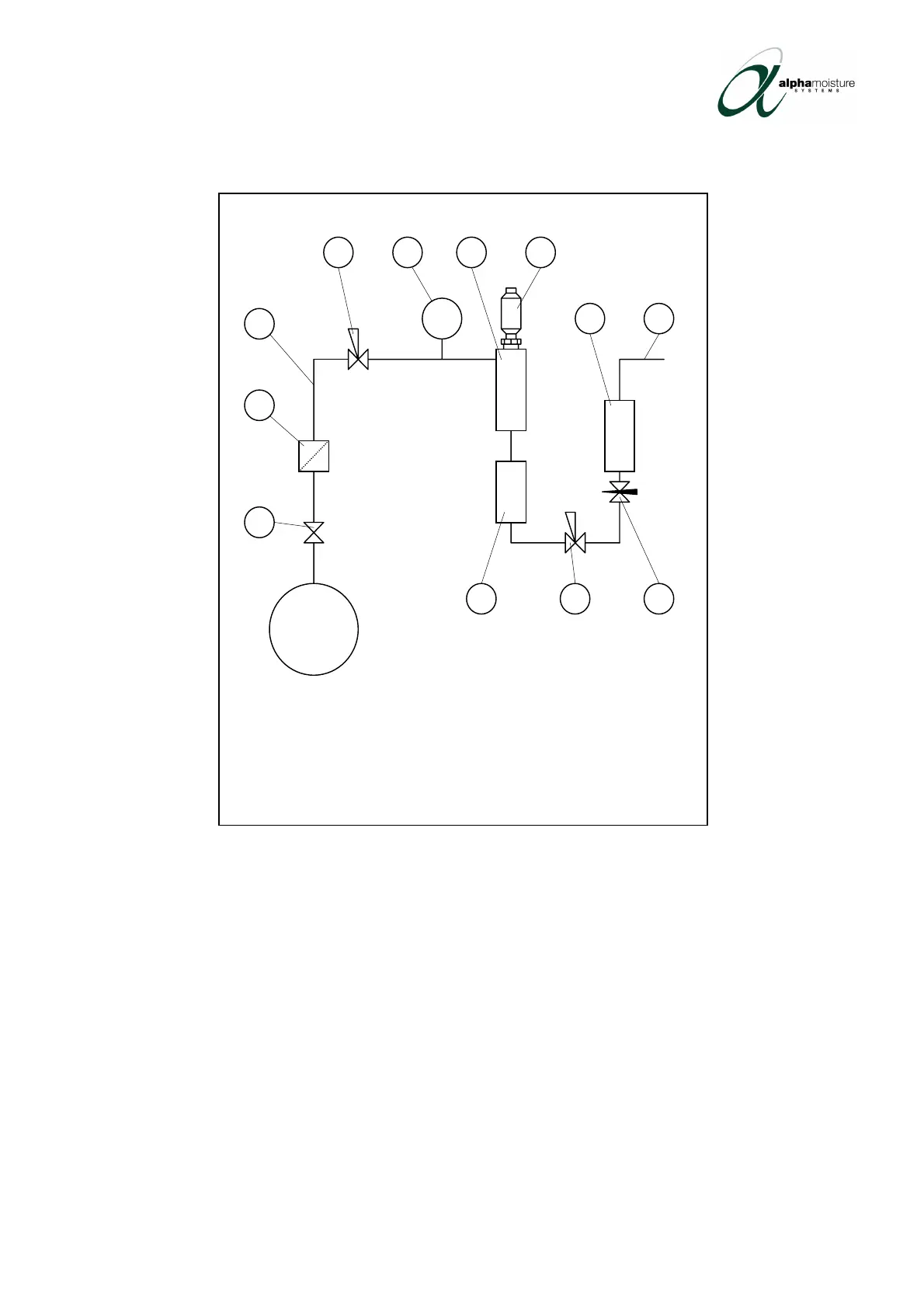

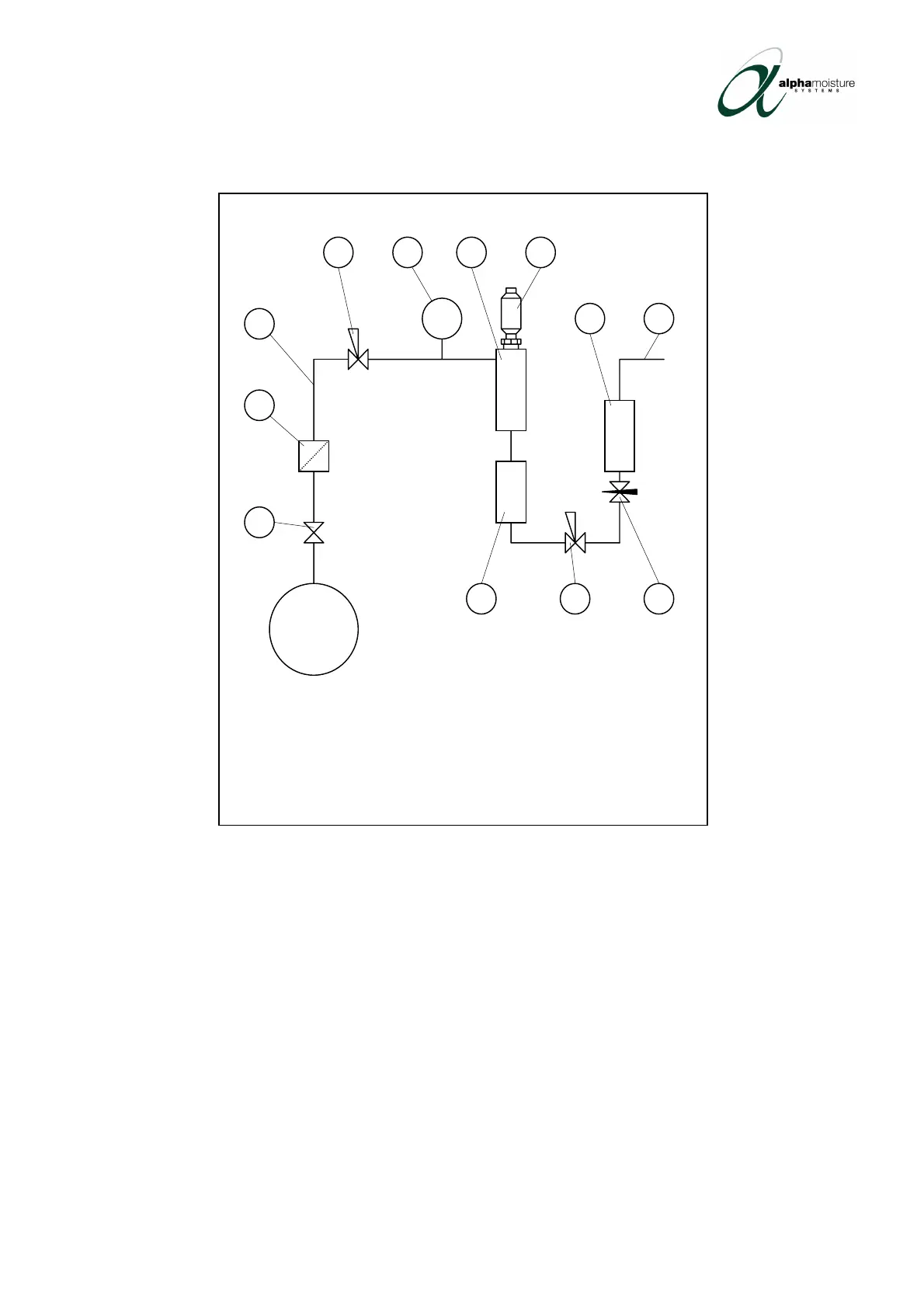

Piping installation Schematic

Notes

a. The sample point should be on the upper surface of the horizontal pipe, or f

a vertical section of pipe, wherever possible.

rom

b. The sample tube should run upwards from the sample point. If this is not

possible, then an inspection port or drain tap should be installed at the lowest

point in the sample system.

Main

Proces

s

1

4

4B

1

1

Piping Schematic Component Index

1) Sample Isolation Valve - This is a recommended item as it allows access to the sample

system without interrupting the main process line.

2) Sample Tube – This should be stainless steel for dry air or gas applications but copper

or carbon steel can be used where wetter gases are to be measured. If any section of

the sample tube must be flexible then PTFE should be used. In most cases, 3mm OD

(1/8”) is sufficient as it provides good system response time within minimum flow.

6mm OD (1/4”) tube can be used where pressure drops across the 3mm tube are too

high

3) Filter Unit – A filter unit is recommended when the samples are likely to contain

particulate matter. If the air/gas sample contains heavy hydrocarbon condensate, the

filter must be of the coalescing type with a drain. The filter unit should be positioned

as close to the sample point as practical.

dewTEC DS2000 User’s Manual Page 4

Loading...

Loading...