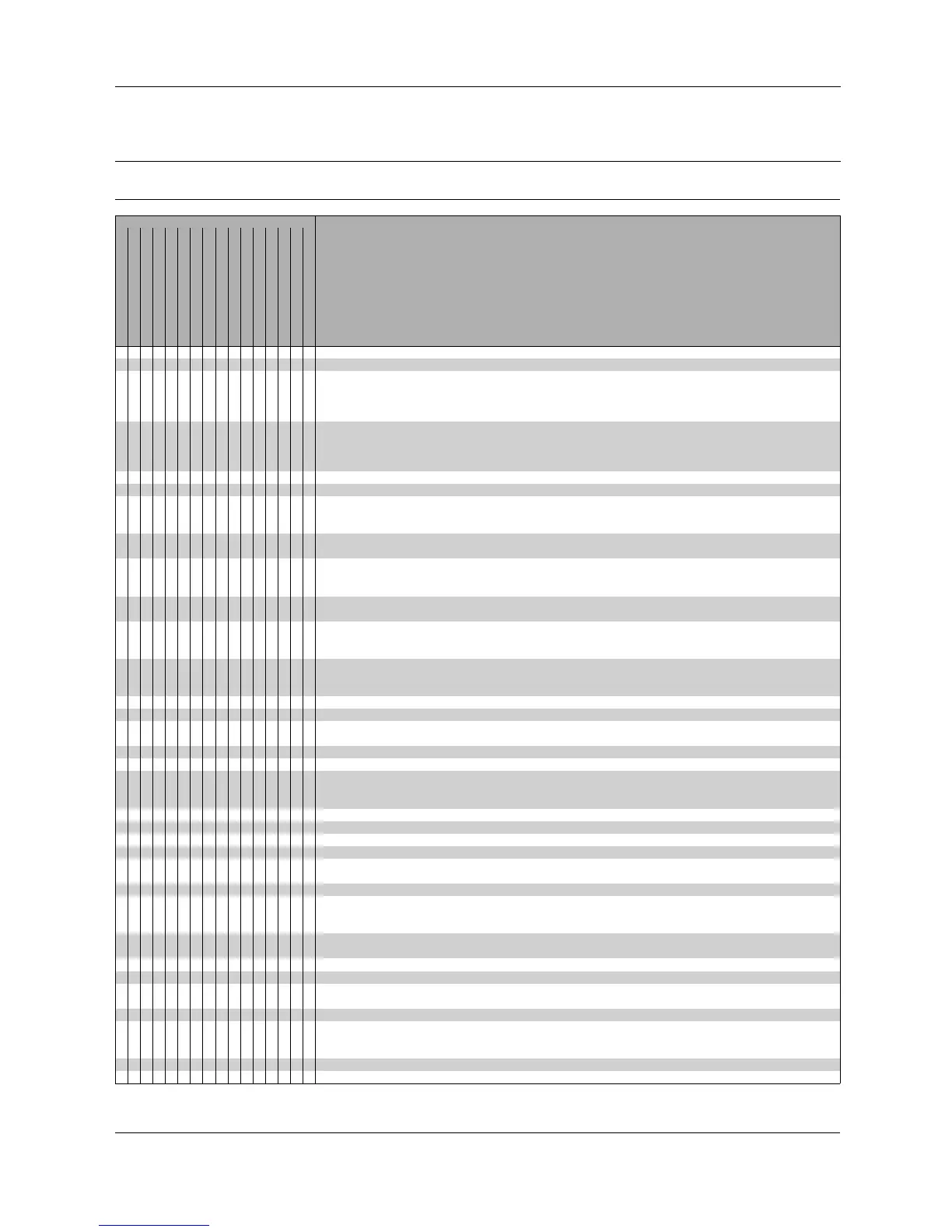

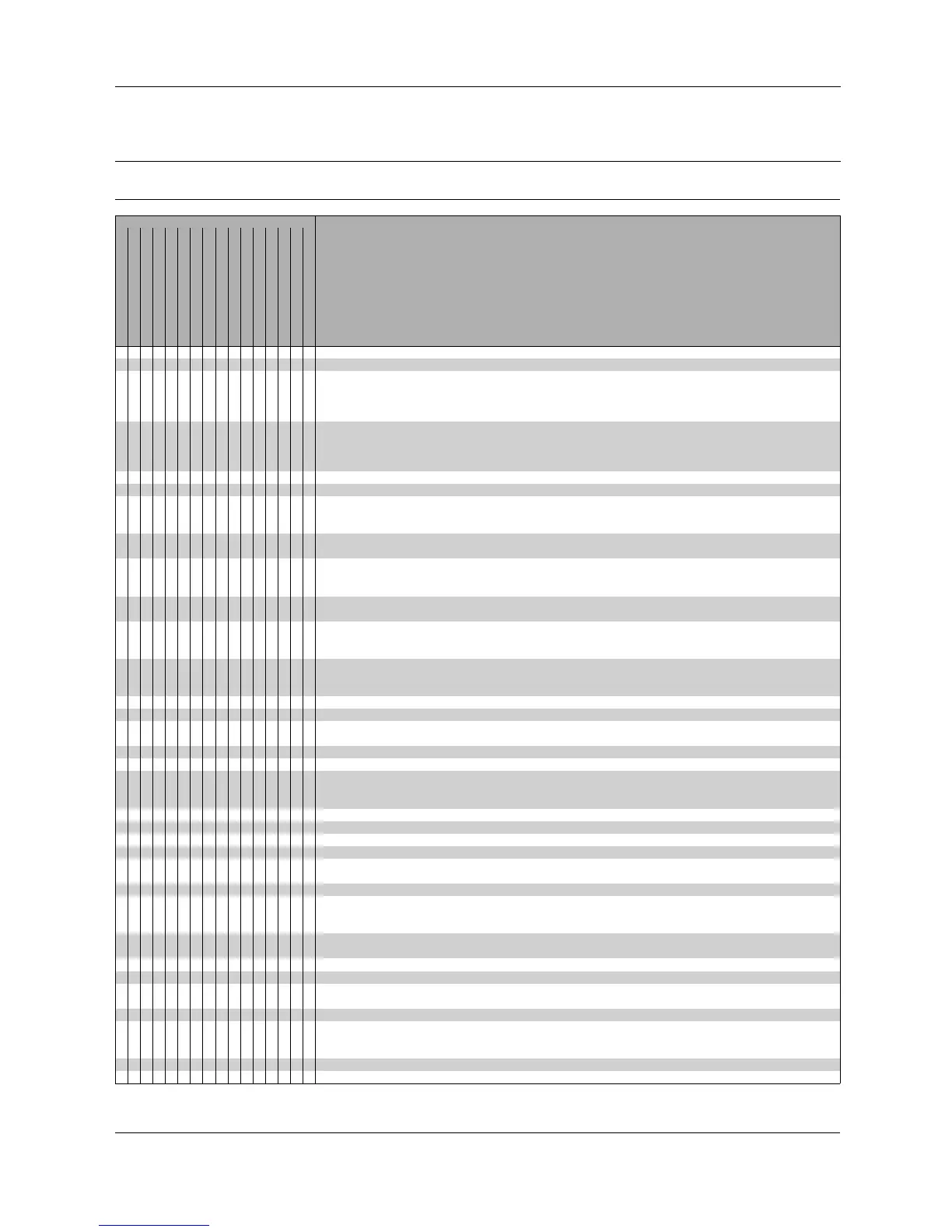

5 Maintenance

5.8 Troubleshooting

Problem

No flow

Under capacity

Irregular discharge

Low discharge pressure

Pump will not prime

Prime lost after starting

Pump stalls when starting

Pump overheats

Motor overheats

Excessive power absorbed

Noise and vibration

Pump element wear

Syphoning

Seizure

Mechanical seal leakage

Mechanical seal leakage

Probable Causes Solutions

√√

Incorrect direction of rotation. Reverse motor.

√

Pump not primed. Expel gas from suction line and pumping chamber and introduce fluid.

Increase suction line diameter.

Increase suction head.

Simplify suction line configuration and reduce length.

√√√√ √ √

Insufficient NPSH available.

Reduce pump speed.

Increase suction line diameter.

Increase suction head.

Simplify suction line configuration and reduce length.

√√√ √ √

Fluid vaporising in suction line.

Reduce pump speed.

√√√ √√ √

Air entering suction line.

Remake pipework joints.

√√ √√ √

Strainer or filter blocked.

Service fittings.

Increase fluid temperature.

Decrease pump speed.

√ √√√√√√ √

Fluid viscosity above rated figure.

Check seal face viscosity limitations.

Decrease fluid temperature.

√√ √

Fluid viscosity below rated figure.

Increase pump speed.

Cool the pump casing.

Reduce fluid temperature.

√√√√√

Fluid temp. above rated figure.

Check seal face and elastomer temp. limitations.

Heat the pump casing.

√√√

Fluid temp. below rated figure.

Increase fluid temperature.

Clean the system.

Fit strainer to suction line.

√√ √√

Unexpected solids in fluid.

If solids cannot be eliminated, consider fitting double mechanical seals.

Check for obstructions i.e. closed valve.

Service system and change to prevent problem recurring.

√√√ √√√√√√√ √√√

Discharge pressure above rated figure

Simplify discharge line to decrease pressure.

√√√ √

Gland over-tightened Slacken and re-adjust gland packing.

√√√√√

Gland under-tightened Adjust gland packing.

Increase flush flow rate.

√√

Seal flushing inadequate.

Check that flush fluid flows freely into seal area.

√ √√√

Pump speed above rated figure. Decrease pump speed.

√√

Pump speed below rated figure. Increase pump speed.

Check alignment of pipes.

Fit flexible pipes or expansion fittings.

√ √√√√√ √

Pump casing strained by pipework.

Support pipework.

√√√√

Flexible coupling misaligned. Check alignment and adjust mountings accordingly.

√√√√√ √

Insecure pump driver mountings. Fit lock washers to slack fasteners and re-tighten.

√√√√√ √√√

Shaft bearing wear or failure. Refer to pump maker for advice and replacement parts.

√√√√√ √

Insufficient gearcase lubrication.

Refer to pump maker’s instructions.

Check rated and duty pressures.

√√ √√√√√ √

Metal to metal contact of pumping element.

Refer to pump maker.

√√ √

Worn pumping element. Fit new components.

Check pressure setting and re-adjust if necessary.

Examine and clean seating surfaces.

√√ √

Rotorcase cover relief valve leakage.

Replace worn parts.

Check for wear on sealing surfaces, guides etc.

√√

Rotorcase cover relief valve - chatter.

Replace if necessary.

√√

Rotorcase cover relief valve incorrectly set. Re-adjust spring compression - valve should lift approx. 10% above duty pressure.

√√

Suction lift too high. Lower pump or raise liquid level.

Fluid pumped not compatible with

√√

materials used.

Use optional materials.

√

No barrier in system to prevent flow passing. Ensure discharge pipework higher than suction tank.

Ensure system operation prevents this.

Fit single or double flushed mechanical seals.

√√

Pump allowed to run dry.

Fit flushed packed gland.

√√

Faulty motor. Check and replace motor bearings.

√

Pumping element missing Fit pumping element.

3

6

Loading...

Loading...