16 Aermec cod.

5167556_03 17.09

NRK 0200-0700

5. DESCRIPTION OF COMPONENTS

5.1. REFRIGERANT CIRCUIT

SCROLL COMPRESSORS

Rotary air-tight scroll type compressor, with vapour injection and two-pole electric

motor.

All compressors come with casing resistance, electronic thermal protection with

centralised manual resetting and twopole electric motor.

COOLING/HEATING EXCHANGER SYSTEM SIDE

Braze welded AISI 316 steel plate heat exchanger, insulated externally with closed cell

neoprene anticondensation material. When the unit is not running, it is protected

against formation of ice inside by an electric resistance.

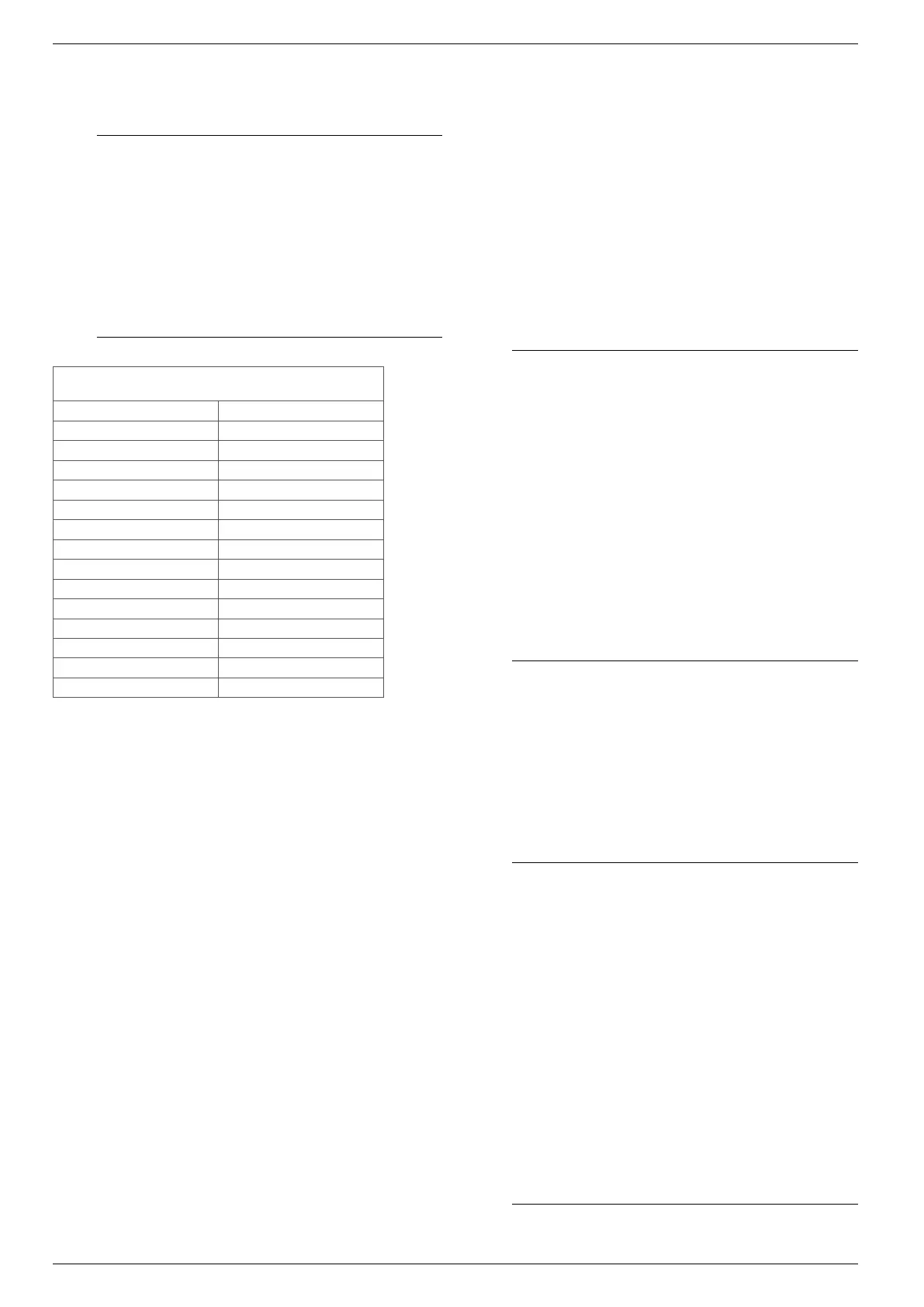

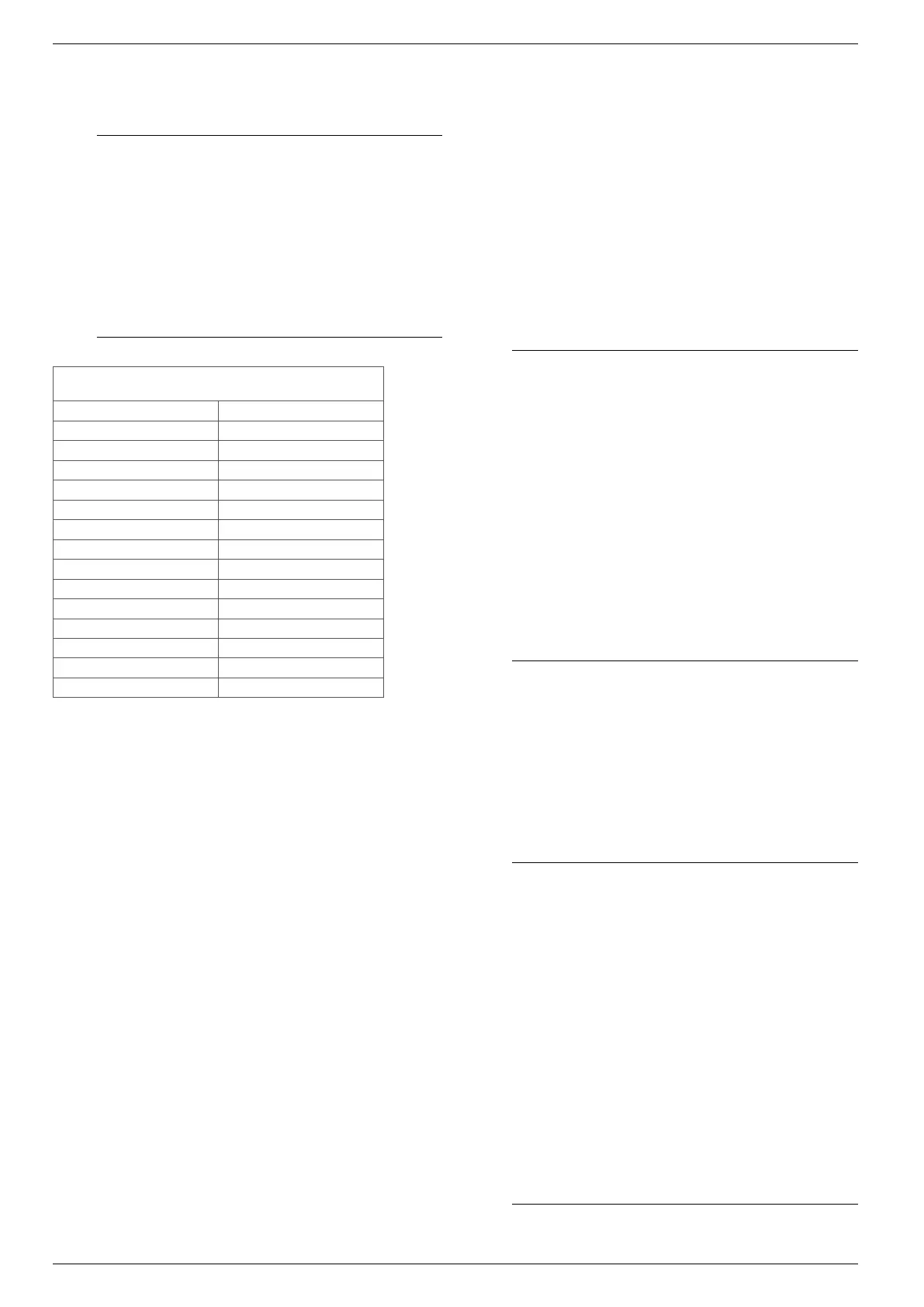

5.1.1. WATER FEATURES

System: Chiller with plate heat exchanger

PH 7,5-9

Electric conductivity 100-500μS/cm

Total hardness 4,5-8,5 dH

Temperature < 65°C

Oxygen content < 0,1 ppm

Max. glycol amount 50%

Phosphates (PO4) < 2ppm

Manganese (Mn) < 0,05 ppm

Iron (Fe) < 0,3 ppm

Alkalinity (HCO3) 70 - 300 ppm

Chloride ions (Cl-) < 50 ppm

Sulphate ions (SO4) < 50 ppm

Sulphide ion (S) none

Ammonium ions (NH4) none

Silica (SiO2) < 30ppm

SOURCE SIDE HEAT EXCHANGER

Finned pack heat exchanger made with copper pipes

and aluminium fins adequately spaced to ensure better

heat exchange performance.

EXCHANGER SYSTEM SIDE

Braze welded AISI 316 steel plate heat exchanger, insulated externally with closed cell

neoprene anti-condensation material. When the unit is not running, it is protected

against formation of ice inside by an electric resistance.

ECONOMIZER

Circuito economizzatore con scambiatore a piastre (AISI 316); consente di aumentare

le prestazioni soprattutto agli elevati rapporti di compressione, ad esempio in caso di

basse temperature esterne nel funzionamento invernale.

CYCLE REVERSING VALVE

4-way cycle reversing valve. Inverts the flow of refrigerant gas.

LIQUID STORAGE TANK

(always passed by)

Compensates the difference in volume between finned coil and plate exchanger,

retaining excess liquid.

DEHYDRATOR FILTER

Hermetic-mechanical with cartridges made of ceramic and hygroscopic material, able

to withhold impurities and any traces of humidity present in the cooling circuit.

NON-RETURN VALVES

Allows one-way flow of the refrigerant.

THERMOSTATIC VALVES

Mechanical valves, with external equaliser positioned at evaporator outlet, modulates

the flow of gas to the evaporator, depending on the heat load, in order to ensure a

correct heating level of the intake gas.

SOLENOID VALVES

The valve closes when the compressor switches off, blocking the flow of refrigerant

gas to the evaporator, recovery and the coil.

LIQUID SEPARATOR

Positioned on compressor intake for protection

against any return of refrigerant fluid, flooded start-up and functioning in the presen-

ce of liquids.

INDICATOR FOR LIQUID

Used to check presence of humidity in cooling circuit.

5.2. STRUCTURE AND FANS

SUPPORT STRUCTURE

Structure made of hot-dipped galvanised steel sheets, painted with polyester

powders, built to guarantee easy accessibility for service and maintenance.

STANDARD FANS

Axial fans with IP 54 degree of protection, external rotor, helical blades, housed in

nozzles, complete with accident-prevention protective screen. 6-pole electric motor

with built-in circuit breaker.

They are equipped as standard with condensation check via a device that continu-

ously adjusts the fans' speed.

LARGER FANS

Offer a useful head to avoid pressure drops

of the aeraulic system if the fans need to be channelled.

LARGER INVERTER FANS

(available only from size 0500 to 0700).

5.3. STANDARD HYDRAULIC CIRCUIT

WATER FILTERS

Equipped with steel filtering mesh, prevents the heat exchangers both of the system

side and the DHW/heating system side from clogging.

FLOW SWITCHES

They have the task of controlling that there is water circulation inside the heat

exchangers; if this is not the case, they block the unit.

AIR VENT VALVE

Mounted on the top of the hydraulic system; they discharge possible air pockets.

5.3.1. COMPONENTS OF HYDRAULIC CIRCUIT IN CONFIGURABLE VERSIONS

PUMPS

High or low static pressure.

It is possible to request a second pump to operate in standby for the first (twin

pumps) with high or low pressure levels. The pumps work in programmed rotation

and, in the event of a fault on the operating pump, switch-over is automatic.

EXPANSION VESSEL

With nitrogen pre-load membrane.

SAFETY VALVE

Equipped with a piped discharger, intervenes by discharging the over pressure in case

of anomalous pressures.

SYSTEM BUFFER TANK

Made of steel to reduce heat loss and to eliminate the formation of condensation,

insulated by thick polyurethane.

Supplied as per standard with 300W electric anti-freeze resistance (as low as -20°C

outside temperature - 5°C tank water temperature) controlled by anti-freeze probe

inserted in tank.

5.4. SAFETY AND CONTROL COMPONENTS

Loading...

Loading...