7

PlateLoc Thermal Microplate Sealer

Optimizing seal parameters

Reference for Optimal Thermal Microplate Sealing

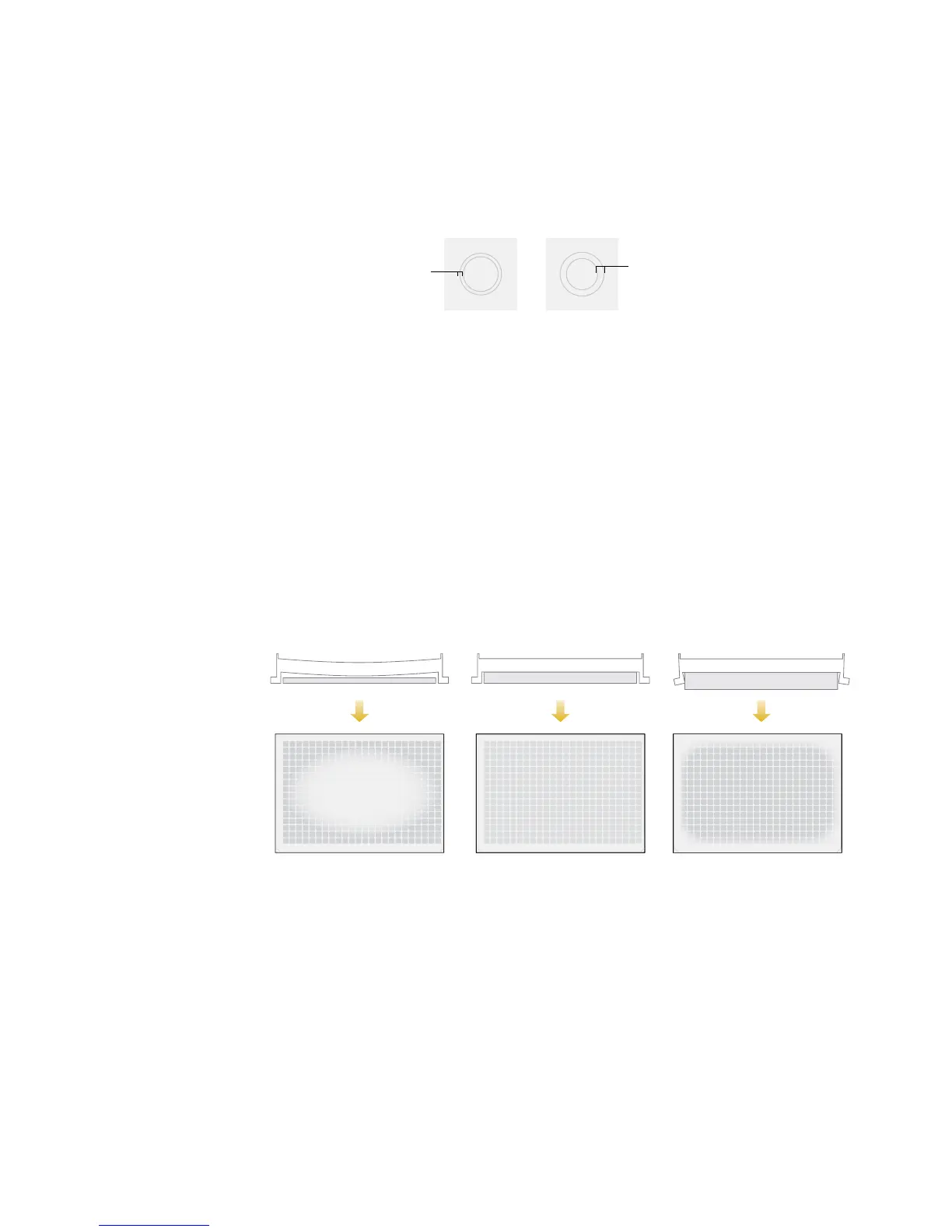

If the well impressions on the seal are significantly thicker than the chimney

wall (as shown in Figure 9), decrease the sealing temperature or duration.

Thick impressions may indicate excessive melting of the seal, causing the seal

to be difficult to remove and the resealing capacity reduced.

Figure 9 Evaluating rim width of seal. L: Good impression, with

thin, defined edge of chimney/

rim. R: Poor impression, with increased width.

Issues related to inserts

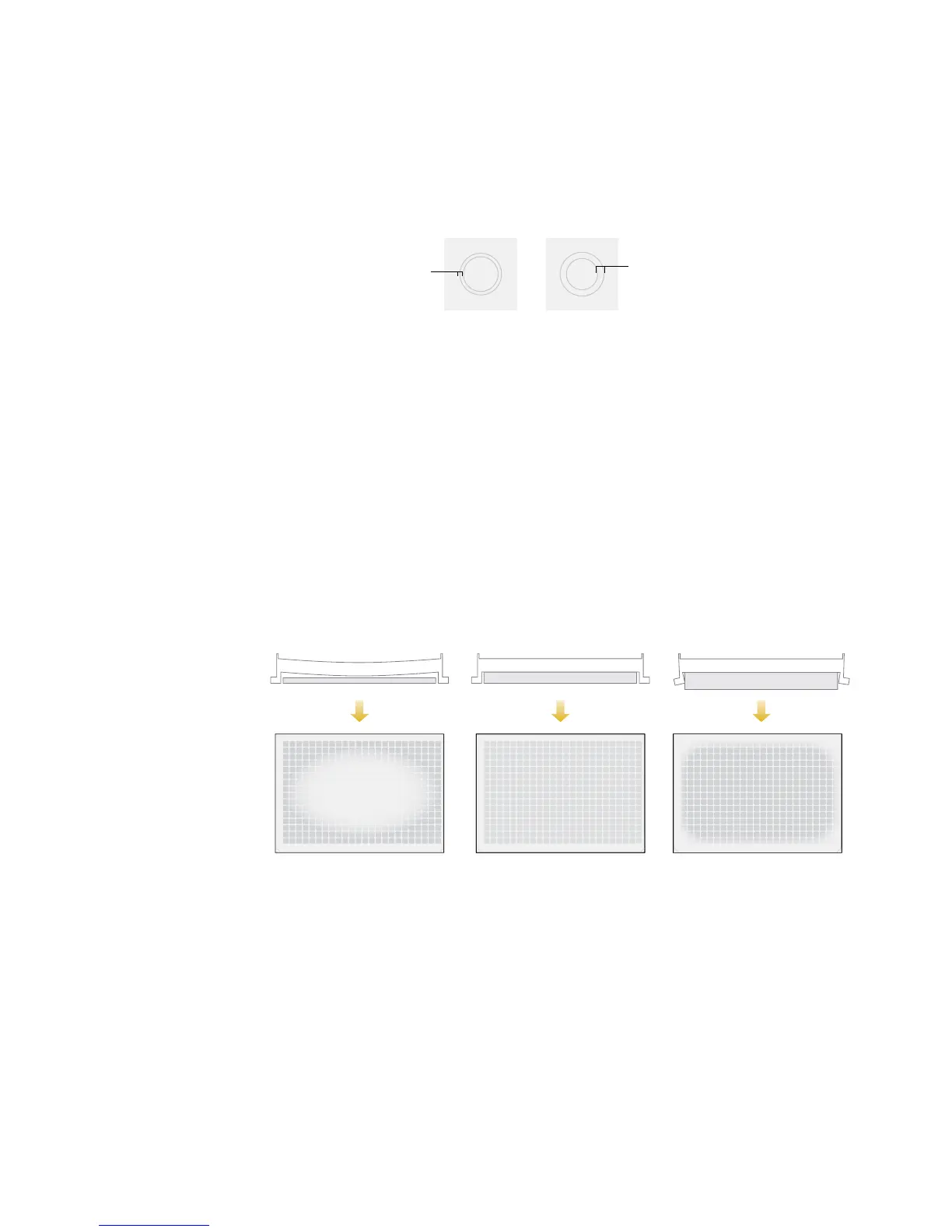

The hot plate is a heated metal surface that presses the seal onto the

microplate. For optimal sealing, the microplate needs to be firmly supported so

that it does not bend during the sealing process, often requiring use of an

insert to keep it flat. Figure 10 illustrates the effect of insert height on

microplate sealing. Left: if the insert is too thin, the center of the microplate

will bend downward during sealing, leading to good sealing around the edges,

but poor sealing in the middle of the microplate. Center: if the insert is the

correct thickness, the entire microplate surface will be sealed properly. Right:

if the insert is too thick, the edges of the microplate will bend downward

during sealing, resulting in good sealing in the middle of the microplate, but

poor sealing around the edges.

Note: Thick

er inserts are preferred over inserts that are too thin.

Figure 10 The effect of using inserts on microplate sealing. L: Insert too thin; C: Insert correct

heig

ht; R: Insert too thick.

Approximately same

thickness as chimney

wall

Thicker than chimney wall

Loading...

Loading...