AIR COMPRESSORS

DIRECT & BELT DRIVEN MANUALS

COPYRIGHT ADENDORFF MACHINERY MART

10

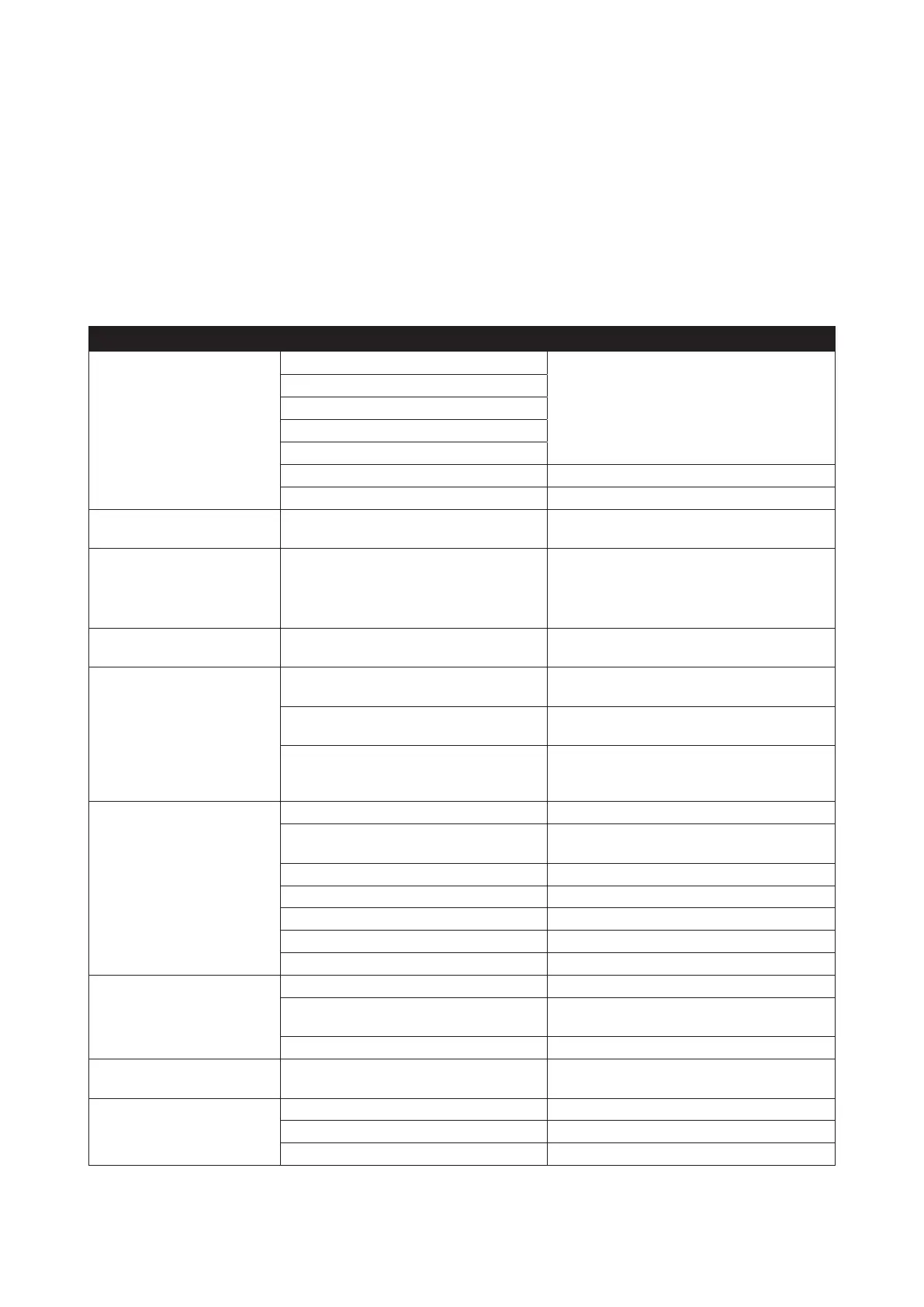

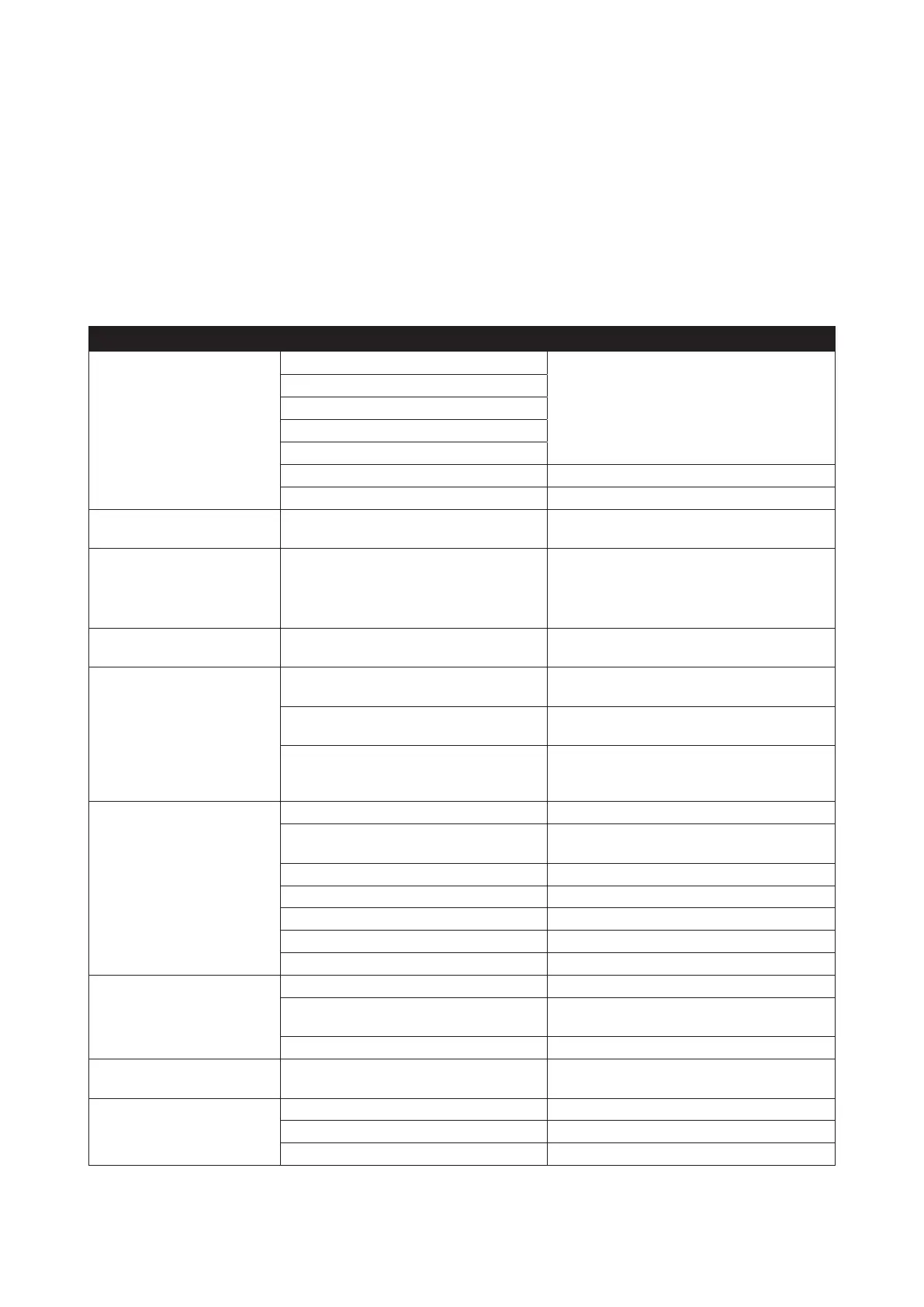

TROUBLESHOOTING CHART

IMPORTANT

I. Any remedial work that may be required must be carried out by a qualified electrician/engineer.

II. Disconnect from the mains supply before removing any parts from the compressor.

III. EmptyAirReceiverofairbeforedismantlinganypartofthecompressorunit’spressuresystem.

IV. If your compressor develops a fault do not use until the fault has been rectified.

SYMPTOM PROBABLECAUSE REMEDY

Compressor will not start auto-

matically

Fault in electrical installation Let an electrician check the electrical installation

Current supply failure

Voltage drop

Motor starter faulty

Motor incorrectly connected or faulty

Starter overload has tripped out Reset by depressing button

Pressure switch defective Have pressure switch changed by an electrician

Compressor unit will not stop

automatically

Pressure switch defective Contact Adendorff Machinery

Bleed valve under pressure

switch blows whilst compres-

sor is not running

Non-return valve leaking Replace

Bleed valve under pressure Non return valve stuck (NRV) open at junction

at the tank and the pump delivery pipe

Drain tank and remove inspection nut to clean

Non Return valve

Compressor unit starts, but

stops again after only a few

revolutions

Non-return valve leaking (compressor unit is

on load during start).

Disconnect from the mains supply and empty air

receiver. Clean or replace

Non-Return value blocked, possibly frozen up Thaw non-return valve out (unit must be installed

in frost-free place)

Solenoid valve leaking or defective (only

applies to certain models - where applicable

- and above)

Contact Adendorff Machinery

Unusual noise from compressor Bolts loose Tighten bolts

V-Belt flywheel or cooling coil touching belt

guard

Find place of contact and remedy fault

Flywheel loose Tighten flywheel

Unit installed on an unsuitable base Move unit to a more solid base

Bearings, piston rings or cylinder worn Contact Adendorff Machinery

Valve broken Contact Adendorff Machinery

Bearings of electric motor worn Contact Adendorff Machinery

Compressor unit starts and

stops more frequently than

usual

Large amount of condensation in air receiver Drain off condensation at least once a day/week

Leaks in control unit or inspection cover Locate leaks (by means of soapy water) and

repair

Too little pressure Contact Adendorff Machinery

Compressor unit starts when no

air is being used

Leaks in pipework system Locate and repair leaks

Electric motor too hot:

Maximum temperature 90°C

Operational voltage too low Call an electrician

Faults in electrical installation Contact Adendorff Machinery

Cooling fins of electric motor blocked by dirt Clean cooling fins

Loading...

Loading...