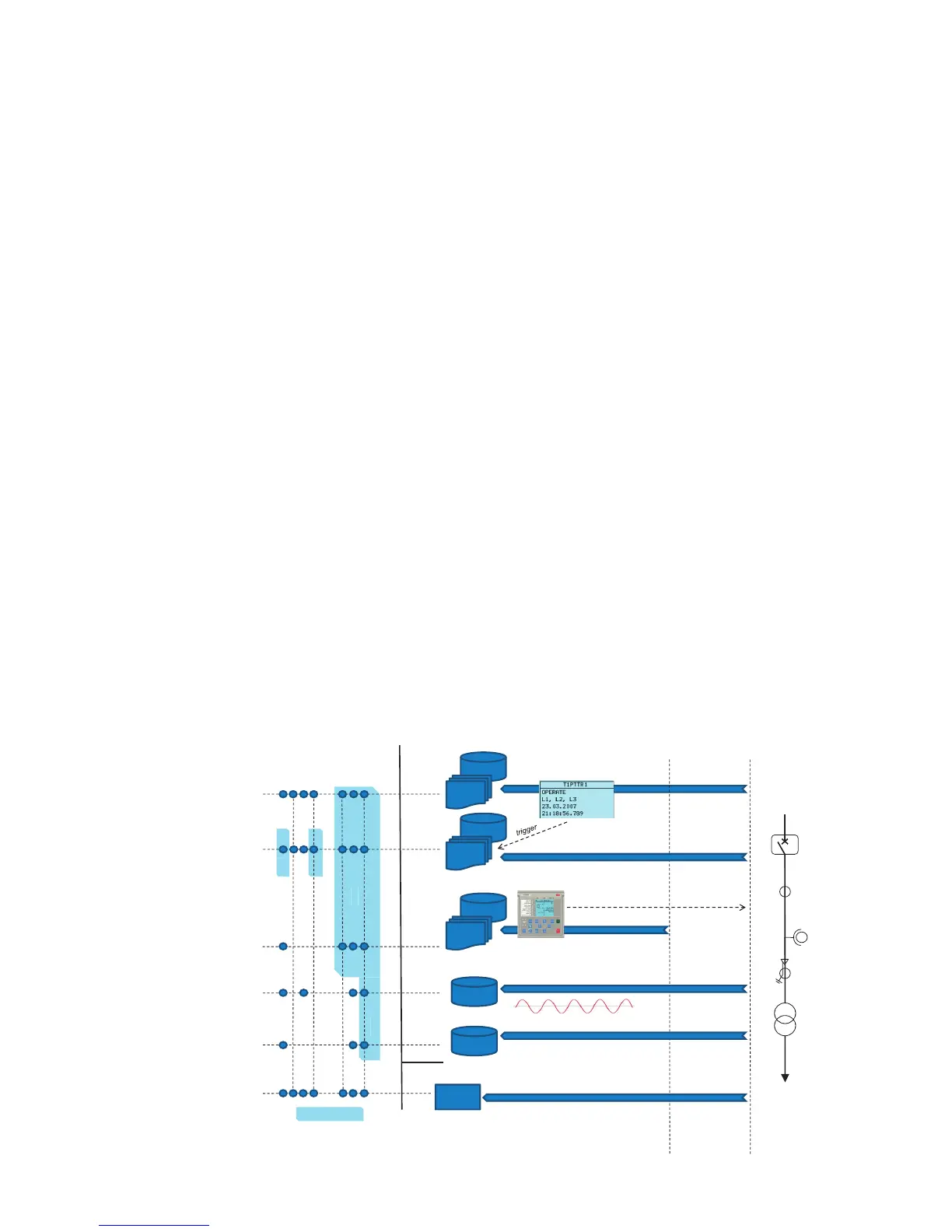

Figure 14. Recording

and event capabil-

ities overview

1024

PROCESS LEVEL

USER LEVEL

Fault summary;

Trip timestamp, Function, Currents, Voltages, etc.

BASIC FUNCTIONS

IEC 61850-8-1

Modbus

IEC 103

DNP3

LHMI

WHMI

PCM600

Process

events

(FIFO)

128

Fault

records

(FIFO)

System and security-related events;

Configuration changes, Control, Login, etc.

2048

Audit

trail

events

(FIFO)

n…100

Disturbance

records

...7 yrs

Load profile

record

Historical load data captured at a periodical

time interval (Demand interval 1 ...180min)

Function specific data

Min/max demand currents, Operation counters, etc.

History view

27

Loading...

Loading...