6

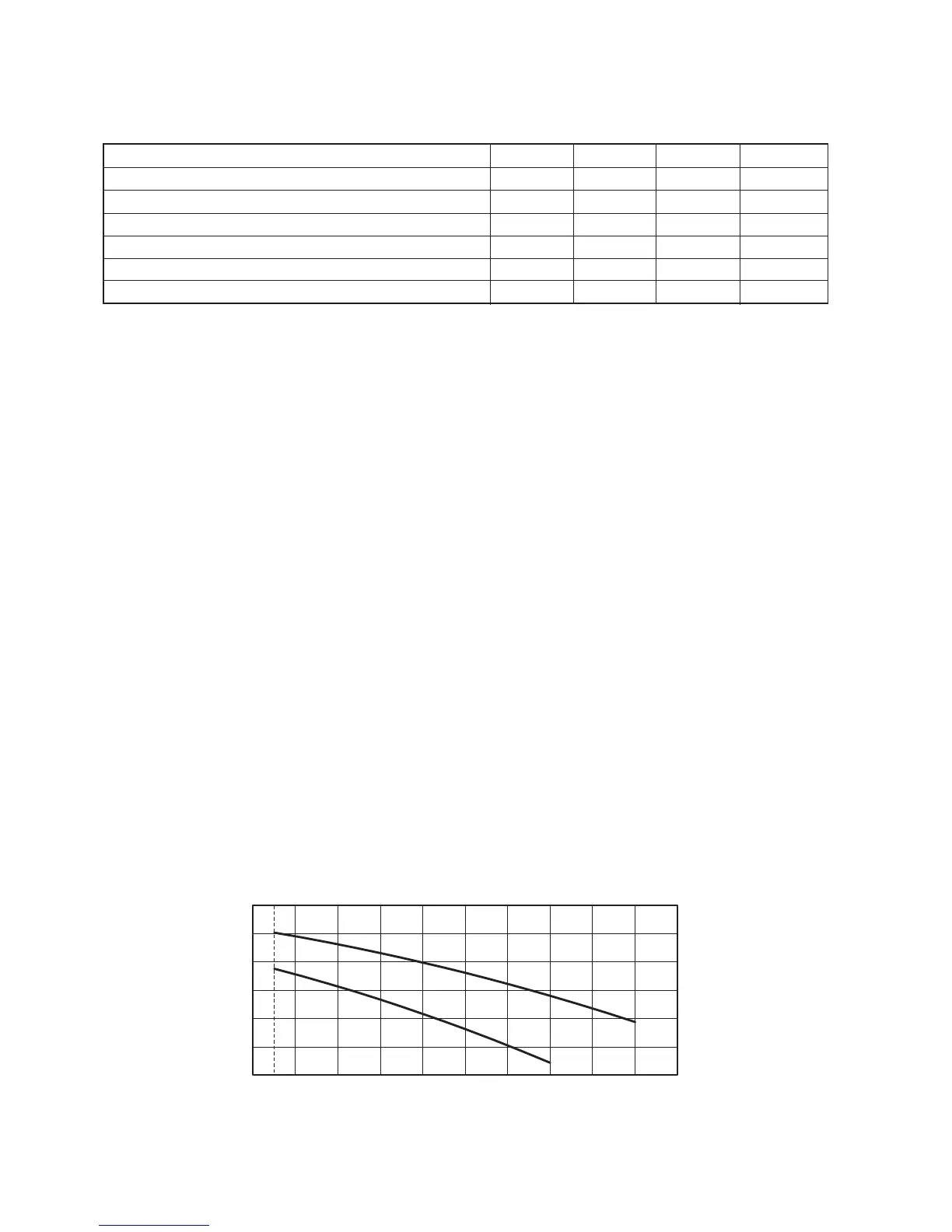

* Maximum Flue Lengths (includes rst bend onto boiler ue connection for horizontal installations)

* Max. ue length 80/125 concentric (room sealed) m

* Max. ue length 80 single pipe (B23 open ue) m

Flue system (optional) Concentric ue mm

Hole in wall required mm

Flue system (as supplied) Open ue mm

Hole in wall required mm

11

28

80/125

127

80

100

8

14

80/125

127

80

100

5

8.5

80/125

127

80

100

14.5

30

80/125

127

80

100

Pro Tec 115Pro Tec 50 Pro Tec 70 Pro Tec 90

Open ue - Maximum horizontal or vertical ue with single 80 mm dia. according to Table above

90° bend is equivalent to 2.1 m of ue length

45° bend is equivalent to 1.3 m of ue length

Vertical terminal is equivalent to 2 m of ue length

Concentric ue - Maximum horizontal ue or vertical ue according to Table above

90° bend is equivalent to 1.9 m of ue length

45° bend is equivalent to 1.4 m of ue length

Vertical terminal is equivalent to 2 m of ue length

Notes: 1. Ensure all ues slope downwards towards the boiler by a minimum of 25 to 30 mm per metre of ue.

2. It is recommended that horizontal and vertical ue assemblies should be supported approximately every 1.5 m with

access provided to the joints.

3. These dimensions only apply for ue parts supplied by Alpha.

Cascade ue options are also available, please contact Alpha for further details.

2.4 FLUE DATA

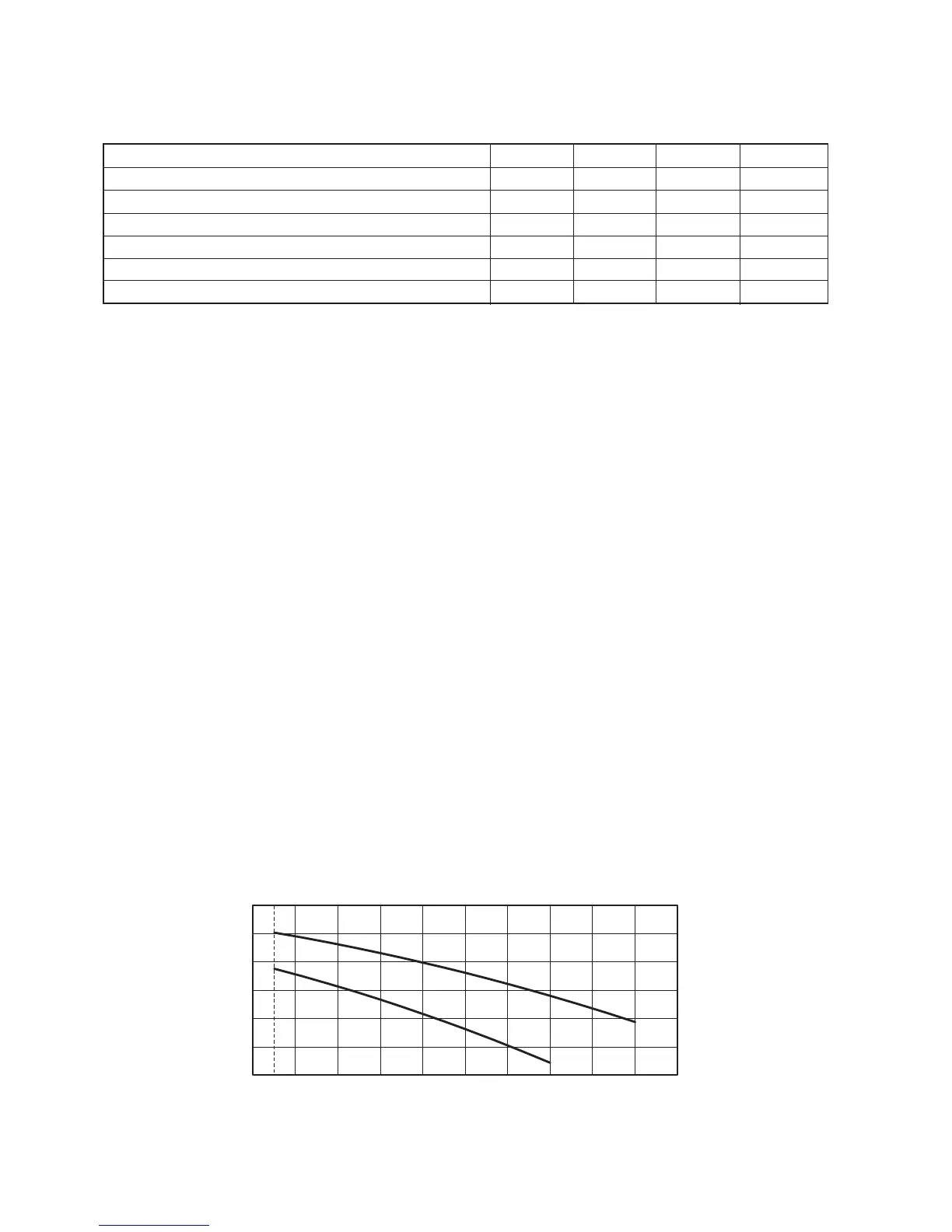

2.5 AVAILABLE PUMP HEAD

Fig. 2.1

The Pro Tec boilers are tted with a 3 speed pump. The boiler does not operate correctly with the pump set at the slowest

speed. To ensure optimal boiler operation, especially in the case of new systems it is recommended that the pump is set to

maximum speed.

The following graphs indicate the pump head and ow rates available at the maximum speed setting (A) and the middle

speed setting (B).

Pump release: If, after a prolonged period of inactivity, the pump is sticking, unscrew the front cap and turn the motor shaft

using a at bladed screwdriver. Take great care during this operation to avoid damage to the motor.

For larger systems an additional external pump can be tted and controlled by the boiler using a relay switch. See Fig. 2.5.

A

B

1.0

2.0

3.0

4.0

5.0

6.0

0

Flow rate (l/h)

Head

(m water)

800 850 1000 1100 1200 1300 1400 1500 1600 1700 1800900

Pro Tec 50

Alpha Pro Tec - Data

Loading...

Loading...