12

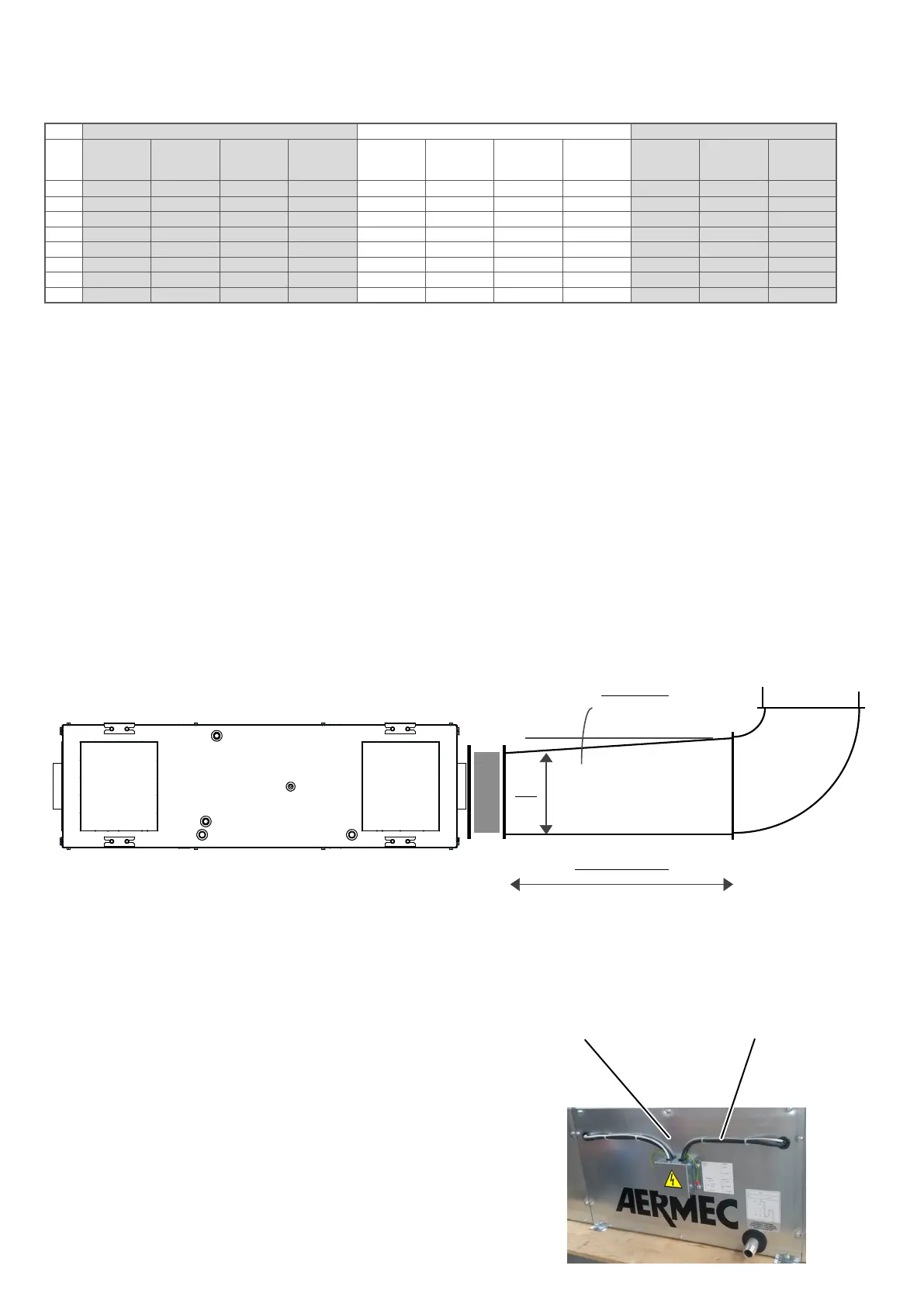

DIAMETER OF THE HYDRAULIC CONNECTIONS

AERAULIC CONNECTIONS

ELECTRICAL CONNECTIONS

INTERNAL COIL (W) EXTERNAL PROMISCUOUS COIL (MBF and MBF_X) EXTERNAL POST HEATING COIL (MBP)

Type Ø M coil inlet

connections

Ø M coil outlet

connections

Ø M conden-

sate drain

connections

Type Ø M coil inlet

connections

Ø M coil outlet

connections

Ø M conden-

sate drain

connections

Type Ø M coil inlet

connections

Ø M coil outlet

connections

030 H/C 1/2” 1/2” 1/2” - - - - Post-Heating 1/2” 1/2”

050 H/C 1/2” 1/2” 1/2” - - - - Post-Heating 1/2” 1/2”

070 H/C 1/2” 1/2” 1/2” - - - - Post-Heating 1/2” 1/2”

100 H/C 1/2” 1/2” 1/2” - - - - Post-Heating 1/2” 1/2”

140 Hot 3/4” 3/4” 1” H/C 3/4” 3/4” 1” Post-Heating 1/2” 1/2”

200 Hot 1” 1” 1” H/C 3/4” 3/4” 1” Post-Heating 1/2” 1/2”

300 Hot 1” 1” 1” H/C 1” 1” 1” Post-Heating 3/4” 3/4”

400 Hot 1” 1” 1” H/C 1” 1” 1” Post-Heating 3/4” 3/4”

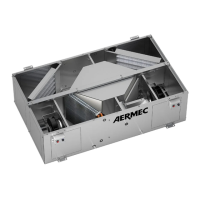

MAX 7°

MIN 2.5 A

A

GENERAL STANDARDS

• prepare adequate brackeng to support the ducts so that the unit does not bear their weight

• connect the ow and recovery vents to the ducts placing an-vibraon joints in between (oponal)

• provide an earth cable acng as a bridge on the an-vibraon joint to guarantee electrical equipotenality between the duct and the unit

• provide, before bends and branches, the ow duct with a straight secon measuring at least 2.5 mes the smallest side of the duct to prevent loss

of fan performance

• make sure that the slope of the ducng branching secons does not exceed 7°.

GENERAL STANDARDS

Loading...

Loading...