1-10

pl

above 100% rated output. Limit

our pro

rammin

volta

e to 10 Vdc.

Remote Pro

rammin

Connections. Remote pro

rammin

requires chan

in

settin

s of the switch and connectin

external

volta

es to + and - terminals of "CV" or "CC" on the rear panel.

An

noise picked up on the pro

rammin

leads will appear on the

suppl

's output and ma

de

rade re

ulation. To reduce noise

pick-up, use a twisted or shielded pair of wires for pro

rammin

,

with the shield

rounded at one end onl

. Do not use the shield as

a conductor.

Notice that it is possible to operate a power suppl

simulta-

neousl

in the remote sensin

and the remote analo

pro

ram-

min

modes.

Remote Pro

rammin

, Constant Volta

e. Fi

ure 6 shows the

rear panel switch settin

s and terminal connections for remote-

volta

e control of output volta

e. A 1 Vdc chan

e in the remote

pro

rammin

volta

e produces a chan

e in output volta

e (volt-

a

e

ain) as follows: E3614A: 0.8 Vdc, E3615A: 2 Vdc, E3616A:

3.5 Vdc, E3617A: 6 Vdc

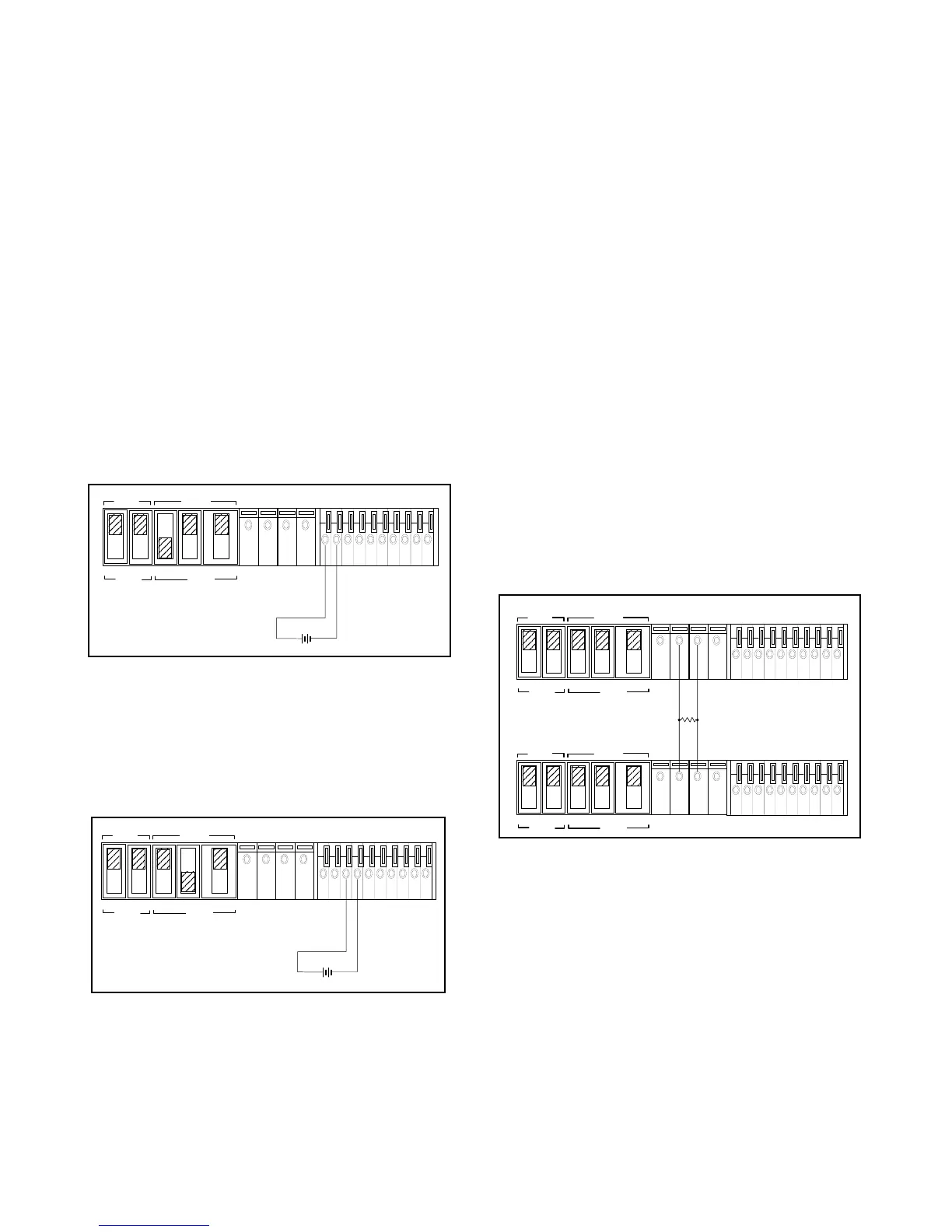

Fi

ure 6. Remote Volta

e Pro

rammin

, Constant

Volta

e

Remote Pro

rammin

, Constant Current. Fi

ure 7 shows the

rear panel switch settin

s and terminal connections for remote-

volta

e control of output current. A 1 Vdc chan

e in the remote

pro

rammin

volta

e produces a chan

e in output current (cur-

rent

ain) as follows: E3614A: 0.6 Adc, E3615A: 0.3 Adc,

E3616A: 0.17 Adc, E3617A: 0.1 Adc

Fi

ure 7. Remote Volta

e Pro

rammin

, Constant

Current

Remote Pro

rammin

Speed. See the table of Specifications,

pa

e 1-5.

MULTIPLE-SUPPLY OPERATION

Normal parallel and auto-parallel operation provides increased out-

put current while normal series and auto-series provides increased

output volta

e. Auto-trackin

provides sin

le control of output volt-

a

e of more than one suppl

. You can set up the unit for multiple-

suppl

operation b

chan

in

the settin

s of the rear panel switch

and connectin

the leads from the rear panel terminals to the load.

Solid conductors of 0.75 to 1.5 mm

2

can be connected to the rear

panel terminals b

simpl

push fittin

. Thinner wires or conductors

are inserted into the connection space after depressin

the oran

e

openin

lever.

NORMAL PARALLEL OPERATION

Two or more power supplies bein

capable of CV/CC automatic

cross over operation can be connected in parallel to obtain a total

output current

reater than that available from one power suppl

.

The total output current is the sum of the output currents of the

individual power supplies. The output of each power suppl

can

be set separatel

. The output volta

e controls of one power sup-

pl

should be set to the desired output volta

e; the other power

suppl

should be set for a sli

htl

hi

her output volta

e. The sup-

pl

with the hi

her output volta

e settin

will deliver its constant

current output, and drop its output volta

e until it equals the out-

put of the other suppl

, and the other suppl

will remain in con-

stant volta

e operation and onl

deliver that fraction of its rated

output current which is necessar

to fulfill the total load demand.

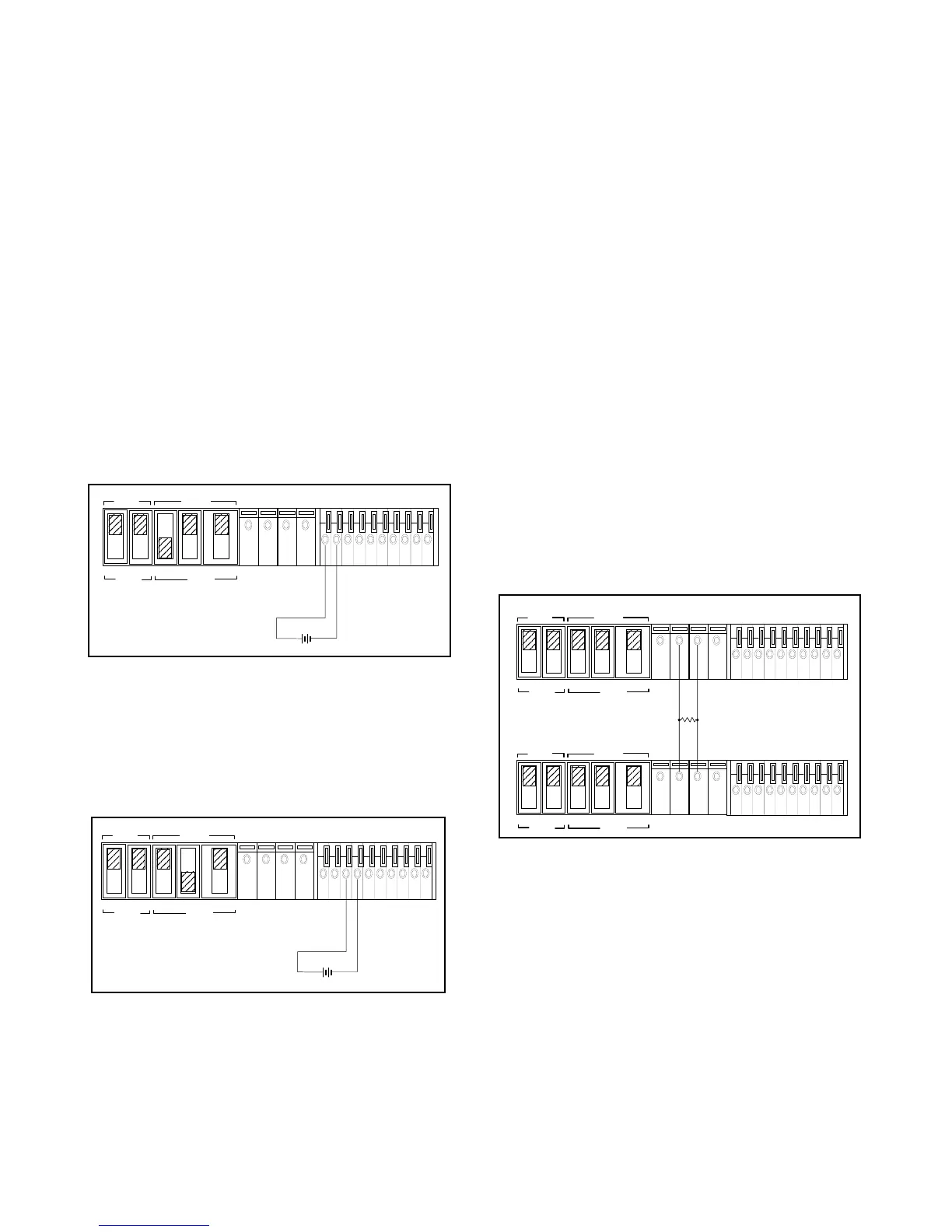

Fi

ure 8 shows the rear panel switch settin

s and terminal con-

nections for normal parallel operation of two supplies.

Fi

ure 8. Normal Parallel Operation of Two Supplies

AUTO-PARALLEL OPERATION

Auto-parallel operation permits equal current sharin

under all load

conditions, and allows complete control of output current from one

master suppl

. The control unit is called the master; the controlled

units are called slaves. Normall

, onl

supplies havin

the same

model number should be connected for auto-parallel operation,

since the supplies must have the same volta

e drop across the cur-

rent monitorin

resistor at full current ratin

. The output current of

each slave is approximatel

equal to the master's. Fi

ure 9 and Fi

-

ure 10 show the rear panel switch settin

s and terminal connections

for auto-parallel operation of two supplies and three supplies.

MASTER

SLAVE

CV CC SENSE

LOCAL

REMOTE

OUT

+S

-S

+

_

CV CC

VREF

A1 A2 A3 A4 A5

+

+

M/S 1 M/S 2

_

_

NOTE:

See the supplementar

Manual, if

ou are not usin

isolated pro

rammin

volta

e source.

MASTER

SLAVE

CV CC SENSE

LOCAL

REMOTE

OUT

+S

-S

+

_

CV CC

VREF

A1 A2 A3 A4 A5

+

+

M/S 1 M/S 2

_

_

NOTE:

See the supplementar

Manual, if

ou are not usin

isolated pro

rammin

volta

e source.

MASTER

SLAVE

CV CC SENSE

LOCAL

REMOTE

OUT

+S -S

+

_

CV CC

VREF

A1 A2 A3 A4 A5

+

+

M/S 1 M/S 2

__

MASTER

SLAVE

CV CC SENSE

LOCAL

REMOTE

OUT

+S

-S

+

_

CV CC

VREF

A1 A2 A3 A4 A5

+

+

M/S 1 M/S 2

_

_

POWER SUPPLY

POWER SUPPLY

LOAD

Loading...

Loading...