e. Program the current of the selected output to the

High Range Full Scale Current value and the

output voltage to 50.5 volts by sending the

following strings:

ISET <ch>, <0.5(25W) or 2(50W)>

VSET <ch>, <50.5>

f. Repeat the load for High Range Full Scale current

and 50 volts indicated on the front panel display.

Check that the CC annunciator is on. If it is not,

adjust the load so that the output voltage drops

slightly.

g. Record the output current reading (DVM reading ÷

10).

h. Adjust the transformer to 6% above the nominal

line voltage.

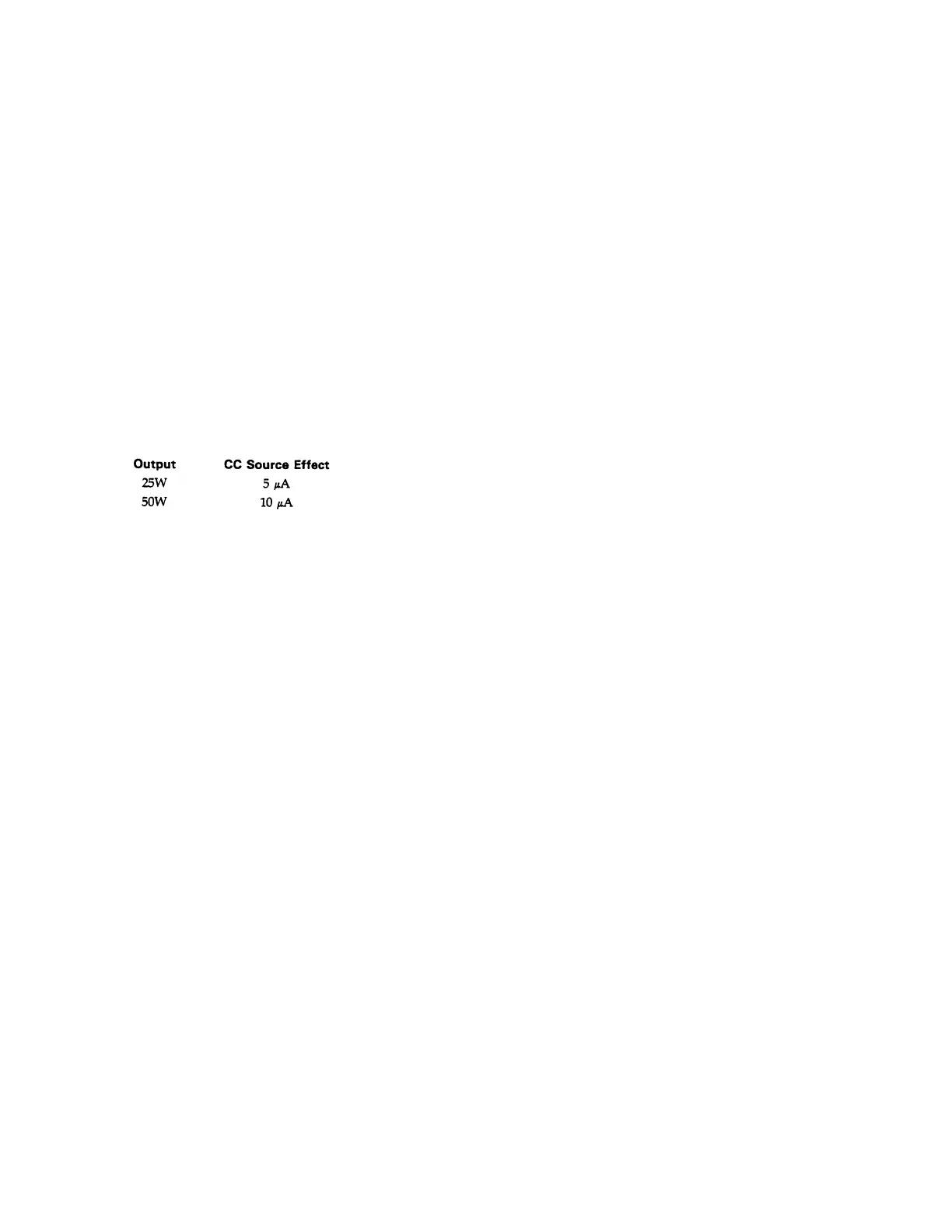

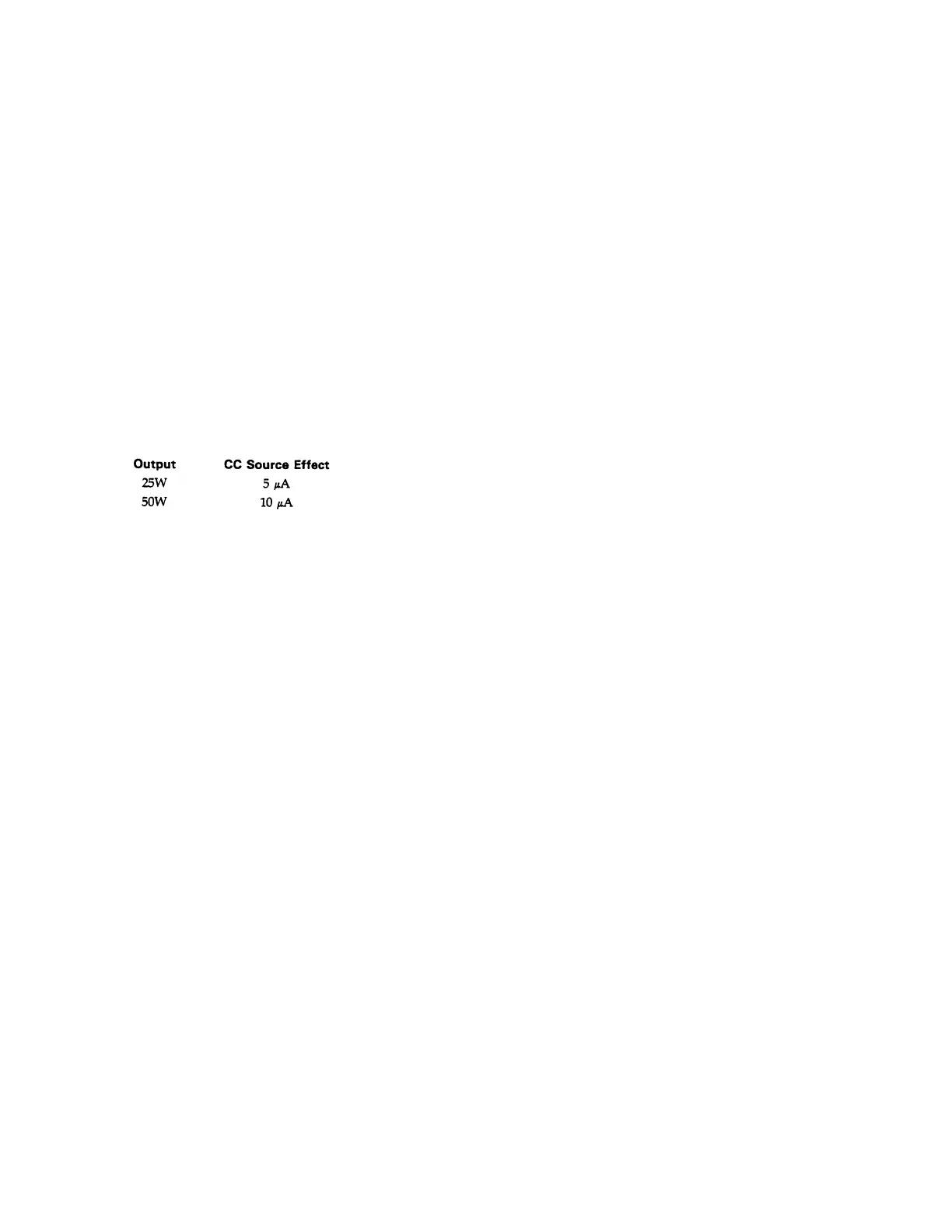

i. Record the output current reading again. The

difference in the current readings in steps g and I is

the CC source effect and should not exceed the

values listed below for the particular output being

tested.

j. Repeat this test (steps a through I) for each output

in your supply.

3-25 CC RMS Noise. This test measures the rms noise in the

output when operating in the constant current mode.

a. Turn off the supply and connect the output to be

tested as shown in Figure 3-3 with an rms voltmeter

connected across the output, the load switch closed,

and the short switch opened.

b. Turn on the supply and select the output to be

tested (OUTPUT SELECT switch on front panel).

c. Program the current of the selected output to the

High Range Full Scale Current value and the

output voltage to 50.5 volts by sending the

following strings:

ISET <ch>, 0.5

VSET <ch>, 16

NOTE

This test must be performed with a resistive load only. The use

of an electronic load will invariably inject extra ripple and may

cause the CC RMS noise to be out of specification.

d. Adjust the load resistor to about 30 ohms so that

the output voltage is close to 15 volts. Check that

the CC annunciator is on.

e. Note that the reading on the rms voltmeter should

be less than 5 mV (equivalent to 0.1 mA RMS).

f. Repeat this test (steps a through e) for each output

in your supply.

3-26 Performance Test Record

All of the performance test specifications for the power

supply are listed in Tables 3-3 and/or 3-4. Table 3-3 covers

the 25 watt outputs; Table 3-4 covers the 50 watt outputs.

3-27 EXTENDED TESTS

These tests are similar to the Performance Tests except they

have a much longer duration, are conducted with controlled

temperature conditions or test supplemental characteristics.

3-28 Output Drift

The tests are divided into two parts: short term and long

term drift. For all drift tests, place the supply to be tested in

a temperature chamber or in a temperature controlled

environment such as a standards room.

3-29 Short Term Voltage Drift Test. This test measures the

change in output voltage within the first 30 minutes of a

change in the line voltage or the load.

a. Turn off the supply and connect the output to be

tested as shown in Figure 3-3 with the load switch

closed and the short switch opened. Connect the

supply to the ac power line through a variable

voltage transformer and adjust it for the nominal

value.

b. Turn on the supply and select the output to be

tested (OUTPUT SELECT key on front panel).

c. Program the selected output to 50 volts and 0.515

Amps(25W) or 1.03 Amps(50W)

d. Adjust the load for 0.5 Amps(25W) or 1 Amp(50W)

as read on the display. Check that the CV

annunciator is on.

e. Adjust the transformer to 13% below the nominal

line voltage.

f. Wait 30 minutes and record the output voltage

value again. The difference in the readings taken in

steps I and j should be less than 2 millivolts.

g. Adjust the transformer to 6% above the nominal

line voltage.

h. Wait 30 minutes and record the output voltage

value again. The difference in the readings taken in

steps f and h should be less than 2 millivolts.

i. Open the load switch and immediately record the

output voltage reading.

j. Wait 30 minutes and again record the output

voltage reading. The difference in the readings

taken in steps and j should be less than 2 volts.

k. Repeat steps a through j for each output in your

supply.

3-30 Short Term Current Drift Test. This test measures the

change in output current within the first 30 minutes of a

change in the line voltage or the load. Place the supply to be

tested in a temperature chamber or in a temperature

controlled environment such as a standards room.

a. Turn off the supply and connect the output to be

tested as shown in Figure 3-3 with the DVM

connected across the current monitoring resistor,

the load switch closed, and the short switch

opened. Connect the supply to the ac power line

through a variable voltage transformer and adjust it

for the nominal value.

3-10

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Loading...

Loading...