5 Maintenance

5.7 Heating/Cooling devices

The SRU pumps have the option of being fitted with heating/cooling devices.

These are primarily used for heating the pumphead so as to maintain the pumped media viscosity and reduce risk of any

crystallisation/solidification.

They may also be used for cooling purposes.

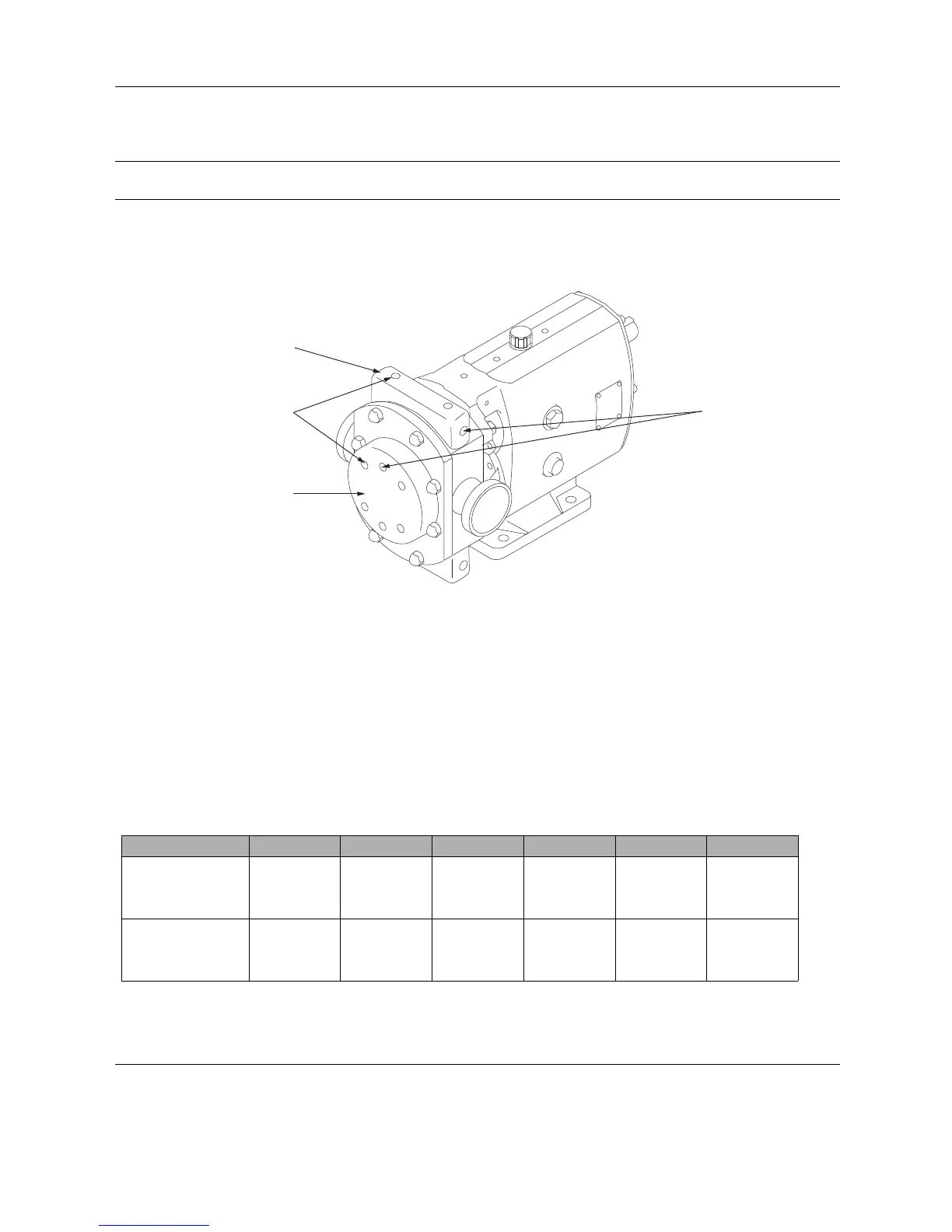

Saddle

Connections

Screw

for steam,

hot/cold fluid

Jacket

TD 243-087

Jackets can be fitted to the rotorcase cover and/or saddles can be fitted to the rotorcase.

The maximum pressure and temperature of heating/cooling fluid is 3.5 bar (50 psi) and 150°C (302°F) respectively.

Heating/cooling jackets and saddles should be in operation

approximately 15 minutes prior to pump start up and remain in

operation 15 minutes after pump shut down.

Assembly

1. Clean faces where sealant is to be applied

2. Apply Loctite 5970 silicone sealant or equivalent to face of heating jacket/saddle allow to dry for approx. 5-10 minutes.

3. Locate cap screws in jacket/saddle, and align screws with tapped holes in rotorcase/front cover and tighten evenly.

4. Allow instant gasket to cure fully before operation

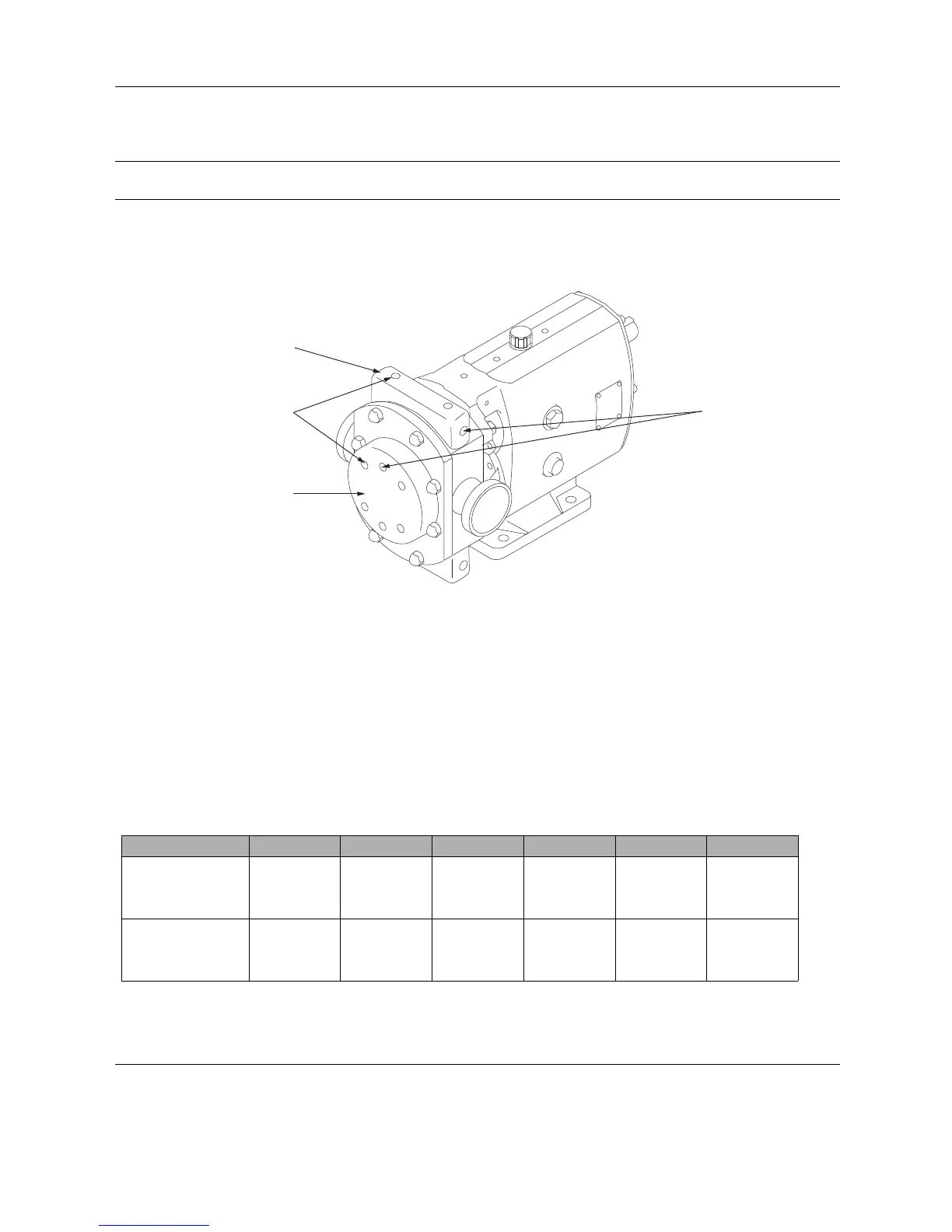

SRU1 SRU2 SRU3 SRU4 SRU5 SRU6

Screw

Saddle (size/torque)

M4/2Nm M6/8 Nm M6/8 Nm M6/18 Nm M6/35 Nm M6/35 Nm

Jacket (size/torque)

M8/8 Nm M8/8 Nm M10/8 Nm M8/18 Nm M10/18 Nm M8/18 Nm

Flush connection

Saddle (BSPT)

1/8” 1/4” 1/4” 1/4” 1/4” 1/4”

Jacket (BSPT)

1/4” 1/4” 1/4” 1/4” 1/4” 1/4”

All flush connections are Female

35

Loading...

Loading...