24 Rockwell Automation Publication 750-IN100B-EN-P - July 2017

Chapter 2 Receiving, Handling, and Storage

Overhead Lifting (Crane or Hoist)

All lifting equipment and lifting components (hooks, bolts, lifts, slings, chains,

and so forth) must be properly sized and rated to safely lift and hold the weight

of the equipment. Shipment weights can be found on the packing slip that is

included with each shipment. Approximate weights are listed on page 20

.

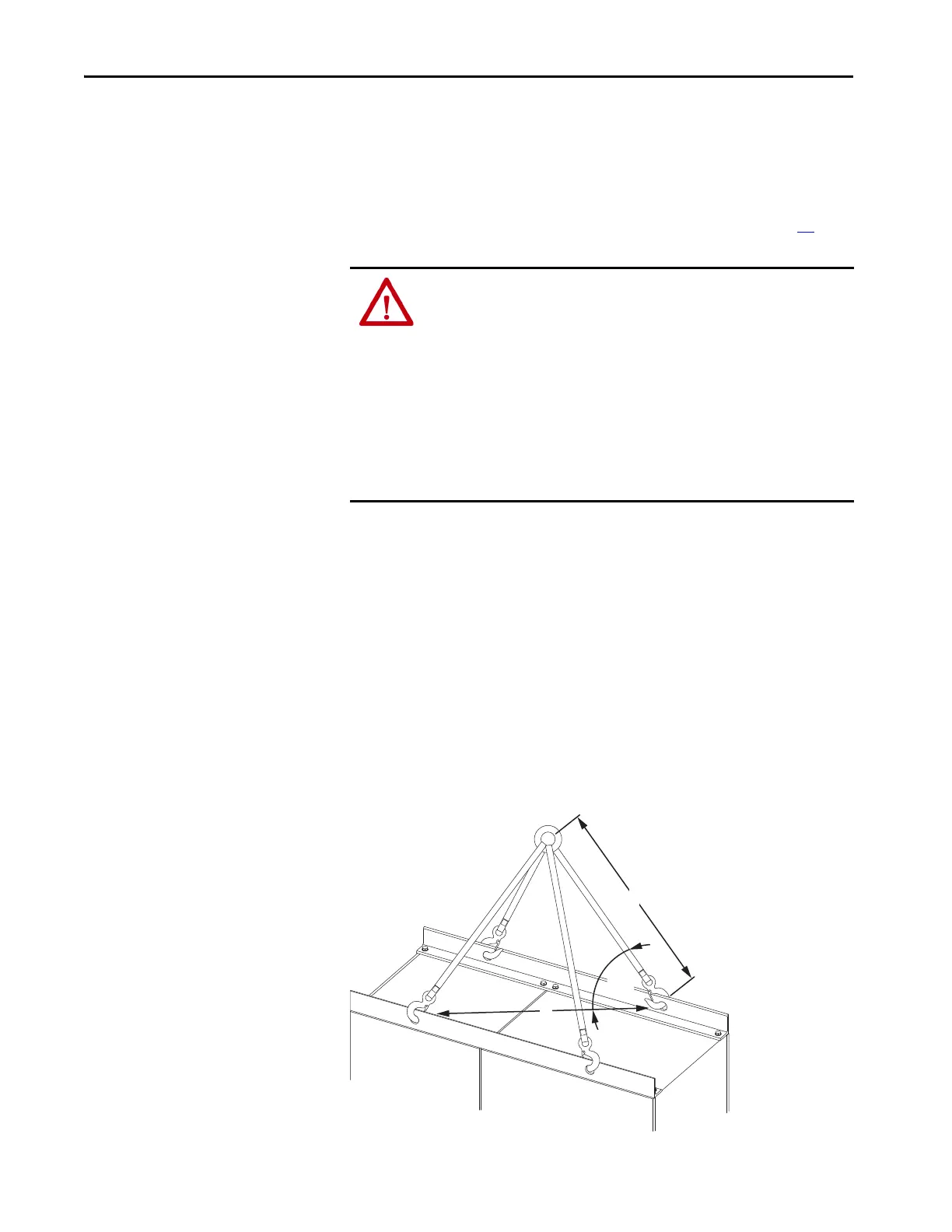

Structural angles are affixed to the top of the product enclosures.

Attach Lifting Hardware

1. Attach rigging to overhead crane, hoist, or similar lifting device.

2. Do not pass straps or cables through the lifting holes in the structural

angle. Use slings with load-rated hooks or shackles.

3. Adjust the rigging lengths to compensate for any unequal weight

distribution of the load and support the PowerFlex 755T product in an

upright position.

4. To reduce tension on the rigging and compression on the structural

angle, verify that the angle between the straps or cables and horizontal

plane is greater than 60°.

Figure 6 - Lifting Points and Rigging

ATTENTION: To guard against possible personal injury and/or equipment

damage:

• Inspect all lifting hardware for proper attachment before lifting the

equipment.

• Do not allow any part of the equipment or lifting mechanism to make

contact with electrically charged conductors or components.

• Do not subject the equipment to high rates of acceleration or deceleration

while transporting to the installation site or when lifting.

• Do not allow personnel or their limbs directly underneath the equipment

when it is being lifted and mounted.

Loading...

Loading...