28 Rockwell Automation Publication 750-QS001A-EN-P - March 2015

Reference Section

Power Jumper Locations

Wall/flange mount frames 1, 6, and 7 and floor mount frames 8…10 use jumper wires to complete an electrical connection

when installed.

Wall/flange mount frames 2…5 use jumper screws to complete an

electrical connection when installed.

Table 1 - Power Jumper Locations for Frames 1…10

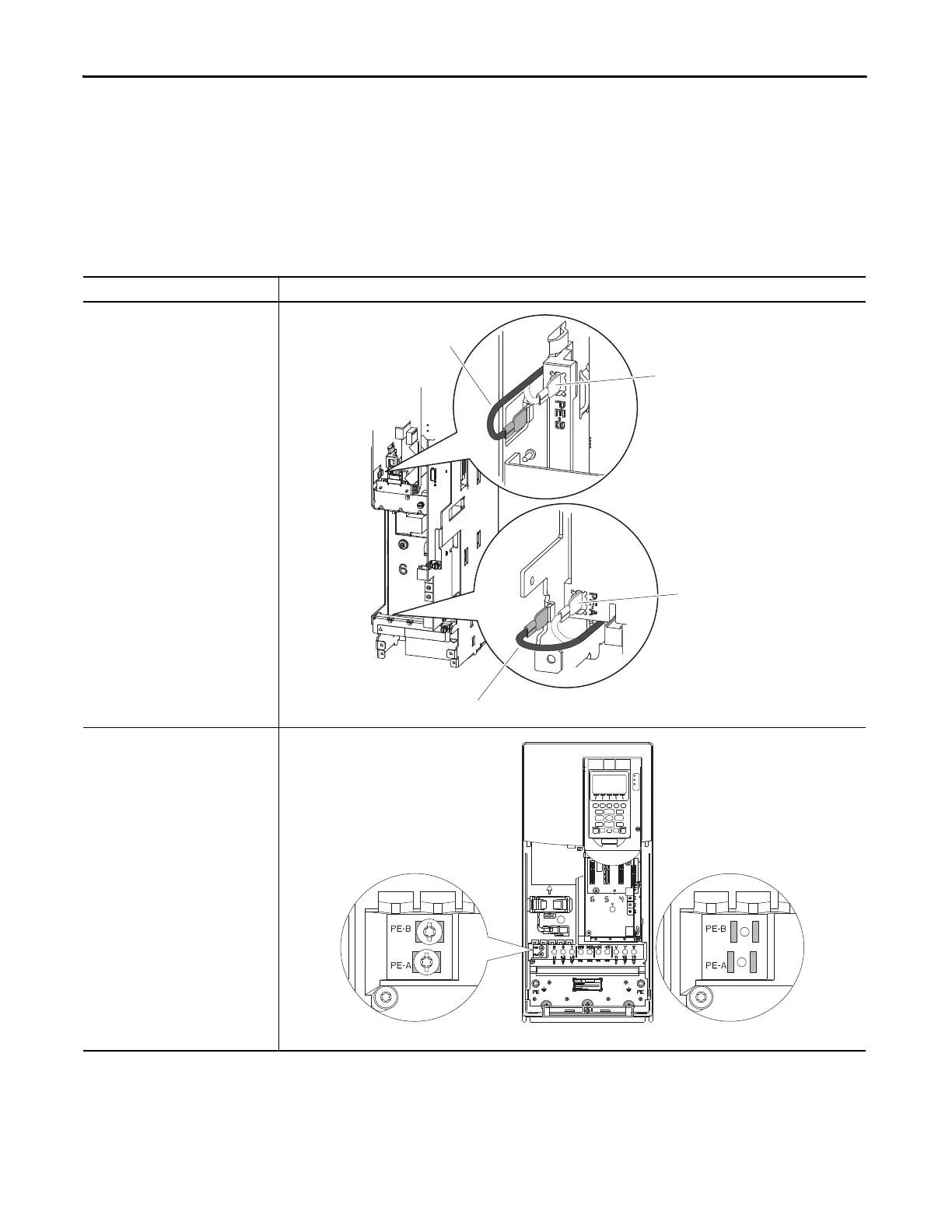

Drive Jumper Locations

Frame 1

Spade Connectors

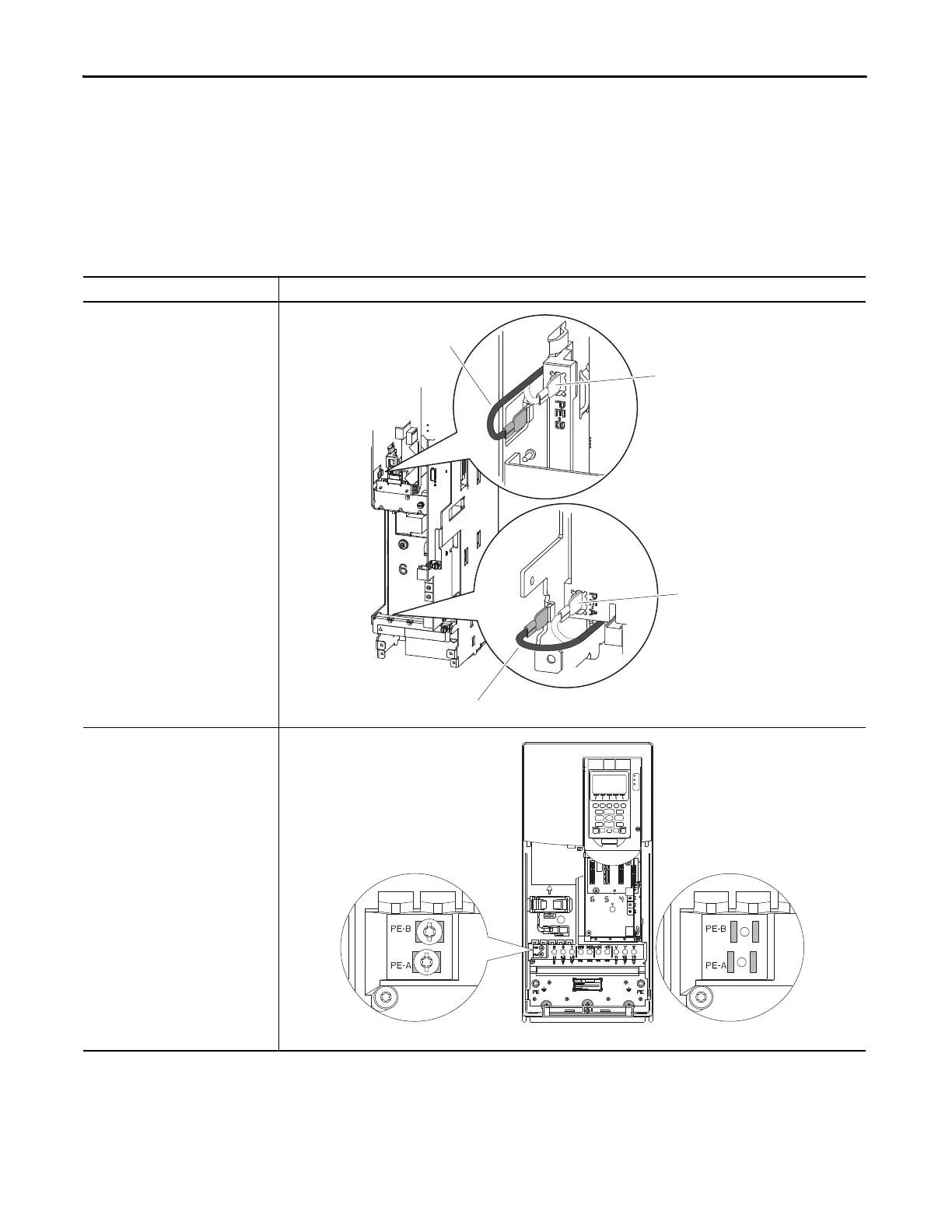

Frames 2…5

Screw Connectors

• Torque: 1.36 N•m (12.0 lb•in)

• Tool: 6.4 mm (0.25 in.) flat

or T15 Hexalobular

)

PE-A

PE-B

Disconnected

Connected

Disconnected

Connected

Disconnected

Connected

Frame 4 Shown

Loading...

Loading...