14 MicroLogix™ 1500 Programmable Controller Base Units

Publication 1764-IN001A-ML-P

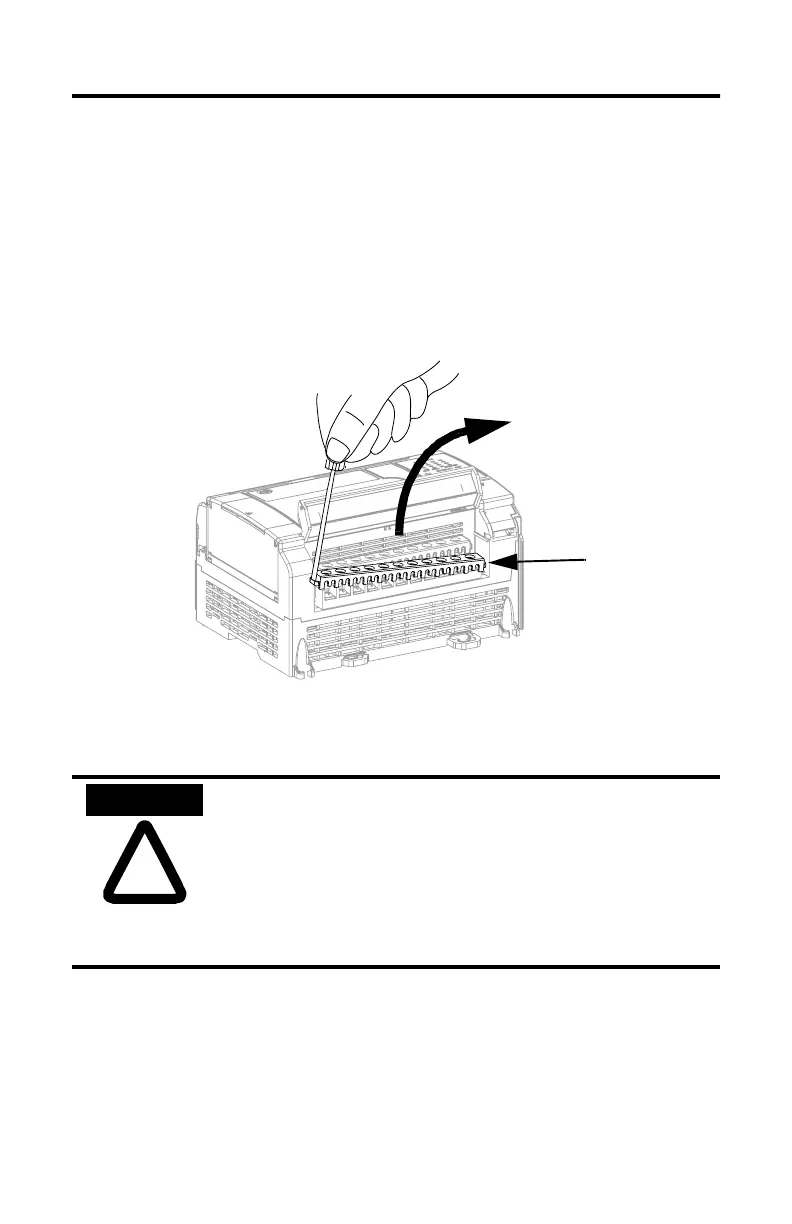

Spade Lug Recommendation

The diameter of the terminal screw head is 5.5 mm (0.220 in.). The input and

output terminals of the MicroLogix 1500 base unit are designed for the following

spade lugs. The terminals will accept a 6.35mm (0.25 in.) wide spade (standard

for #6 screw for up to 14AWG) or a 4 mm (metric #4) fork terminal.

When using spade lugs, use a small, flat-blade screwdriver to pry the finger-safe

cover from the terminal blocks, then loosen the terminal screw.

Surge Suppression

!

ATTENTION

Inductive load devices such as motor starters and solenoids

require the use of some type of surge suppression to protect the

controller output. Switching inductive loads without surge

suppression can significantly reduce the lifetime of relay

contacts or damage transistor outputs. By using suppression,

you also reduce the effects of voltage transients caused by

interrupting the current to that inductive device, and prevent

electrical noise from radiating into system wiring.

Finger-Safe Cover

Loading...

Loading...