Instruction Manual

www.adsdental.com

- 5 -

WARNING

The separator tank lter is the only

component of the dry vacuum system

that should be accessed or serviced by the

owner. All other components and service

tasks must be performed by an authorized

technician qualied to service this vacuum

system. Images of additional system

components shown in this manual are for

informational reference only and are not

intended to indicate serviceable parts.

To ensure safe operation of this vacuum unit, the following

safety precautions must be observed:

● Read and understand all instructions fully before

operating the vacuum unit.

● For installation, comply with all local electrical and

safety codes, the National Electrical Code (NEC), and the

Occupational Safety and Health Act (OSHA).

● Protect the power cable from damage. Do not kink it or

let it contact sharp edges, oil, grease, heat, or chemicals.

● Ensure the power source matches the equipment

requirements.

● Disconnect all power and control lines before servicing

or maintaining the unit. Use lockout/tagout procedures.

● Do not service any parts while vacuum is running.

● Keep parts clean and protected during maintenance.

● Remove all tools, rags and loose parts before operation.

● Do not use ammable solvents for cleaning.

● Do not operate without the service panel in place.

● Do not operate in rooms with ammable or toxic fumes

present.

● Do not operate in ambient temperatures above 104°F

(40°C).

● The motor may be hot after recent use. Touch with

caution to avoid injury. This is normal at rated load.

● Inspect daily and correct any unsafe conditions.

● Inspect hoses before use. Ensure connections are secure.

Decommissioning of

Equipment

When taking ADS dental equipment out of service, proper

decommissioning and disposal procedures should be

followed in accordance with local regulations.

Electronic components such as circuit boards and electrical

cabling should be recycled as e-waste. Metal parts made of

aluminum, brass, steel, and iron are recyclable as scrap metal.

Molded plastic parts feature molding codes indicating the

plastic type and should be recycled accordingly.

The separator tank, drain lines, and extraction lines of ADS

vacuum systems are considered biohazardous and should be

handled with appropriate precautions during dismantling.

Appropriate personal protective equipment should be worn

when handling contaminated vacuum system components.

Any components that cannot be recycled should be

disposed of through appropriate waste streams. Please

contact ADS Customer Service for guidance regarding

material types and recycling/disposal options specic to your

ADS dental equipment.

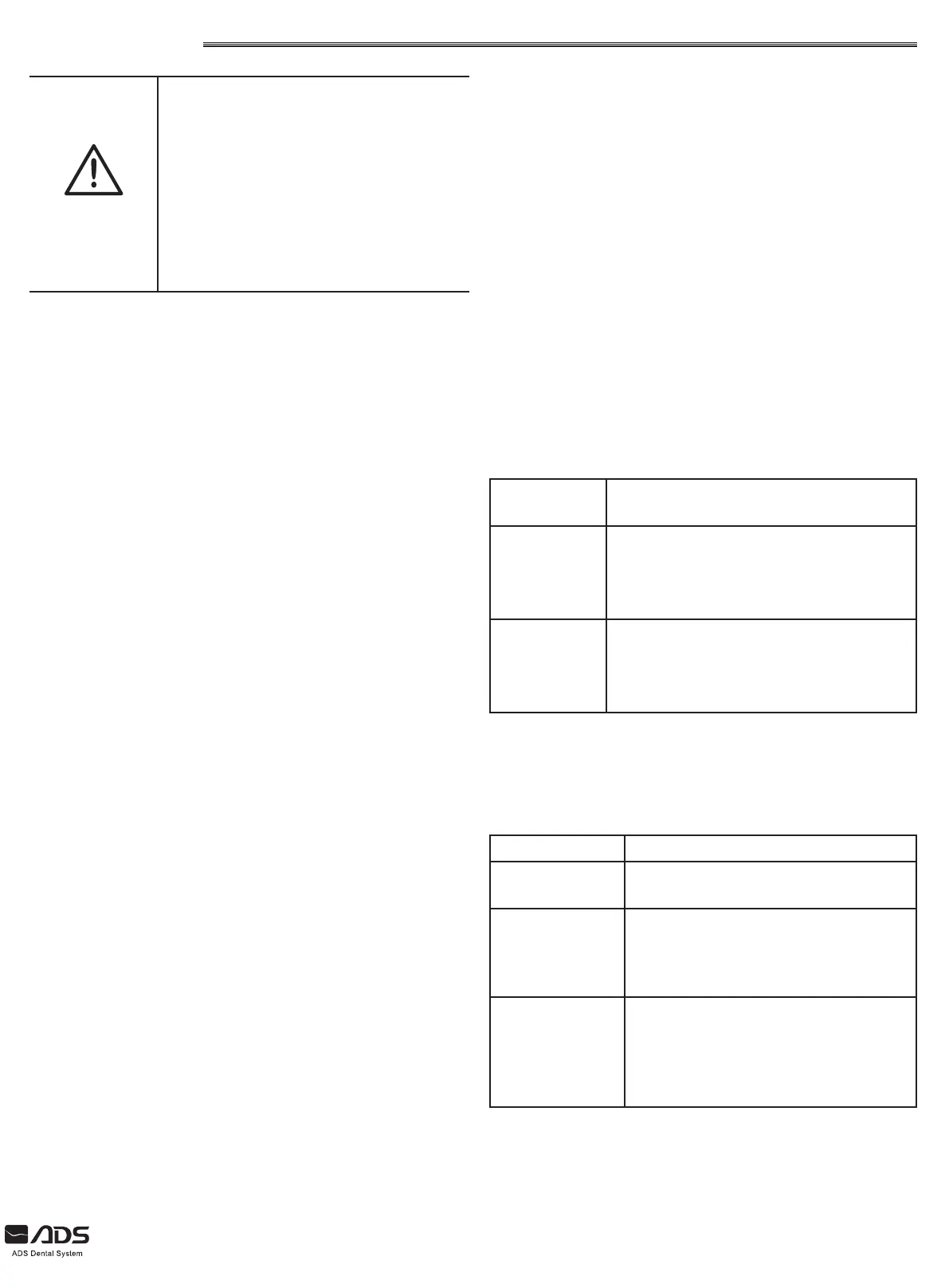

Environmental Requirements

To ensure proper function and prevent damage, ADS

equipment should be stored, transported, and operated

within the following temperature and humidity ranges:

Temperature/

Humidity

Specication

Storage/

Transportation

● Temperature: 32°F to 158°F (0°C to

70°C)

● Relative Humidity: Up to 90% (non-

condensing)

Operation

● Room Ambient Temperature: 40°F to

104°F (4°C to 40°C)

● Relative Humidity: Up to 80% (non-

condensing)

Product Safety Classications

To ensure safe operation, ADS equipment is designed and

tested to conform to the following international standards:

Type/Mode Classication

Electrical Shock

Protection

All ADS products with mains voltage

are Class I Equipment per IEC 60601-1.

Water Ingress

Protection

ADS products are rated IPX0 per IEC

60529, meaning they do not have

protection against water ingress. Avoid

exposure to water or other liquids.

Operation Mode

ADS products are designed for

continuous operation with a 50%

full load duty cycle per IEC 60601-

1. Intermittent rest periods prevent

overheating.

Loading...

Loading...