15

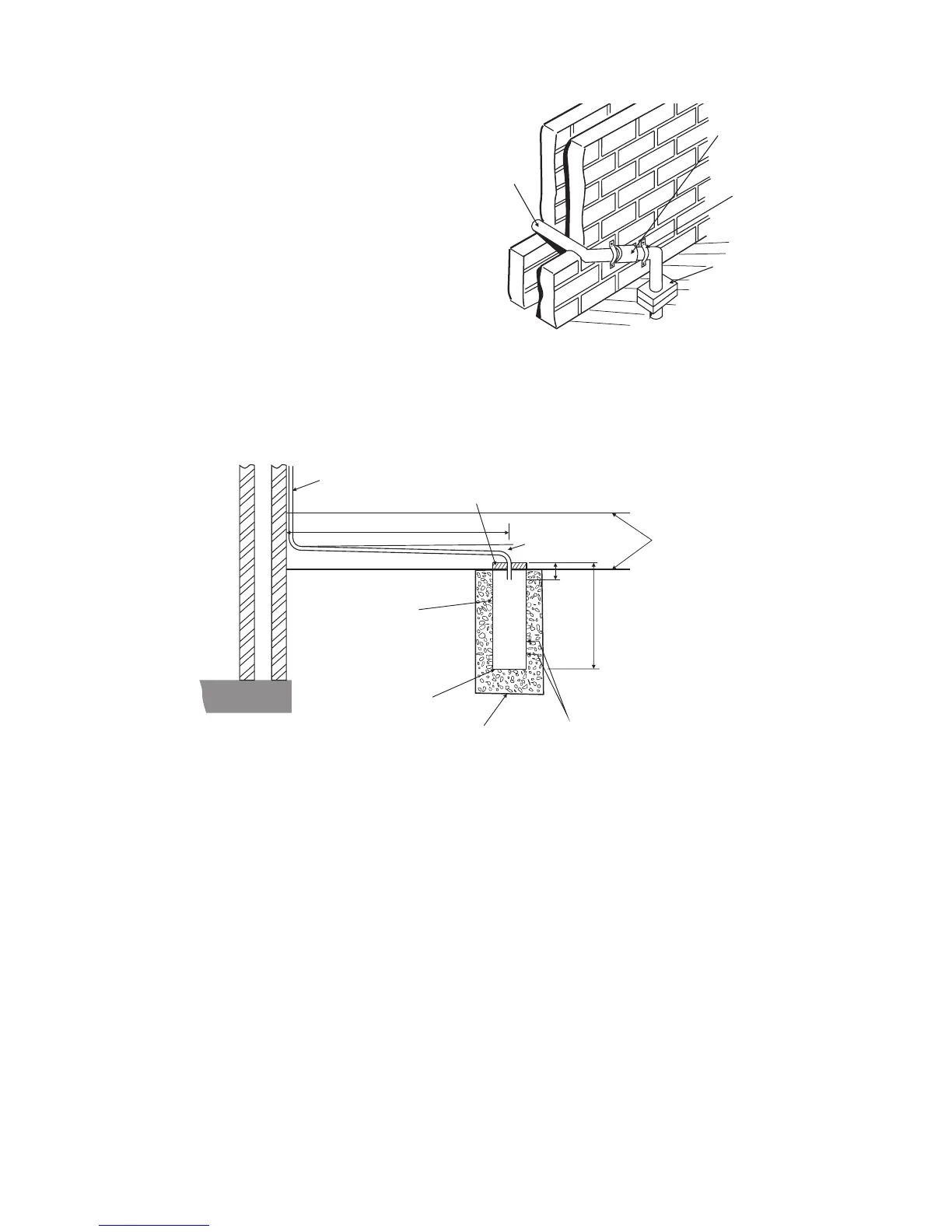

Fig. 3.8 - External soakaway

Alpha InTec² 26E, 30CE and 35CE - General Boiler Information

Ground level (either/or)

22mm termination from boiler, increase to 32 mm if external

2½ fall

O

25mm

300mm

Two rows of 3 x 12mm

holes at 25mm centres,

50mm from the bottom

of the tube. Holes to face

away from house.

Cement mortar sealing

100mm plastic tube

Bottom of tube sealed

Soakaway depth 400mm

filled with limestone chippings

500 mm min.

Optional Condensate Trace Heating Kit

An optional Alpha trace heating kit is also available

to prevent the condensate from freezing.

The control of this kit works with a unique patented

design using the boiler PCB to control the trace

heating. The outside weather probe measures the

external temperature, activating the trace heating

cable only when the boiler is in operation and

producing condensate. This feature together with

the latest technology variable resistance heating

cable ensures only a small amount of electrical

energy is used.

If the external temperature drops below 2°C

and the boiler is on, the relay PCB is operated

and voltage is supplied to the trace heating wire

causing it to heat up and prevent the condensate

from freezing. When the outside temperature rises

to 4°C or the boiler pump stops, the trace heater

is switched off. The connection of the outside weather probe supplied with this kit also enables the weather compensation

feature on the boiler.

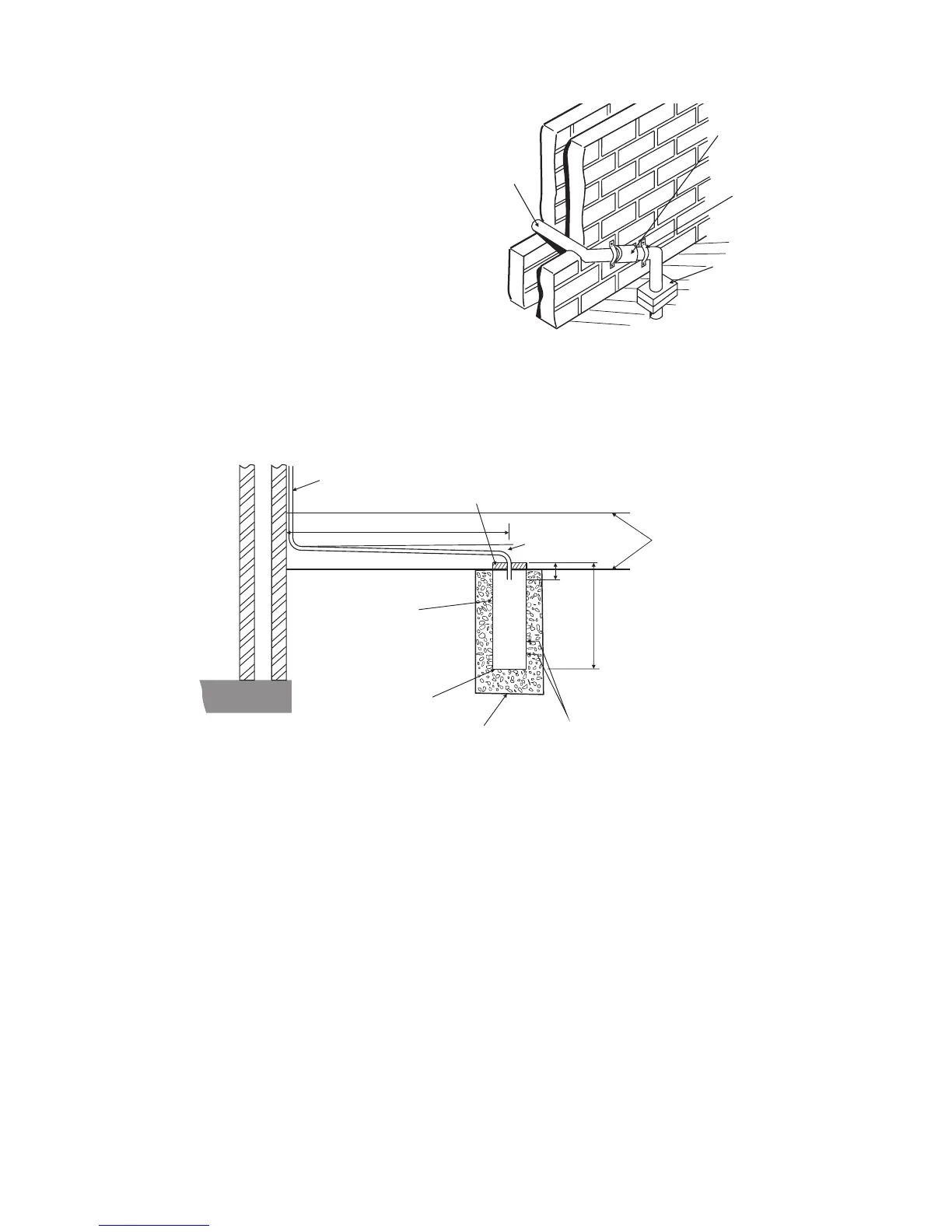

Fig. 3.7 - External gully

Open end of pipe

diverted into gully

below grid but above

water level

Use waterproof

pipework insulation

in very exposed

positions

Ensure pipe is

Plastic pipe

(minimum 32 mm)

Minimum gradient 2½°

3.11 DOMESTIC HOT WATER SYSTEM

The minimum flow rate needed for the flow switch and burner to operate is 1.5 litres/min.

If the incoming mains water pressure is above 5 bar a pressure reducing valve must be fitted.

If the mains supply is fitted with a water meter, check valves or loose jumper stop cock, then a DHW expansion device must

be fitted.

Following Part L Building Regulations, where the mains water hardness exceeds 200 parts per million, provision should be

made to treat the feed water to the hot water circuit of combination boilers to reduce the rate of accumulation of limescale.

To ensure economic use, the pipe runs between the boiler and taps should be in 15 mm copper pipe and be as short as

possible. Where possible the pipework should be insulated to reduce heat loss.

All taps and mixing valves used with the hot water system must be suitable for operating at a mains pressure of up to 8 bar.

Showers - A shower may be used with the boiler if required.

If a loose or flexible head type shower is used it may require the fitting of a double check valve, to comply with Water Bye Law 17.

Bidets - No anti-syphonage arrangements are necessary, provided the outlets are shrouded and it is not possible to attach

a temporary hand held spray. A supply of direct mains fed hot and cold water is permitted provided the appliance is of the

over-rim flushing type.

Before the mains water supply pipe is connected to the boiler, it should be thoroughly flushed out to avoid the danger of dirt

or foreign matter entering the boiler.

Loading...

Loading...