MEDIUM VOLTAGE PRODUCTS

25

Make sure that the circuit breaker is open

and the closing springs discharged before

removing the operating mechanism cover to

access the terminal box.

Table2

Bolt

Recommended tightening torque

(

)

Without lubricant With lubricant

(

)

(

1

)

The nominal tightening torque is based on a 0.14 friction coefficient of the

thread (distributed value to which the thread is subjected and which, in

some cases, is not negligible).

The nominal tightening torque with lubricant complies with DIN 43673

Standards.

(

2

)

Oil or grease. Thread and surfaces in contact with the lubricated heads.

Consider the deviations from the general Standards table (for example,

for systems in contact or terminals) as established in the specific

technical documentation.

The thread and surfaces in contact with the heads of bolts must be

slightly oiled or greased, so as to obtain a correct nominal tightening

torque.

Assembly procedures

Place the connections in contact with the circuit

breaker terminals.

Insert a spring washer and a flat washer

between the head of the bolt and the

connection.

The diameter of the flat washers must be able to

distribute the torquing pressure over a wide

area.

Tighten the bolt, taking care to prevent the

insulating parts from being stressed. Use of DIN

class 8.8 standard bolts is recommended, also

with reference to the indications in table 2.

Make sure that the connections do not exert any

force on the terminals.

Carefully comply with the manufacturer’s

instructions for terminating the cables in cable

connections.

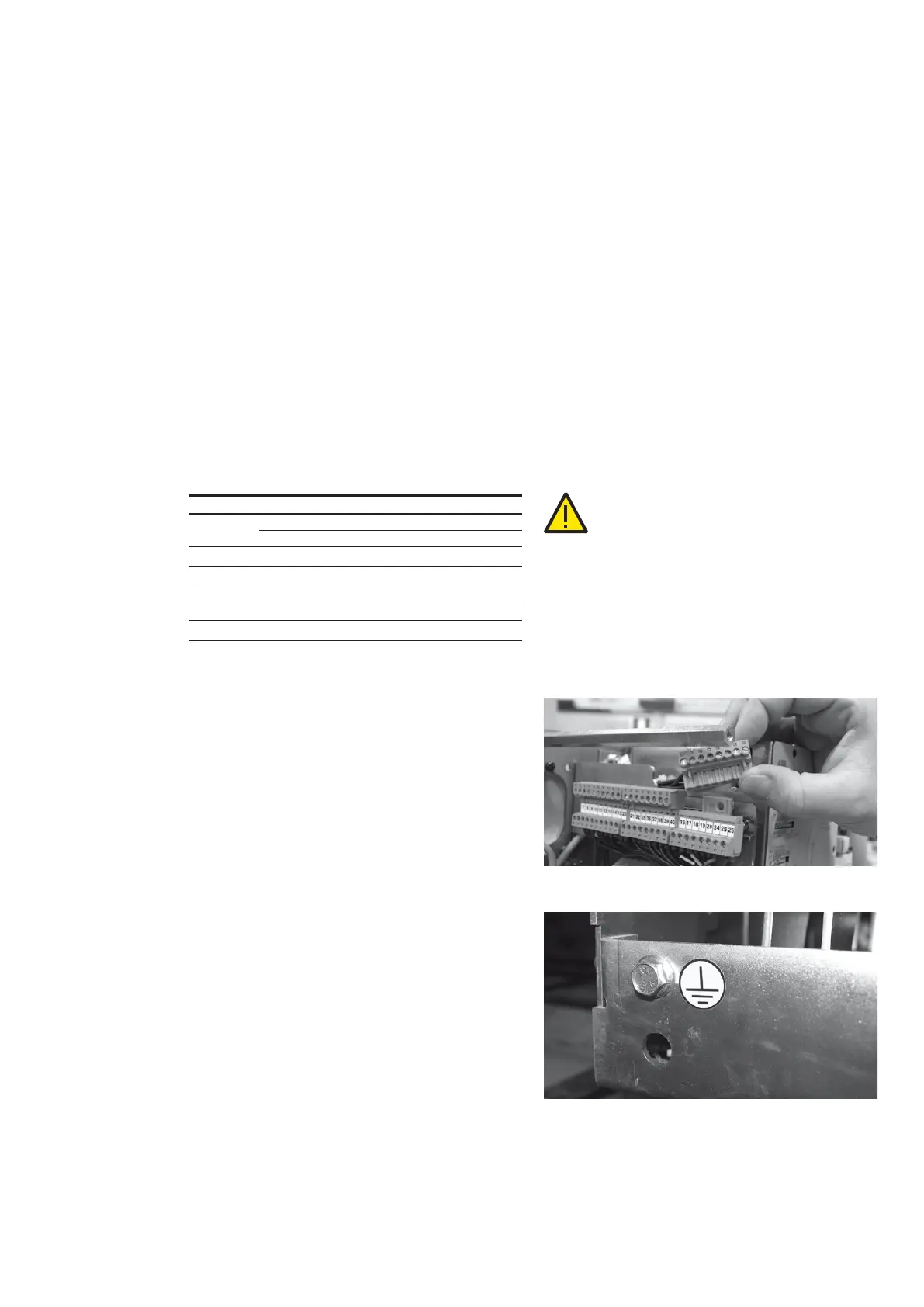

7.7 Earthing

Earth fixed version circuit breakers by means

of the special screw marked with the relative

symbol. Clean and degrease the area around

the screw corresponding to a diameter of about

30 mm. Use a conductor (busbar or cord) with a

cross-section conforming to the Standards in

force.

When the assembly is completed, cover the joint

with vaseline grease.

7.8 Connection of the auxiliary

circuits

The minimum cross-section of the wires used for

the auxiliary circuits must not be less than the one

used for the internal cabling.

Furthermore, they must be insulated for a 2 kV

test voltage at power frequency according to

standard IEC 60694 sect. 6.2.10.

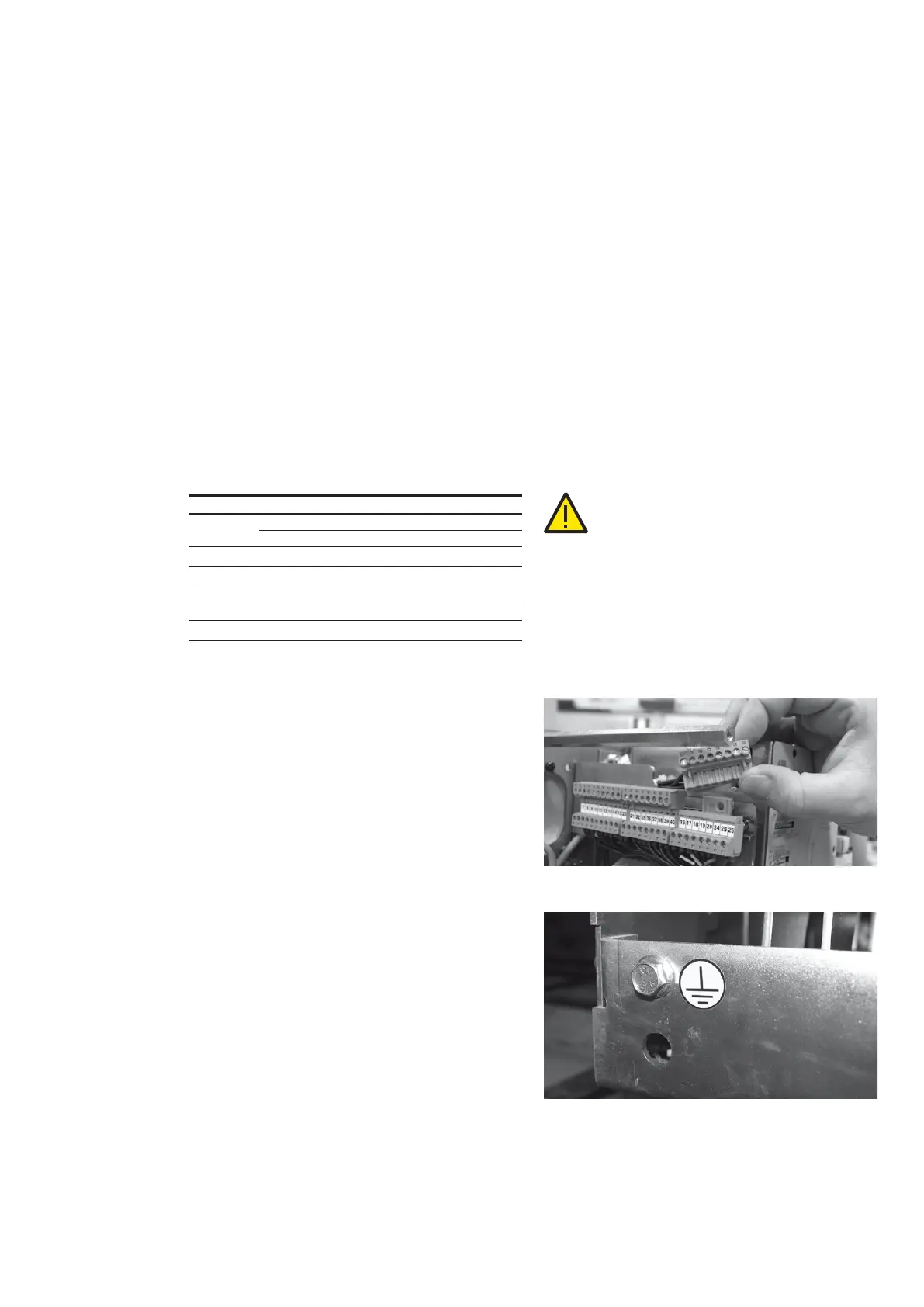

7.8.1 Fixed version circuit breakers

The auxiliary circuits of the circuit breaker must

be connected by means of modular terminals

installed under the cover.

The wires outside the circuit breaker must be

routed inside appropriately earthed metal tubes

or ducts.

7.8.2 Circuit breakers for ABB switchgear

The auxiliary circuits are fully wired in the factory

through to the connector. Please refer to the

wiring diagram of the switchgear for the

connections.

Figure 10

Figure 9

Loading...

Loading...