DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015

2

1.0 OVERVIEW

1.1 For help locating subjects in this document, a section index is provided on page 68.

A glossary of technical terms begins on page 66.

1.2 The Altronic DE-3000+ controller system is an electronic, microprocessor-based

system designed to sense various analog and digital input points to control and

monitor industrial compressors. The system is field-programmable using a PC

and the supplied terminal program and contains a non-volatile memory to store

the setup. A panel-mounted 10" color MIDAS HMI serves as the user interface.

The DE-3000+ provides for both the safety shutdown functions needed to pre-

vent unnecessary damage to remotely-operated equipment and the closed-loop

automatic control functions needed to optimize their efficiency of operation.

The DE-3000+ also provides for remote data acquisition and supervisory con-

trol in a compact, low cost package for industrial compressor applications. The

optimization strategies available for the management of compressor throughput

include automatic prime mover speed setting as well as capacity control. On

rotary screw compressors, capacity control can be done via suction throttling,

or using an internal gas bypass technique employing poppet valves, turn valves

or slide valves. On reciprocating compressors, capacity can be controlled us-

ing external gas bypass loops or pressure regulation techniques. A wide range

of output options, including both analog current loops and digital outputs, are

provided to interface with the large variety of actuation systems currently in use.

In addition, automatic load limiting based upon prime mover power capabilities

or other application specific limitations, such as cooling capacity, are readily

implemented. There are also AUTO START and OEM ENGINE CONTROL options

that are enabled using the terminal program.

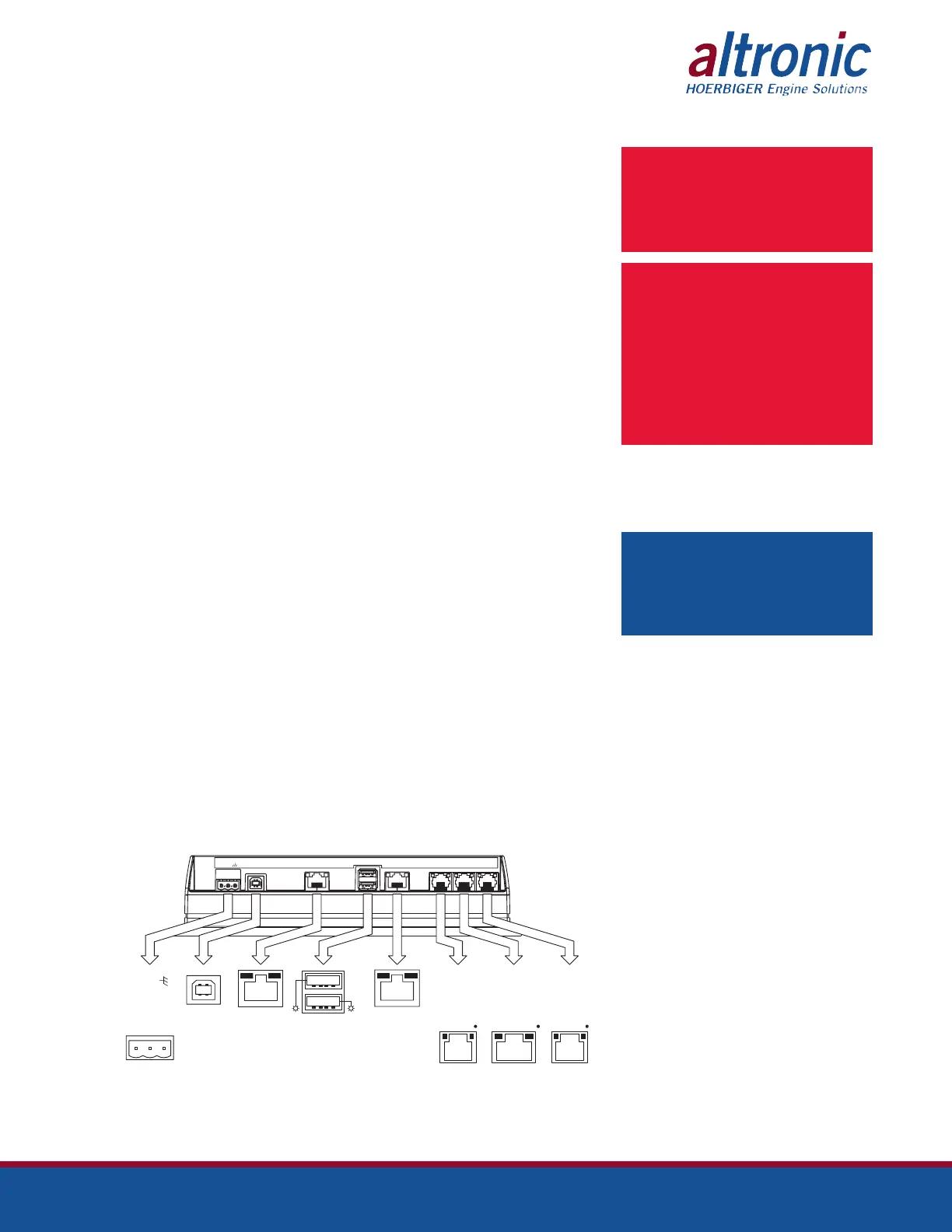

1.3 The DE-3000+ has four components: 10" color MIDAS HMI (G10S0000),

computer module (DE-3000+), terminal module (691171-1), and power supply

module (691122-1). The MIDAS HMI and the computer module communicate

via the Ethernet port using a CAT 5e cable. The computer module connects to

the terminal module via a DB-25 cable. An additional terminal board may be

added for 30 extra channels (691171-2) or 15 extra channels (691175-2). This

increases the channel selections from 1-30 to 1-60 or 1-45 respectively.

To download the terminal program, a DB-9 cable must be connected to the to

the DE-3000+.

2.0 10" COLOR MIDAS HMI

2.1 The 10" color MIDAS HMI serves as the user interface for the DE-3000+ sys-

tem. It is a VGA color standard touchscreen (640 x 480) outdoor model. The

MIDAS HMI has one 10/100 Base-TX Ethernet Port and three fully isolated Se-

rial Communication Ports (two RS-232 and one RS-422/485). In addition, the

MIDAS HMI has one USB Type B Port and two High-retention USB Host Ports.

WARNING: THE CONTROLLER SYSTEM

MUST BE CONFIGURED PRIOR TO USE

ON A COMPRESSOR SYSTEM. REFER-

ENCE THE PROGRAMMING INSTRUC-

TIONS (PAGE 43) FOR INSTRUCTIONS

DESCRIBING HOW TO CONFIGURE THE

CONTROLLER FOR THE SPECIFIC AP-

PLICATION. VERIFY THE PROGRAM IN

NONVOLATILE MEMORY (THE EEPROM)

PRIOR TO STARTING THE SYSTEM.

WARNING: DEVIATION FROM THESE

INSTRUCTIONS MAY LEAD TO IMPROP-

ER ENGINE OPERATION WHICH COULD

CAUSE PERSONAL INJURY TO OPERA-

TORS OR OTHER NEARBY PERSONNEL.

NOTE: THE DE-3000+ REQUIRES

TWO 10-32VDC, 0.2A (MAX) POWER

SOURCES, ONE FOR THE POWER SUP-

PLY BOARD AND THE OTHER FOR THE

COMPUTER MODULE.

TYPE B

USB

STATUS

USB HOST

STATUS

PORT B

PORT A

COMM

RTS (PIN 6)

Tx

CTS (PIN 1)

Rx

COMM

RTS (PIN 6)

Rx

COMM

Tx

COMM

CTS (PIN 1)

(NIC)

ETHERNET

RxB

TxA (PIN 8)

COMM

TxB

TxEN

TxB (PIN 1)

RxA

TxA

AUXILIARY

ETHERNET

(NIC)

COMMS PORTPGM PORT COMMS PORT

RS232 RS485 RS232

DEVICE

USBPOWER

-

+

USB HOST

PORT A (PGM)

ETHERNET

RS232 RS232

PORT BPORT A

RS485

AUXILIARY

ETHERNET

POWER

CHASSIS

COMMON

+DC VOLTAGE

1

2

3

CONNECTOR

[OPTIONAL]

Loading...

Loading...