5 Maintenance

This page is not applicable for ATEX applications.

For ATEX application see ATEX addendum

5.5 Primary seals removal and fitting

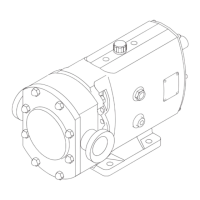

5.5.1 R90 Single mechanical seal

Mechanical seals are fragile. Take extreme care when handling.

Clean components before fitting, checking there is no damage

to sealing faces. New elastomeric parts should be fitted during

assembly.

Rotor

Shaft

Setting dimension

Setting Dimension

Pump

mm

in

Item

Description

SRU1 33.6 1.32

71

Stationary seal ring O-ring

SRU2

35.6 1.40 72

Stationary seal ring

SRU3 38.1 1.50 73

Rotary seal ring

SRU4

39.6 1.56

SRU5

47.6 1.87

SRU6

50.7 2.00

74

Rotary seal assembly comprising of rotary seal ring,

washer (98), wave spring (99), drive ring (100) and

grub screw (78)

Seal removal

1. Remove rotorcase cover, rotors and rotorcase.

2. Extract the stationary seal ring (72) and O-ring (71) from the rotorcase.

3. Loosen the grub screws (78).

4. Remove the rotary seal assembly (74) from the shaft.

5. Remove abutment spacer if fitted.

6. Extract the rotary seal O-ring (73) from the rotary seal assembly.

Seal fitting

1. Mark the shaft to indicate the seal setting length, shown in table above.

2. Lightly lubricate O-rings (71) with appropriate grease and fit to stationary seals (72).

3. Press the stationary seal rings into the rotorcase seal bores by aligning cut outs with the anti-rotation pins.

4. Wipe clean the stationary seal faces with solvent.

5. Lightly lubricate shafts and if fitted, replace seal abutment spacers pressing them over shafts against the shaft shoulder.

6. Lightly lubricate O-rings (73) and fit to rotary seal ring (74).

7. Adjust rotary seal assembly grub screws (78) to ensure that screws do not foul on shafts when fitted.

8. Slide rotary seal assembly on to the shafts until aligned with the setting dimension mark.

9. Tighten the grub screws to the recommended torque figure in table 6.1.3.

10. Wipe clean the rotary sealing faces with solvent.

11. Refit the rotorcase, rotors and front cover.

27

Loading...

Loading...