3

Safety information

G5585B PlateLocThermal Microplate Sealer Quick Guide

General precautions

For the general safety precautions, the intended product use statement, and the list of

safety labels, see the Automation Solutions Products General Safety Guide.

Chemical hazards

To avoid potential injury, do not use chemicals that have low flash points in the

PlateLoc Sealer. Such chemicals include reagents that are used in radioactive

scintillation proximity assays (SPAs) and solvents, including alcohols.

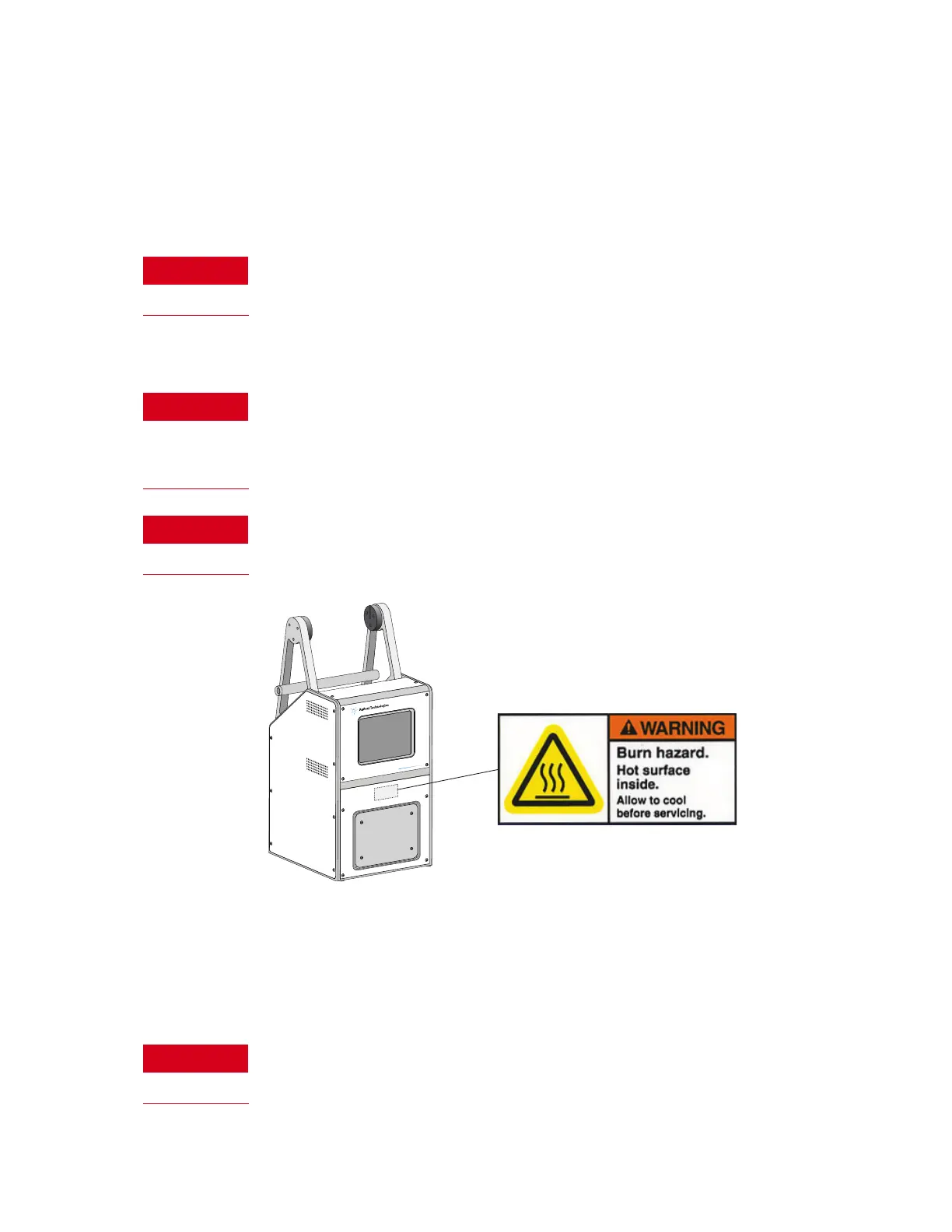

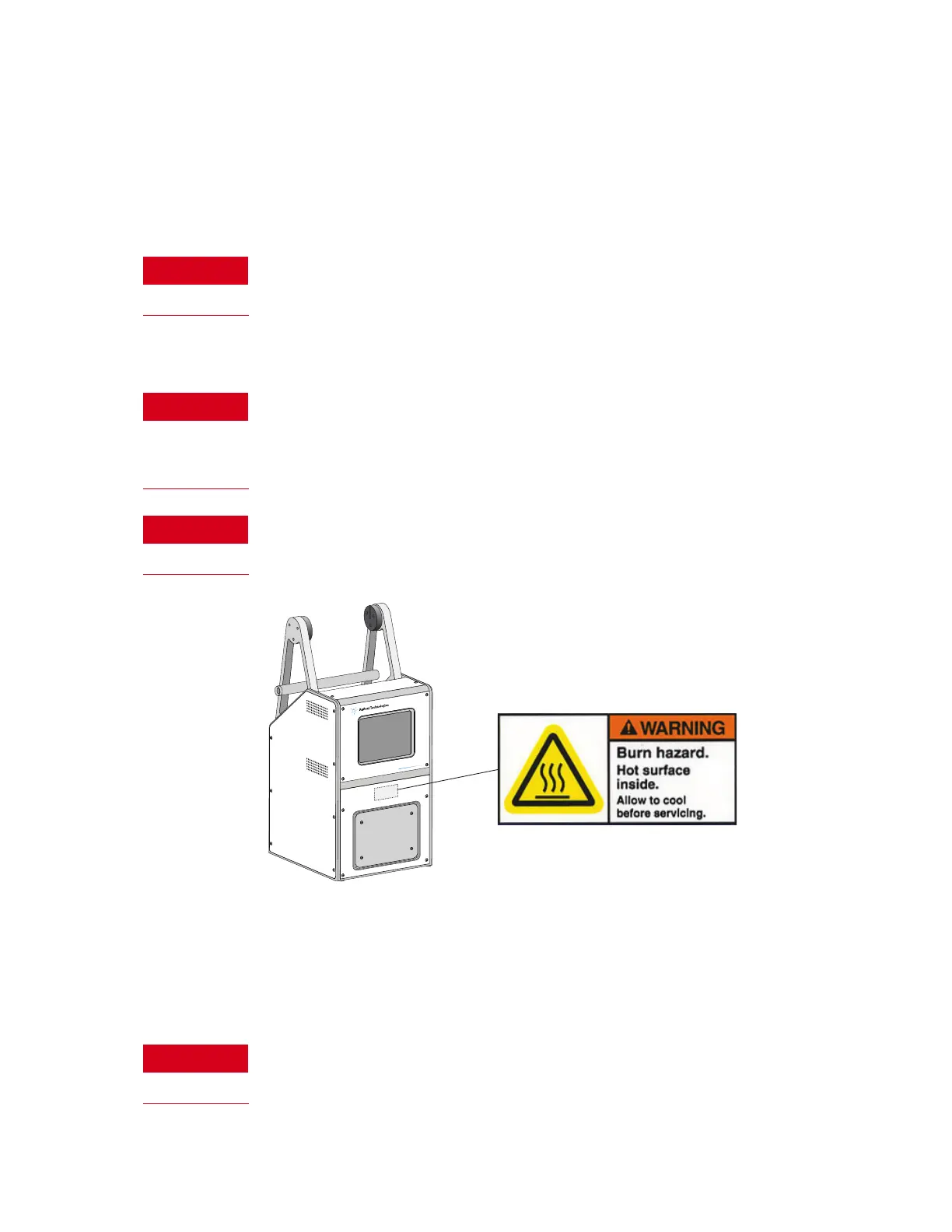

High-temperature hazard

The hot surfaces in the PlateLoc Sealer can cause a burn injury. Do not touch the

PlateLoc Sealer or pry open the door while it is in operation. Use care when

accessing the PlateLoc Sealer interior after the device is warmed up. Do not reach

into the PlateLoc Sealer when it is warmed up to a high temperature. Do not touch

the hot plate with your bare hands.

A freshly sealed microplate might still be hot from the sealing process. To prevent

potential injury, use caution when removing a sealed microplate from the PlateLoc

Sealer.

Moving-parts hazards

The PlateLoc Sealer contains moving parts that can cause injury. Under normal

operating conditions, the PlateLoc Sealer is designed to protect you from the moving

parts. The door sensor is designed so that the seal cycle cannot start unless the door is

closed.

Do not disable the door sensor or attempt to access the interior of the device through

any other openings. Exposure to the moving parts, such as the heated metal plate

(hot plate) or the seal-cutting blade can cause severe injuries.

PlateLoc

Loading...

Loading...