10 11

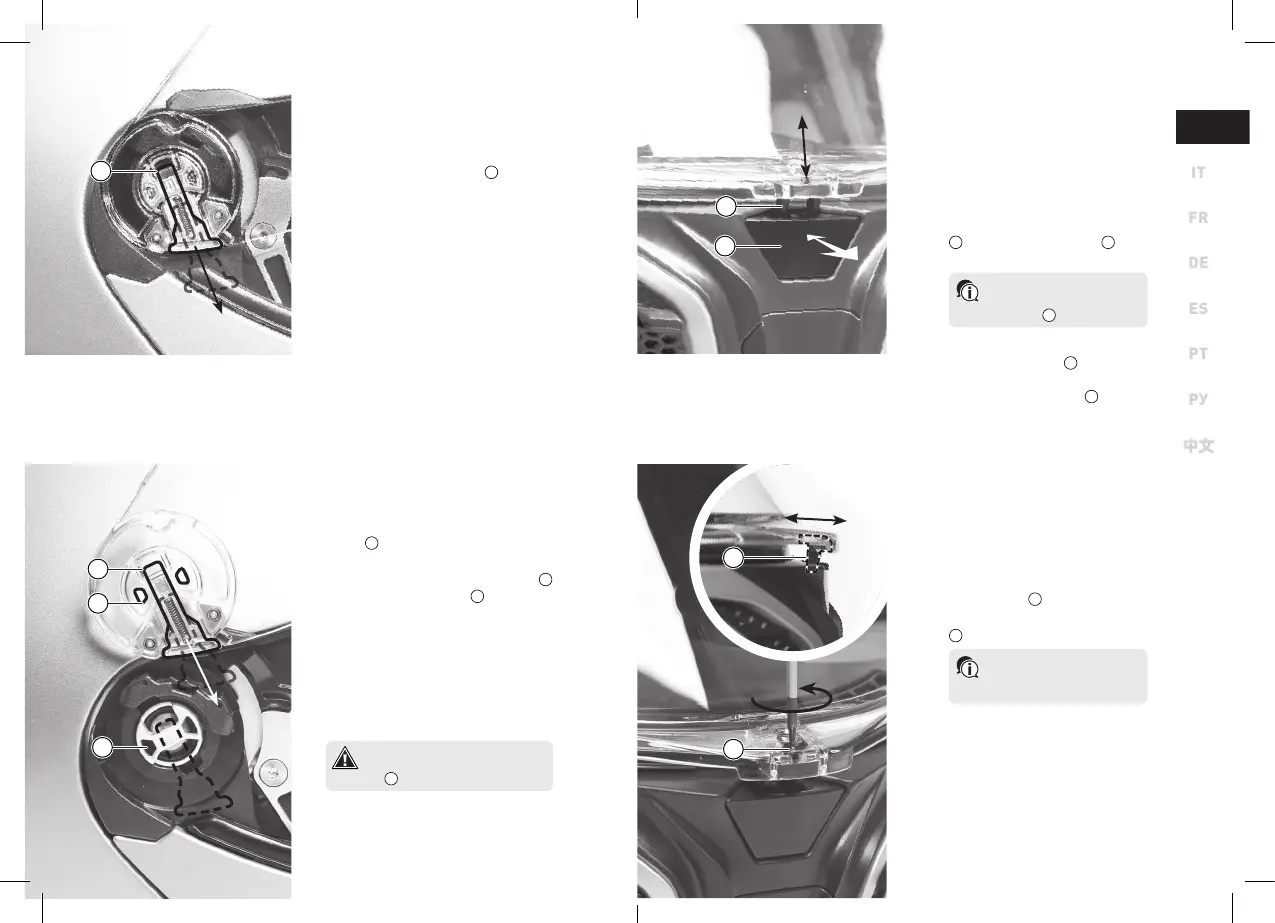

5.6 CLOSURE ADJUSTMENT

It is possible to adjust the position of the hook-

ing cog, thus changing the pressure thereby

required to the button to open the visor.

Prerequisite: the visor is installed and open, and the

helmet is resting on a flat surface. Use a Torx

®

T7

screwdriver.

• Loosen the screw

1

.

• Adjust the position of the engagement catch

2

as desired.

The farther back the catch is posi-

tioned, the more pressure is required

on the button to open the visor.

• Tighten the screw.

› Make sure that the visor closes securely.

5.5 MICRO-OPENING

In this position the visor is firmly closed pro-

viding maximum safety, but it creates a gap

of about 5mm to allow a moderate flow of air

inside the helmet.

Prerequisite: the visor is open.

› Lower the visor until the engagement catch

1

engages the opening button

2

to the

first click.

If necessary, facilitate this en-

gagement by pressing the visor

open button

2

lightly.

Prerequisite: the visor is closed.

› Press the opening button

2

and, in a single

movement, move the visor slightly upwards

until the engagement catch

1

locks the

visor to the first click.

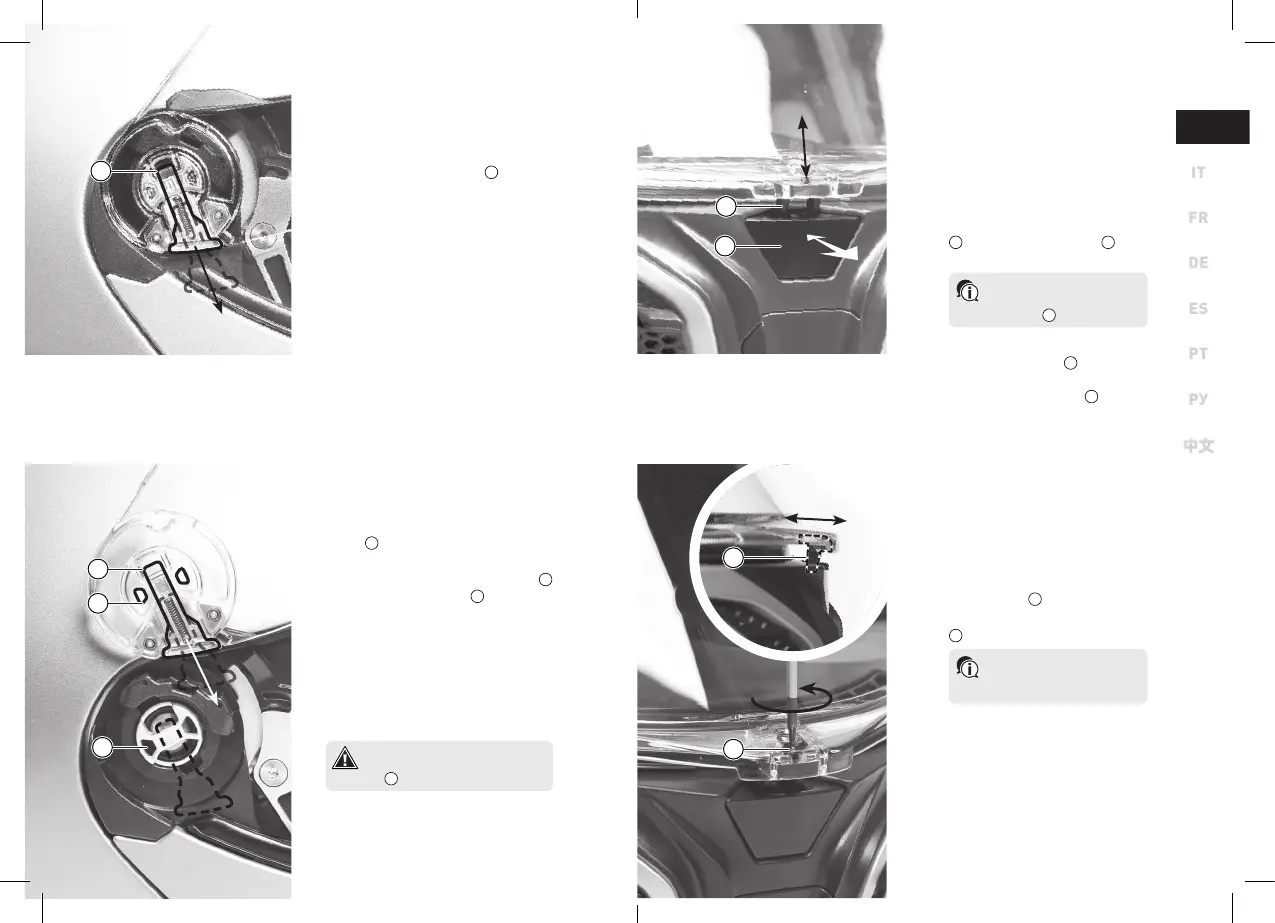

5.3 REMOVAL

Prerequisite: the visor is fully open. Start the operation

on the right-side visor mechanism.

• Pull down the spring slider

1

with a fin-

gernail, then detach the visor from the

mechanism.

› Repeat the operation on the visor mechanism

on the left-side visor mechanism.

5.4 INSTALLATION

Prerequisite: begin the operation on the right-side visor

mechanism.

• Grasp the visor and pull down the spring slid-

er

1

with a fingernail.

• Place the visor on the associated mecha-

nism, so that the two engagement tabs

2

are seated into their slots

3

.

• Release the spring slider.

• Repeat the above operations on the left-side

visor mechanism.

› Visor installed. Rotate it, making sure it

is securely attached and the movement is

smooth.

2

1

3

1

1

2

1

2

Opening / closing the chinguard without the vi-

sor fitted can cause the come out of the mecha-

nism

3

from its sliding seat.

Loading...

Loading...