6.12 CO2 SET UP PROCEDURE

The air gas ratio of the boiler has been factory set and should not require adjusting during first

commission. If adjustment is recommended or required the engineer must be competent to carry out this

work.

If setting the boiler on a Hydrogen mix installation (G20Y20), for all calibration and combustion checks, refer to the

O2% values for the flue gas analysis. See Section 3.1.

Before starting this procedure please check the following:

The front case is fitted.

The flue system is not blocked or restricted and is to the correct specification.

The gas supply working pressure is correct and the system has been purged.

There is no recirculation in the boiler flue circuit.

The condensate trap is pre-filled.

If the flow temperatures are getting up to maximum operating temperature during the procedure it is possible to open a hot

tap to lose the heat.

Attention: the CO

2 checks must be carried out with the case fitted, while the gas valve adjustments must be carried out with

the front case removed.

Calibration of the maximum CO

2 (nominal DHW output)

Refer to Section 6.6 and enter the chimney sweep mode (with no DHW demand) use the DHW down button to set the output

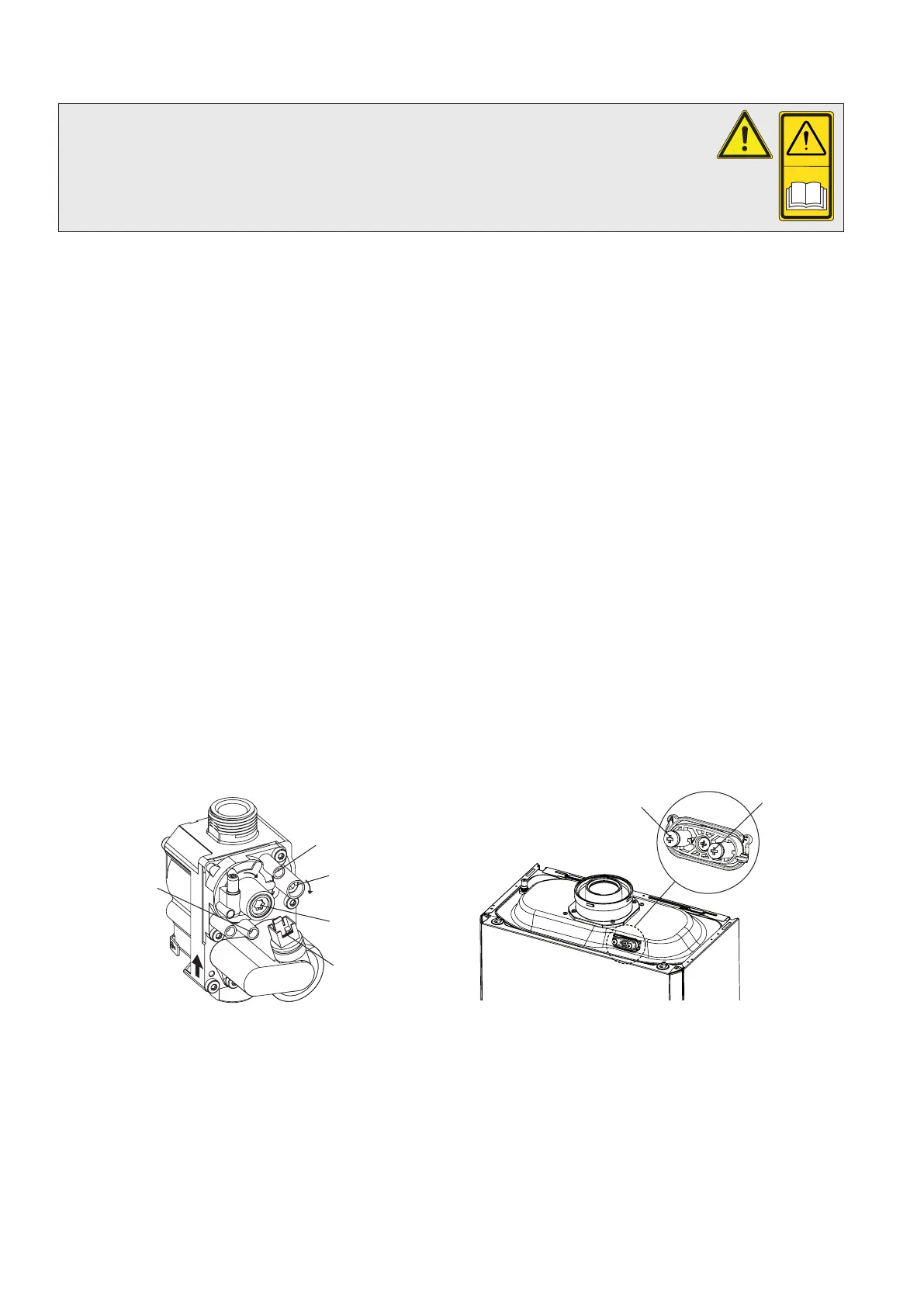

to maximum (99%). Insert the analyser probe into the flue test point (Fig. 6.3) and check that the CO

2 value is as specified

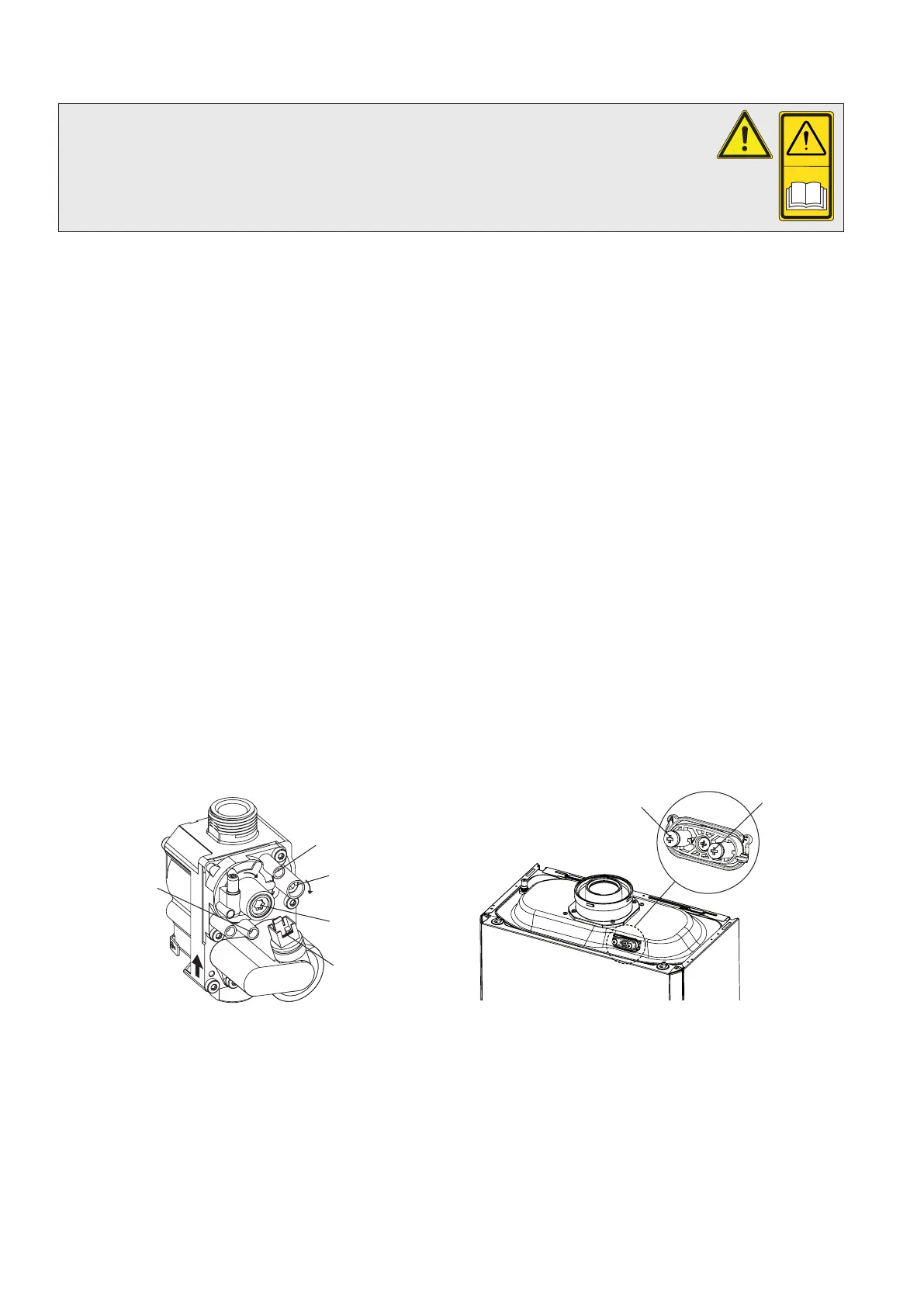

in Section 3.1, otherwise adjust the max CO2 adjuster (Fig. 6.2) To increase the CO2 value, turn the adjustment screw in a

clockwise direction and vice versa to decrease.

Calibration of the minimum CO

2 (minimum output)

When you finish the maximum CO

2 adjustment, while maintaining the chimney sweep function active, use the DHW up

button to set the output to maximum (99%). Insert the analyser probe into the flue test point (Fig. 6.3) and check that the

CO2 value is as specified in Section 3.1, otherwise adjust the min CO2 adjuster (Fig. 6.2). To increase the CO2 value, turn the

adjustment screw (Fig. 6.2) in a clockwise direction and vice versa to decrease it.

For Hydrogen Fuel Installations Only

With Hydrogen mix installation (G20Y20), when setting the maximum, if the value of O

2 as specified in Section 3.1 cannot be

reached with adjusting screw fully open, then additional adjustments are not necessary.

Alpha Evoke 28NX and 33NX - Commissioning

Fig. 6.2 Fig. 6.3

Outlet pressure

test point

Inlet pressure

test point

Wiring plug

+

+

Off/Set adjustment

screw (Min. CO )

2

Gas outlet flow

adjustment screw

(Max. CO )

2

Flue test point

F (+)

Air test point

A (-)

32

Loading...

Loading...