5 Maintenance

This page is not applicable for ATEX applications.

For ATEX application see ATEX addendum

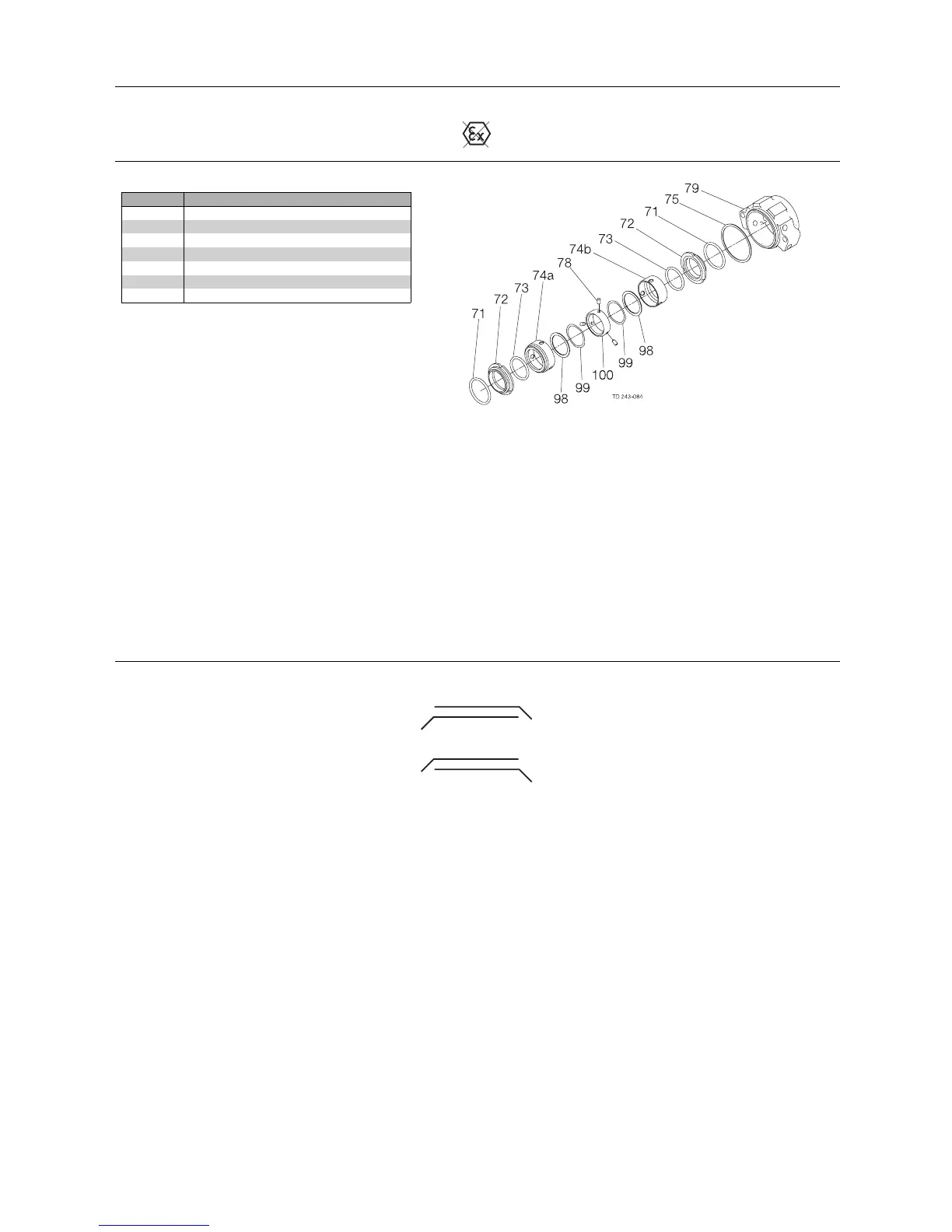

5.5.3 R90 Double flushed mechanical seal

Item

Description

71

Stationary seal ring O-ring

72

Stationary seal ring

73

Rotary seal ring O-ring

74a

Rotary seal ring assembly - inboard

74b

Rotary seal ring assembly - outboard

75

Seal housing O-ring

79

Seal housing

The Rotary Seal Assembly Inboard (74A) comprises of rotary seal ring,

washer (98), wave spring (99) and drive ring (100). The Rotary Seal

Assembly Outboard (74B) comprises of rotary seal ring, grub screw

(78), washer (98) and wave spring (99).

Seal removal:

1. Ensure the flush media is turned off and disconnect the flushing pipework.

2. Remove rotorcase cover and rotors.

3. Turn the drive shaft until the drive ring grub screws (78) are visible through the flushing connections.

4. Loosen the grub screws.

5. Remove the rotorcase.

6. Remove seal housings (79) complete with rotary seal assemblies (74A and 74B) and outboard stationary seals.

7. Extract the seal housing O-ring (75), stationary seal ring (72) and ‘o’ ring (71) from the rotorcase.

Seal fitting:

Ensure seal orientation is correct.

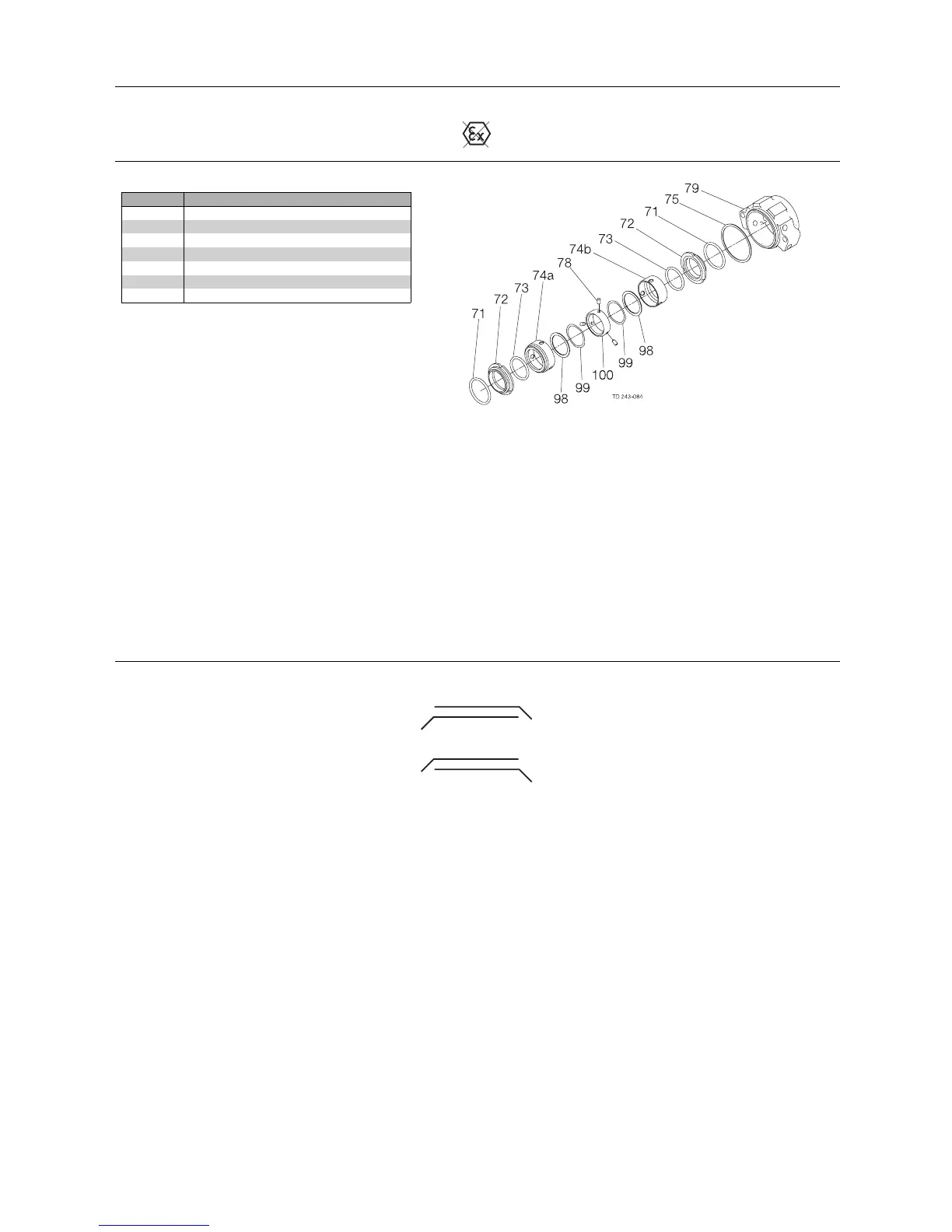

Outboard

Inboard

Series 1, the outboard seal fits over the

inboard seal.

Inboard

Outboard

Series 2-6, the inboard seal fits over the

outboard seal.

1. Lightly lubricate O-rings (71 and 73) with ap

propriate grease and fit to rotary seal assemblies and stationary seal rings

(74A, 74B and 72).

2. Fit stationary seals into the rotorca

se bores and seal housings (79).

3. Fit O-ring (75) into the

rotorcase bores.

4. Wipe clean the sealin

g faces with solvent.

5. Locate rotary seal

assemblies and fit the seal housings to the rotorcase ensuring that the grub screws (78) are accessible

so they can be tig

htened.

6. Refit the roto

rcase.

7. Turn the dri

ve shaft until the grub screws are visible through the flushing connections.

8. Tighten t

hegrubscrewstotherecommendedtorquefigurein.

9. Refit t

he rotors and rotorcase cover.

29

Loading...

Loading...