i. Repeat steps f and g. Note the difference between

the values read before and after the temperature

change. The difference between the output voltage

DVM readings should be less than 16 mV. The

difference between the readback voltage should be

less than the change in output ± 15 mV.

j. Repeat steps a through I for each output in your

supply.

3-35 Output Current and Readback Current TC

a. Repeat steps a through d of paragraph 3-34.

b. Set the temperature chamber to 30 degrees C and

allow 30 minutes for the output to stabilize.

c. Record the output current (DVM reading ÷ 0.1

(Shunt resistance)).

d. Readback the output current over the GPIB and

record the value.

e. Increase the temperature to 40 degrees C and wait

30 minutes for the output to stabilize.

f. Repeat steps c and d. Note the difference between

the values read before and after the temperature

change. The differences in output current should

not be more than 240

µ

A(25W) or 1.2 mA(50W).

The difference between the readback currents

should be less than the change in output ± 265

µ

A(25W) or 1.15 mA(50W).

g. Repeat steps a through f for each output in your

supply.

3-36 Negative Current Limit ( - CC) Readback TC

a. Repeat steps a through d of paragraph 3-22.

b. Set the temperature chamber to 30 degrees C and

allow 30 minutes for the output to stabilize.

c. Record the negative current limit value (DVM

reading x 10).

d. Readback the current over the GPIB and record

this value.

e. Increase the temperature to degrees C and wait 30

minutes for the output to stabilize.

f. Repeat steps c and d. Note the difference between

the values read before and after temperature

change. The differences should not be more than

the change I the sink current ± 265 µA(25W) or 1.15

mA(50W).

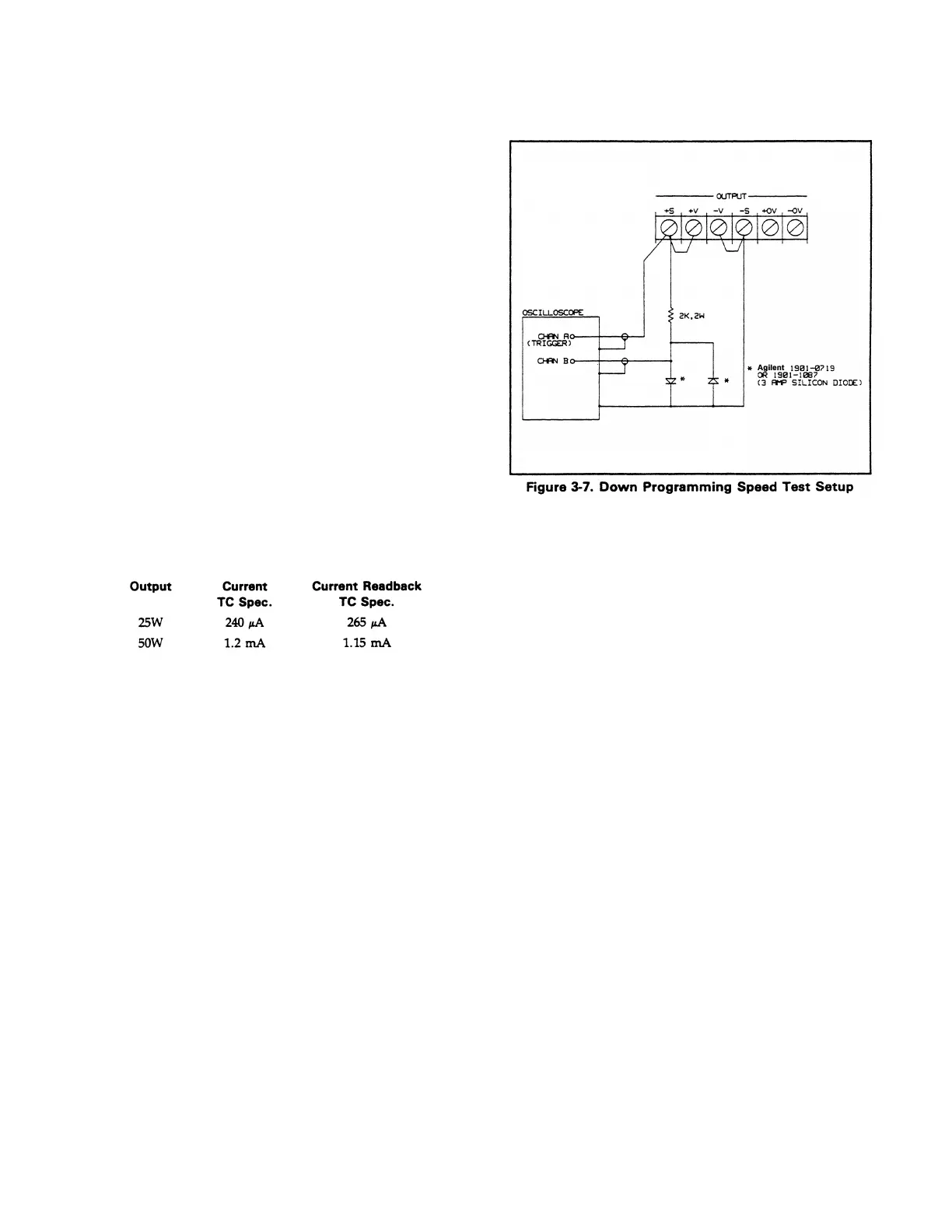

3-37 CV Down Programming Speed. This test measures

the time required for the output voltage to fall 37% of the

High Range Full Scale Voltage (time constant). Also

measured is the time an output takes to change from full

scale to zero volts and settle within 50 mV (response time).

a. Turn off the supply and connect the output to be

tested as shown in Figure 3-7.

b. Turn on the supply and select the output to be

tested (OUTPUT SELECT key on the front panel).

c. First, program the selected output to zero volts by

sending the string:

VSET <ch>, 0

d. Using Channel A on the oscilloscope, set the

volts/division switch to 10 V/div, dc coupled and

position the trace on the bottom horizontal line.

Using Channel B on the oscilloscope, set the

volts/division switch to 50 mV/div dc coupled and

position the trace on the bottom horizontal line.

e. Program the output voltage in a loop which

alternately programs the output voltage between 0

and 50 volts by running the program listed below.

10 OUTPUT 705;”ISET <ch>, <0.515(25W)

or 1.03(50W) >

20 OUTPUT 705;”VSET <ch>,0”

30 WAIT 0.05

40 OUTPUT 705;”VSET <ch>, 50”

50 WAIT 0.05

60 GOTO 20

70 END

NOTE

The tested output’s CV annnciator should remain on at all

times while the test is in progress.

f. Observe Channel A on the oscilloscope and adjust

for a stationary waveform by using Channel A as

the trigger source set to trigger on a negative edge.

Be sure to trigger as lose as possible to the time

when the output voltage just begins to fall.

3-12

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Loading...

Loading...