16

Subject to change without notice | 83053700lUK | ait-deutschland GmbH

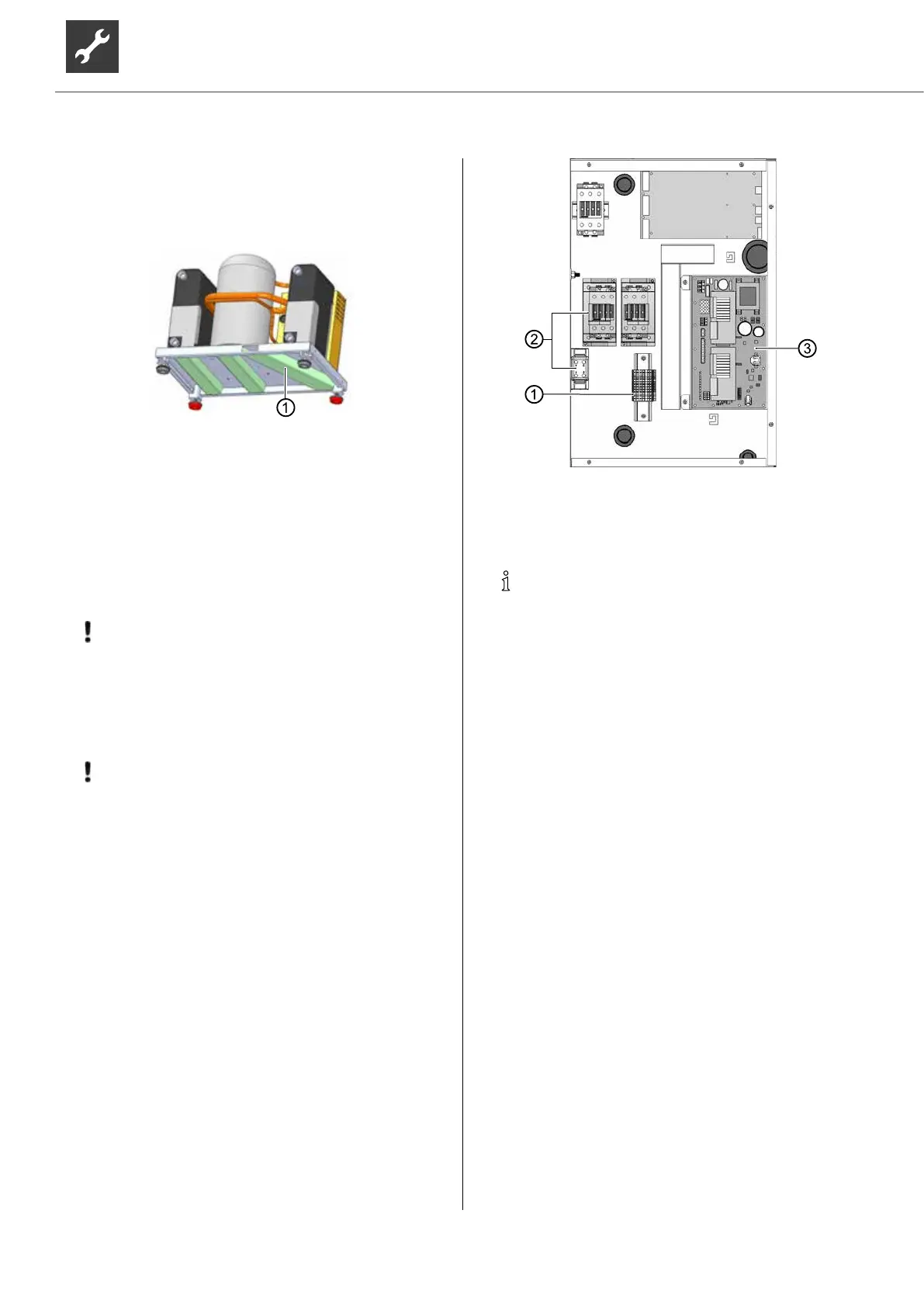

The external electric cables to be provided must be fed

through the grommets cut out in the bottom of the rear

panel and then fed into the electrical switch cabinet by

means of the cable duct, which is integrated into the

baseplate of the heat pump.

1 Cable duct

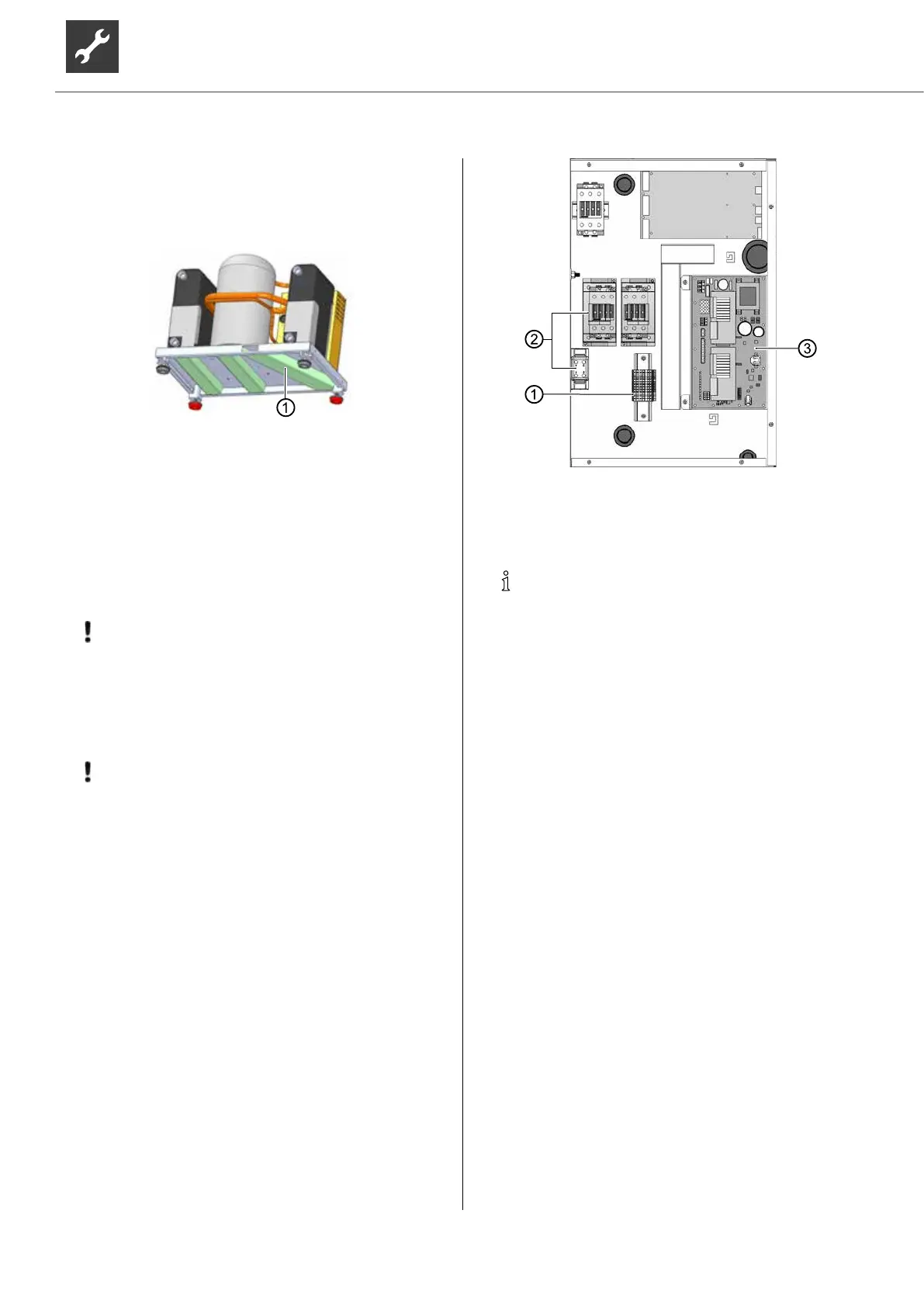

The cables laid in the switch cabinet for the regulator

(patch cable, LIN bus) must be fed through the

grommet cut out in the bottom of the rear panel.

6. Make electrical connections according to the ter-

minal diagram.

“Terminal diagram”, page 48

IMPORTANT

Ensure clockwise rotary eld of the load

power supply (compressor).

Operation with the incorrect rotary direction

of the compressor can cause serious,

irreparable damage to the compressor.

IMPORTANT

The power supply for the heat pump must be

equipped with an all-pole automatic circuit-

breaker with at least 3mm contact spacing to

IEC 60947-2.

Note the level of the tripping current.

“Technical data / scope of delivery“, from

page 22, “Electrics” section

1 Control voltage connection

2 Compressor output connection

3 Regulator board

NOTE

The control element of the heat and heat

pump regulator can be connected to a

computer or network using a suitable network

cable, enabling the heating and heat pump

regulator to be controlled remotely from there.

If such a connection is required, lay a

shielded network cable (category 6, with

RJ-45 connector) up to the control element

while carrying out the electrical connection

work.

7. After completion of all electrical installation work,

close the switch cabinet inside the unit.

8. Screw on the front panel of the unit if no further in-

stallation work inside the unit is to be performed

immediately.

Loading...

Loading...