4 Installation

To ensure optimum operation it is important that any pump unit is installed correctly. When designing a pumping system the

following should be taken into consideration.

Coupling alignment:

Before the pump unit is installed is it important to ensure that the mounting surface is flat to avoid distortion of the baseplate,

which may cause pump/motor shaft misalignment and pump/motor unit damage. Once the baseplate has been secured, the

pump shaft to motor shaft coupling alignment should be checked and adjusted as necessary. This is achieved by checking

the maximum angular and parallel misalignment for the couplings as stated below. Shaft alignment that is outside the stated

tolerances can be corrected by applying shims under the motor or pump foot, or, by moving the pump or drive sideways on

the baseplate. All bolts that have been loosened should be re-tightened to the stated torque figure.

The following dimensions and tolerances apply to standard supply couplings only.

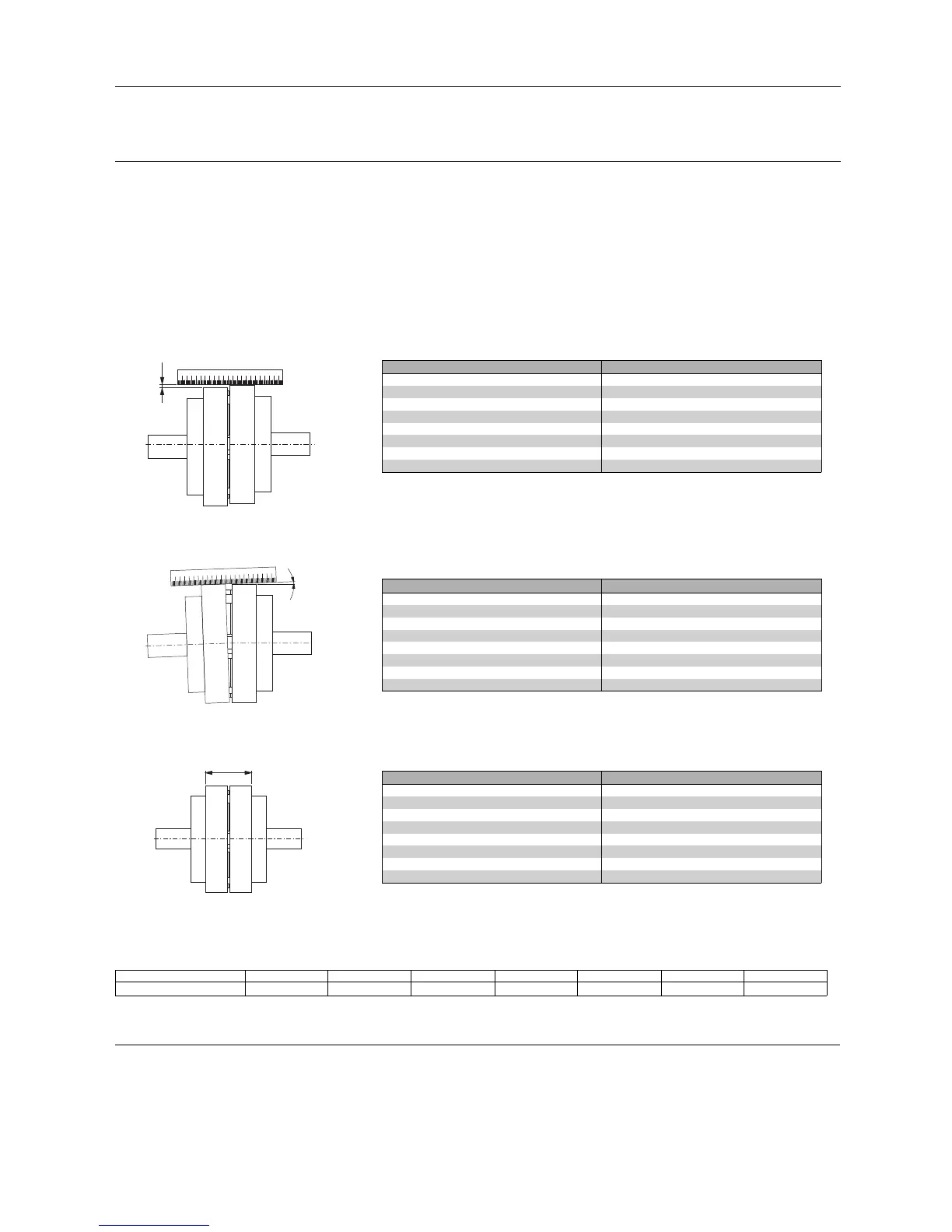

Parallel misalignment

Measure 4 positions at 90° around coupling

Coupling size

Dimension A Maximum

70 0.3 mm

90 0.3 mm

110 0.3 mm

130 0.4 mm

150 0.4 mm

180 0.4 mm

230 0.5 mm

280 0.5 mm

TD 246-090

A

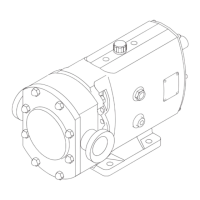

Angular misalignment

Measure 4 positions at 90° around coupling

Coupling size

Dimension B Maximum

70 1°

90 1°

110 1°

130 1°

150 1°

180 1°

230 1°

280 1°

TD 246-089

B

o

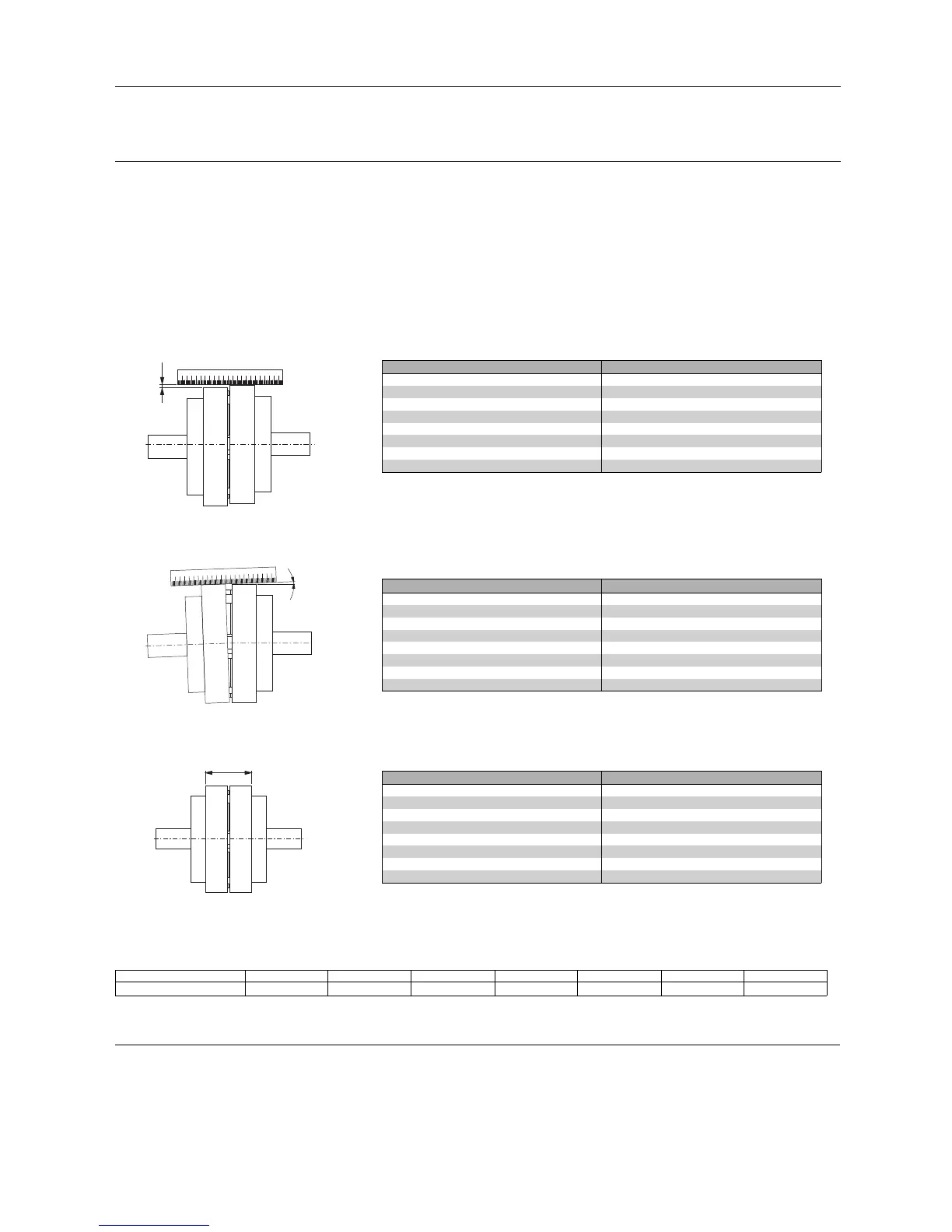

Assembled length

Coupling size

Dimension L ± 1.0mm

70 25

90 30.5

110

45

130 53

150 60

180 73

230 85.5

280 105.5

TD 246-088

L

Recommended bolt torques.

Thread Diameter M6 M8 M10 M12 M16 M20 M24

Torque (N m)

6

15

30 50 120 250 200

1

2

Loading...

Loading...