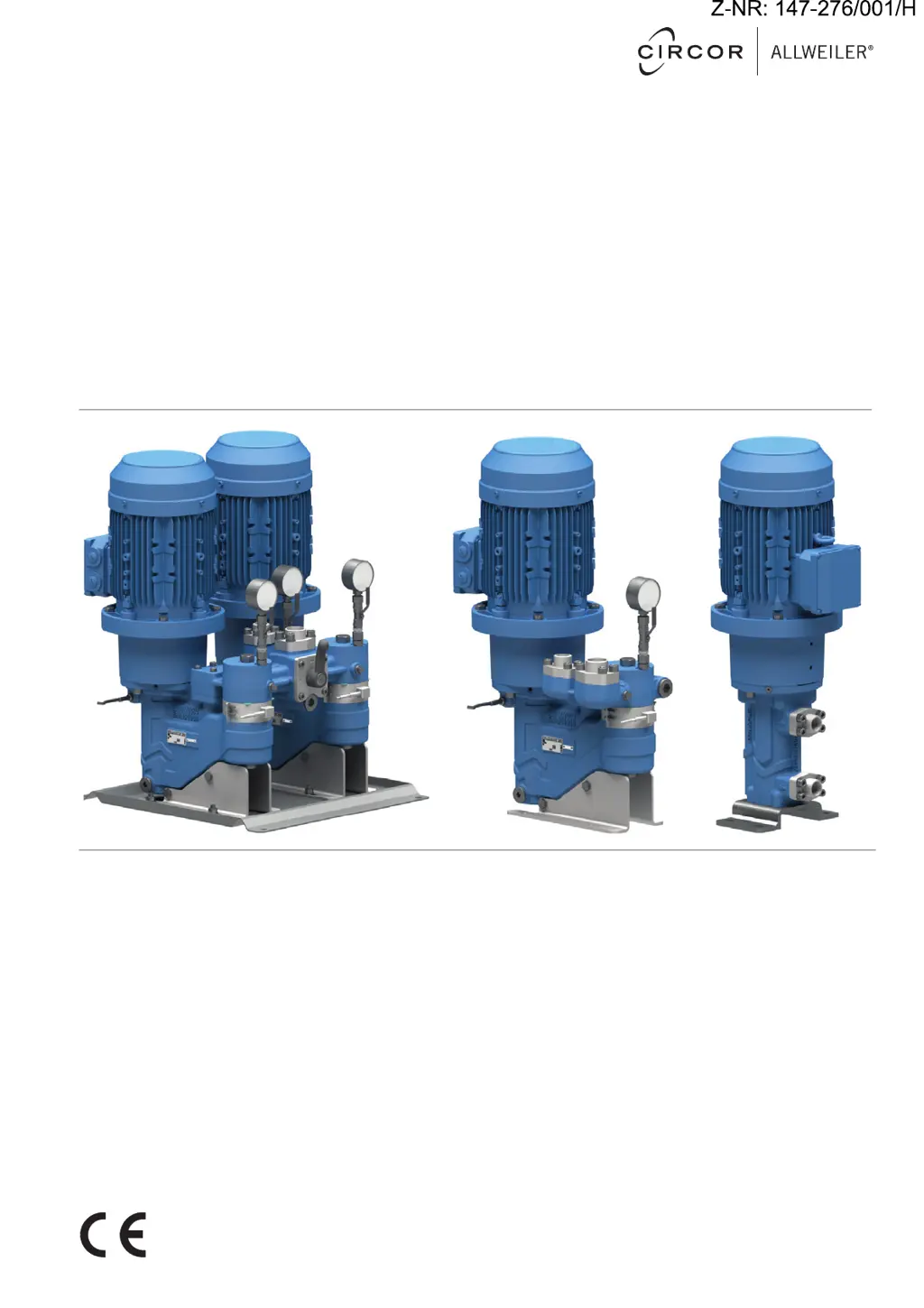

How to fix a Allweiler CIRCOR ALLFUEL that is running roughly?

- JJacob DrakeAug 29, 2025

If your Allweiler Water Pump is running roughly, it could be due to the following reasons: The pump might be very dirty, requiring you to dismount and clean it. Alternatively, the supply/suction pipe, pump, or suction strainer could be blocked or encrusted, necessitating cleaning.