7

ICE CFA1120A-3360A & CGA3180A I&O Manual 03/2021 Rev.5

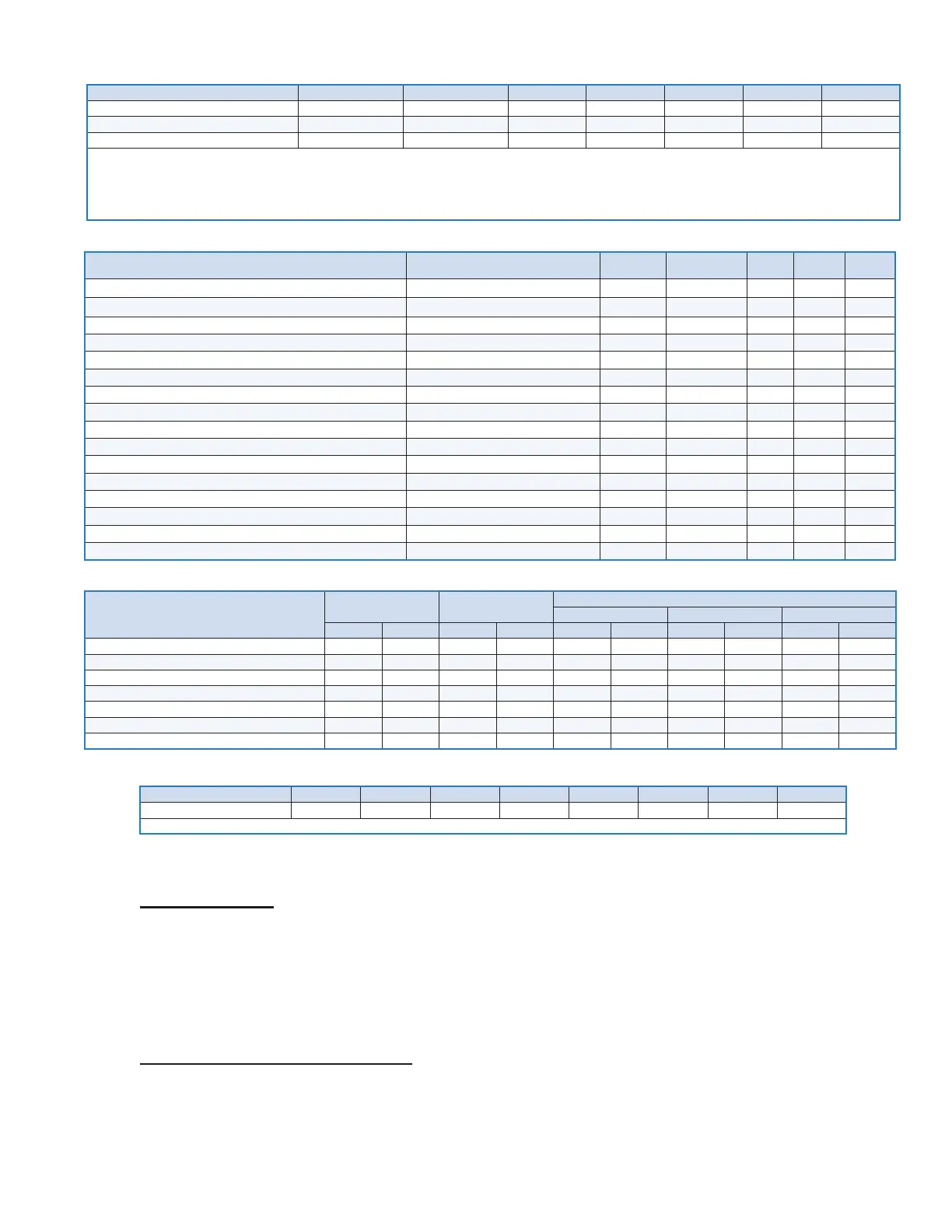

Model Number CFA1120 CFA1150/3150 CFA3180 CFA3240 CFA3300 CFA3360 CGA3180

Cooling BTUH

1

125,000 150,000 182,200 216,600 300,000 330,000 180,000

Rated Air Flow (CFM

2

) 4,500 4,500 6,500 7,400 11,900 10,200 6,000

ESP

3

@ Rated Conditions 0.30 0.35 0.35 0.40 0.45 0.55 0.35

1

Cooling rated at 95°F (35°C) outdoor and 80°F DB/67° WB (26.5°C DB/19.5°C WB) return air

2

CFM=Cubic Feet per Minute

3

ESP=External Static Pressure

Ratings are with no outside air. Performance will be affected by altitude.

Ratings are at 230 volts for 208/230 volt units (“C” models), 460 volts for “D” models, 380 volts for “E” models, 575 volts for “Z” models. Derate

performance by 17% for ACE (380v. 3ø, 50 Hz) models

Operation of units at a different voltage from that of the rating point will affect performance and air ow.

Table 1. Cooling Performance and Air Flow Ratings

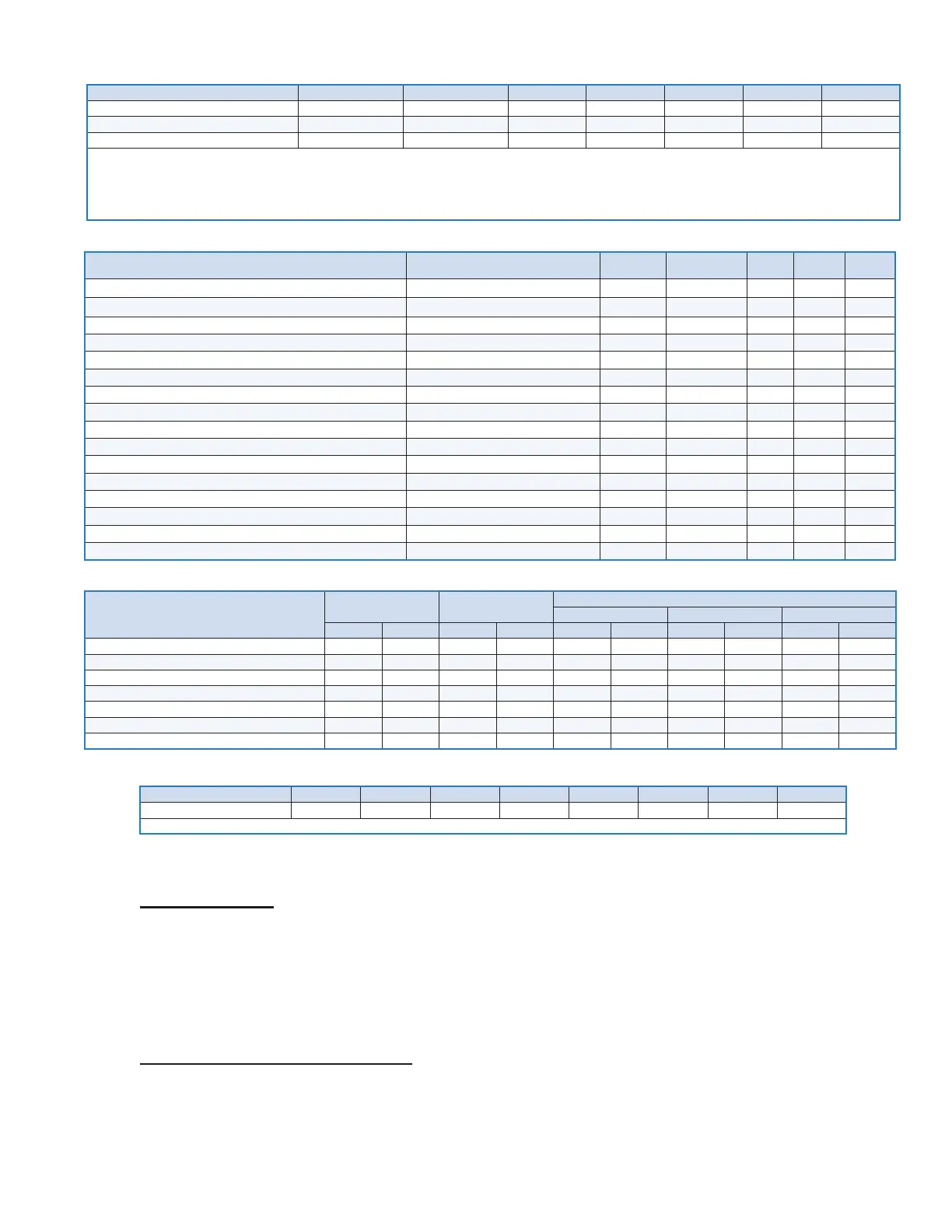

MODEL Description INCHES MILLIMETERS PART #

# OF

FILTERS

MERV

RATING

CFA1120/1150 & CFA3150 For Optional Fresh Air Hood 11 x 22 x 1 279 x 559 x 25 80119 2 N/A

CFA1120/1150 & CFA3150 Exterior Access Return Air Filter 25 x 16 x 2 635 x 406 x 51 80137 3 8

CFA1120/1150 & CFA3150 Interior Access Return Air Filter 15 x 20 x 2 381 x 508 x 51 92365 3 8

CFA1120/1150 & CFA3150 w/Economizer Fresh Air Hood Pre-lters 26 x 12 x 1” 660 x 305 x 25 92526 2 N/A

CFA1120/1150 & CFA3150

Reverse Flow w/Economizer

Economizer Pre-lter 9

1

/

4

x 37 x

3

/

8

235 x 940 x 10 92127 1 N/A

CFA3180/3240 Exterior Access Return Air Filter 25 x 16 x 2 635 x 406 x 51 80137 4 8

CFA3180/3240 Interior Access Return Air Filter 24 x 18 x 2 610 x 457 x 51 81257 4 8

CFA3180/3240 w/Economizer Fresh Air Hood Pre-lters 26 x 12 x 1 660 x 305 x 25 92526 2 N/A

CFA3180/3240 Reverse Flow w/Economizer Fresh Air Hood Pre-lters 16 x 32 x 1 406 x 813 x 25 93187 3 N/A

CFA3300/3360 Exterior Access Return Air Filter 30 x 30 x 2 762 x 762 x 51 80156 4 8

CFA3300/3360 Interior Access Return Air Filter 24 x 18 x 2 610 x 457 x 51 81257 4 8

CGA3180 Exterior Access Return Air Filter 30 x 30 x 2 762 x 762 x 51 80156 4 8

CGA3180 Interior Access Return Air Filter 24 x 18 x 2 610 x 457 x 51 81257 4 8

CGA3180

For Optional Fresh Air Hood, #K/04657

26 x 12 x 1 660 x 305 x 25 92526 2 N/A

CGA3180 Reverse Flow Exterior Access Return Air Filter 30 x 30 x 2 762 x 762 x 51 80156 4 8

CGA3180 Reverse Flow Interior Access Return Air Filter 24 x 18 x 2 610 x 457 x 51 81257 4 8

Table 2. Filter Sizes/Part Numbers

MODEL

Unit Weight Shipping Weight

Shipping Dimensions

Height Width Depth

LBS KG LBS KG Inches MM Inches MM Inches MM

CFA1120 1,160 527.3 1,285 584.1 98 2,489 56 1,422 48 1,219

CFA1150 & CFA3150 1,166 530 1,291 586.8 98 2,489 56 1,422 48 1,219

CFA3180 2,307 1,046 2,420 1,098 98 2,489 76 1,930 51 1,295

CFA3240 2,523 1,144 2,636 1,196 98 2,489 76 1,930 51 1,295

CFA3300 2,625 1,193 2,750 1,250 108 2,743 72 1,829 72 1,829

CFA3360 3,210 1,456 3,335 1,513 108 2,743 72 1,829 72 1,829

CGA3180 3,210 1,456 3,335 1,513 108 2,743 72 1,829 72 1,829

Table 3. Shipping Weights & Dimensions

Model CFA1120 CFA1150 CFA3150 CFA3180 CFA3240 CFA3300 CFA3360 CGA3180

Refrigerant Charge (Oz) 367 367 152

1

240

1

264.5

1

432

1

416

1

320

1

1

Per circuit on dual compressor models

Table 4. Refrigerant Charge (R410A, Ounces)

1.5 General Operation

Hot Gas By-Pass

Normally used in specialty applications (i.e Magnetic Resonance Imaging (MRI) buildings) to prevent

magnetic voltage disturbance caused by cycling. This technology is applied in this product to extend

the operation envelope for the compressor to 20º F (-6.6ºC). Combined with a condenser low ambient

Fan Cycle feature, compressor operation can be extended to 0º F (-17.8ºC). During Hot Gas operation

mode, system performance will be reduced. If product operation is in mild outdoor ambient conditions,

the installed shut-off ball valve may be closed, thus disabling the Hot Gas By-Pass feature.

Refrigerant Cycle (Cooling Mode)

The air conditioners use R-410A refrigerant in a conventional vapor-compression refrigeration cycle to

transfer heat from air in an enclosed space to the outside. A motorized impeller assembly blows indoor

air across the evaporator. Cold liquid refrigerant passing through the evaporator is boiled into gas by

heat removed from the air. The warmed refrigerant gas enters the compressor where its temperature and

Loading...

Loading...