COPYRIGHT ADENDORFF MACHINERY MART COPYRIGHT ADENDORFF MACHINERY MART

AIR COMPRESSORS

DIRECT & BELT DRIVEN MANUALS

9

GENERAL ARRANGEMENT (DIRECT DRIVE MODEL)

I. Inspection Plug 8. Air Delivery Pipe 12a. On/Off Switch

2. Air Receiver 9. Electric Motor 12b. Pressure Switch

3. Oil Drain Plug 10. Air Bleed Pipe 12c. Saftey Valve

4. Oil Level Sight Glass 11. Non-return Valve 12d Air Bleed Valve

5. Oil Filler/Breather 12. Pressure Switch 12e. Receiver Pressure Gauge

6. Air Intake Filter 12f. Regulator Pressure Gauge

7. Air Compressor Pump 12g. Pressure Regulator

contact the Adendorff Service Department.

MAINTENANCE TIPS FOR AIR COMPRESSORS

• DRAINTHEMOISTUREFROMTHETANKDAILY!

• CHECKANDCHANGETHECOMPRESSOROIL–Ifyou’rerunningacompressorthatusesoil,youshouldbechecking

it on a daily basis to make sure that your machine is topped up. You should change you oil every 300-500 hours to

ensure maximum functioning of your air compressor.

• CHECKANDCHANGEAIRFILTERS-Havingadirtyairlterwillforcethecompressortoworkharderduetoaheavy

build-up of dust and dirt which will cause internal damage. You should check you air filter daily and change if

necessary. It is advisable that you change the air filter(s) after every six months and clean weekly.

• DONOTUSEEXTENSIONPOWERCORDS–thiswillinturncauseavoltagedropthuscausingtheelectricalmotor

to labour and the windings on the motor will burn out.

IMPORTANT TIP – rather plug the compressor at the wall plug on a separate circuit and use longer air-line hose

– applicable for single phase 230 V units. Three phase installations should be installed by a qualified electrician

directly at the power supply source.

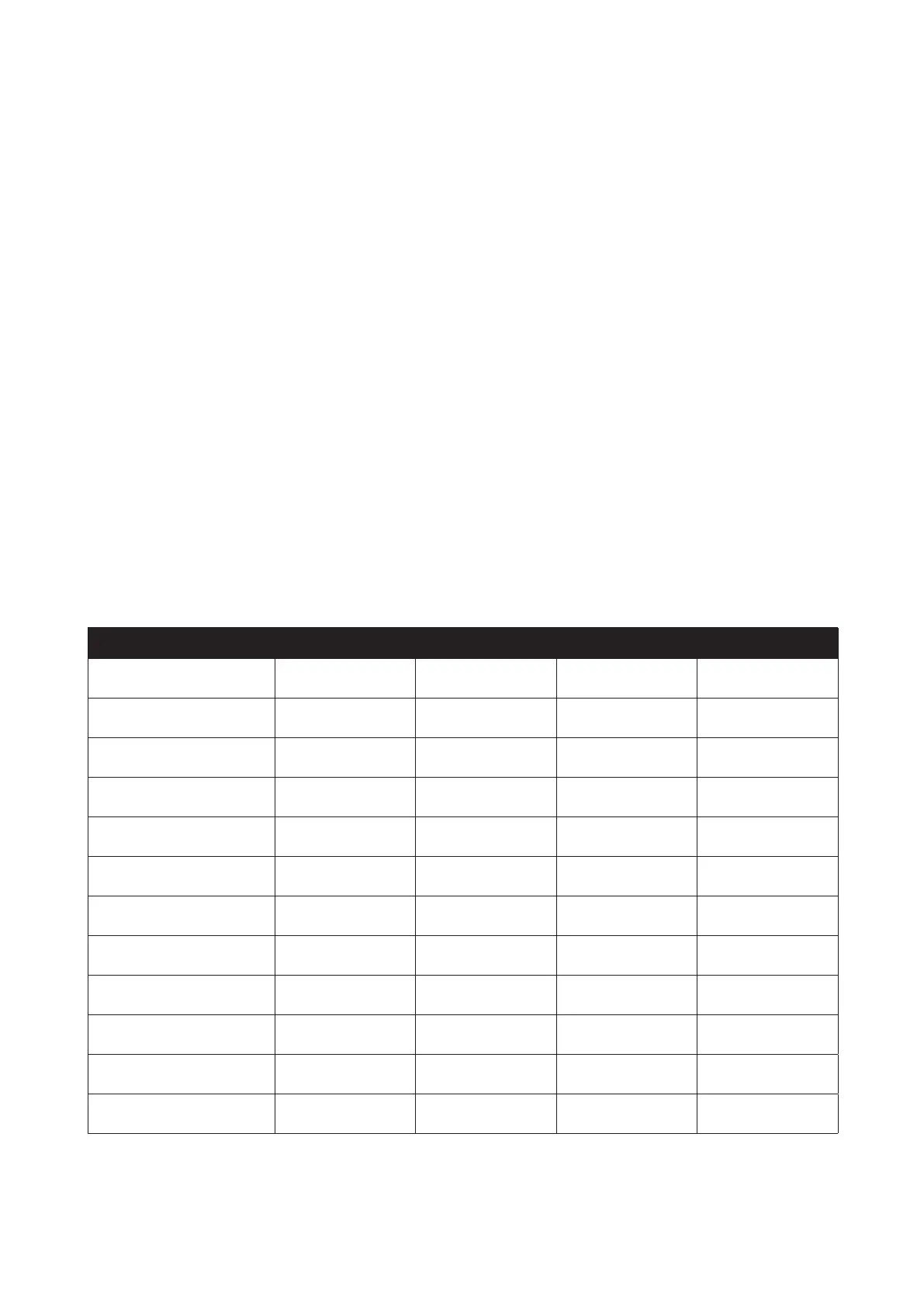

MAINTENANCE CHART

CHECK LIST

DAILY WEEKLY 6 MONTHLY NOTES

Oil level Check Change

Air Receiver Drain

Intake Filter Check/Clean Replace if necessary

Oil breather Check/Clean

Fan and cooling fins Clean

Inlet and outlet valves

If worn contact

Adendorff Machinery

Non Return Valve Clean Replace if worn

Belt Tension Check

Check adjust/ Replace

if worn

Does not apply to

direct drive

Big end bearings Check

If worn Contact

Adendorff Machinery

Main bearings Check

If worn Contact

Adendorff Machinery

Piston Rings

If worn Contact

Adendorff Machinery

Cylinder head bolts Check torque settings

If worn Contact

Adendorff Machinery

Loading...

Loading...