Medium-Pressure Stub Pump

SER 9668

Alemite Corporation 7 Revision (1-97)

Pump Tube and Rod

11. Install and seat Nylon Piston (

16

) [openings upward]

onto the bottom of Rod (

15

).

12. Install Ball (

17

) into the Rod.

IMPORTANT: Do not tighten the Valve Seat

more than 1/4-turn once it contacts the Ny-

lon Piston. Distortion of the Nylon Piston

can occur which causes excessive drag on

the Tube.

13. Screw Valve Seat (

18

) [with Loctite 222] into the Rod.

See

Figure 2.

• Follow the thread sealant manufacturer’s

recommendations.

CAUTION

Install the Rod into the Body with a twisting

motion. Use care not to damage the Seals.

14. Install the Rod assembly into the bottom of the Body.

• Position the Nylon Piston flush with the bottom of

the Body.

15. Install Back-Up Ring (

20

) [concave upward] onto

Tube (

21

).

16. Install O-Ring (

19

) on top of the Back-Up Ring.

17. Screw and seat the Tube assembly into the Body.

• Make sure both Rings are not visible.

18. Slide Bung Adapter (

22

) onto the Tube.

19. Screw the Foot Valve assembly into the Tube.

• Tighten the Foot Valve assembly securely to the

Tube and the Tube to the Body.

Assembly

NOTE

: Prior to assembly, certain compo-

nents require lubrication. Refer to

Table 3

for details.

Foot Valve

NOTE

: Refer to

Figure 4

for a section view

of the pump tube assembly.

1. Install O-Ring (

26

) onto Foot Valve (

27

).

2. Install Ball (

25

), Spring (

24

) [small diameter first], and

Washer (

23

) into the Foot Valve.

3. Install Pin (

28

) into the Foot Valve.

• Make sure the Pin retains the Washer properly and is

flush with the Foot Valve.

Pump Tube Body

4. Install O-Ring (

5

) onto the upper groove of Body (

6

).

5. Install and seat Seal (

11

) [heel end first] into the

bottom of the Body.

6. Install and seat Bearing (

12

) [small diameter first] into

the Body.

7. Install and seat Seal (

13

) [heel end first] into the Body.

CAUTION

Make sure the hole in the Spacer aligns with the

hole in the Body. Damage to components can

occur.

8. Install Spacer (

14

) [small diameter first] into the Body.

9. Install O-Ring (

7

) onto Adapter (

8

).

10. Screw the Adapter into the Body.

• Tighten the Adapter securely.

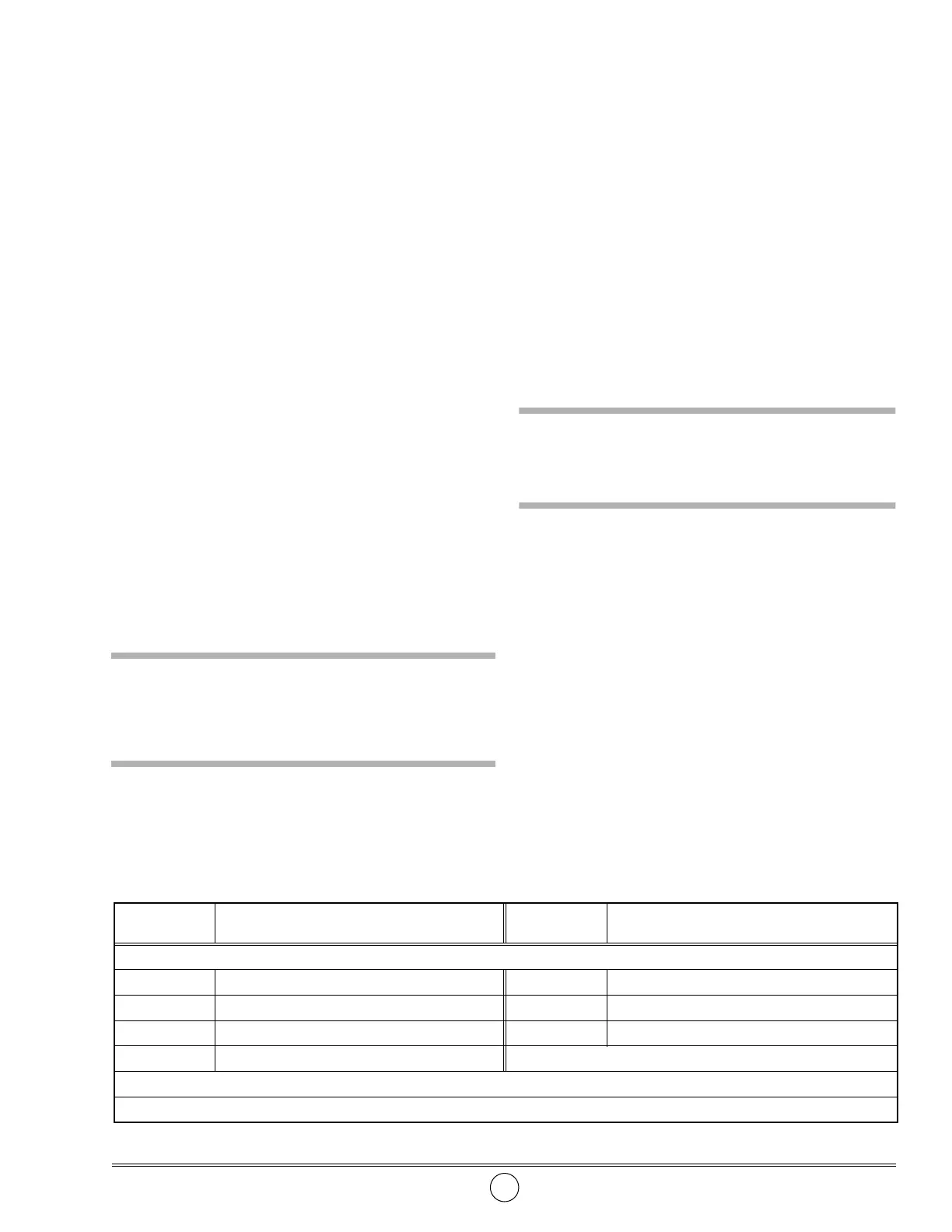

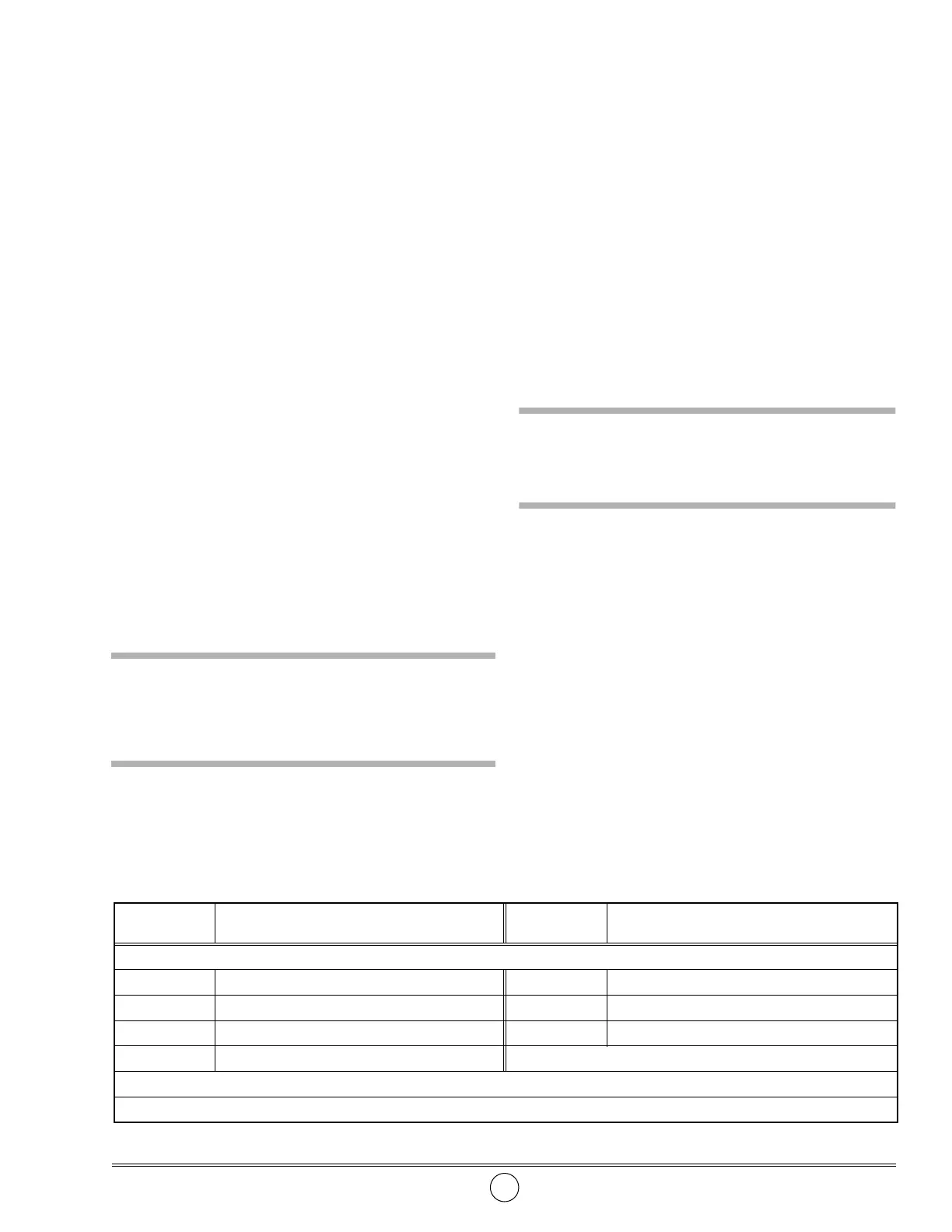

Item No.

on

Figure 2

Description

Item No.

on

Figure 2

Description

Clean Oil

4 O-Ring, 2-5/8 " ID x 3 " OD 13 Seal, 1-5/16 " ID x 1-11/16 " OD

5 O-Ring, 2-3/4 " ID x 3 " OD 19 O-Ring, 1-7/8 " ID x 2 " OD

7 O-Ring, 3/4 " ID x 15/16 " OD 26 O-Ring, 1-11/16 " ID x 1-7/8 " OD

11 Seal, 1-5/16 " ID x 1-9/16 " OD

Magnalube-G Teflon Grease

Coat the Inside Diameter of the Air Motor Assembly

Table 3

Lubricated Components

1-800-548-1191-http://www.partdeal.com-info@partdeal.com

Loading...

Loading...