18

2. With the unit operating, time the smallest dial on the

meter for one complete revolution. If this is a 2 cubic

foot dial, divide the seconds by 2; if it is a 1 cubic foot

dial, use the seconds as is. This gives the seconds

per cubic foot of gas being delivered to the unit.

3. ,1387 *$6+7*9$/8([6(&3(5&8%,&

FOOT

EXAMPLE: Natural gas with a heating value of 1000 BTU

per cubic foot and 34 seconds per cubic foot as determined

E\6WHSWKHQ

Input = 1000 x 3600 / 34 = 106,000 BTU per Hour.

127(%78උඖගඍඖගඎගඐඍඏඉඛඛඐඝඔඌඊඍඊගඉඑඖඍඌ

ඎකඕගඐඍඏඉඛඛඝඔඑඍක7ඐඑඛඕඍඉඛඝකඍඌඑඖඝගඕඝඛග

ඖගඊඍඏකඍඉගඍකගඐඉඖඛඐඟඖඖගඐඍඝඖඑගකඉගඑඖඏඔඉගඍ

4. 5HOLJKWDOORWKHUDSSOLDQFHVWXUQHGRႇLQVWHS%H

sure all pilot burners are operating.

Main Burner Flame Check

)ODPHVVKRXOGEHVWDEOHVRIWDQGEOXHGXVWPD\FDXVH

RUDQJHWLSVEXWWKH\PXVWQRWEH\HOORZDQGH[WHQGLQJ

GLUHFWO\RXWZDUGIURPWKHEXUQHUZLWKRXWFXUOLQJÀRDWLQJRU

OLIWLQJRႇ

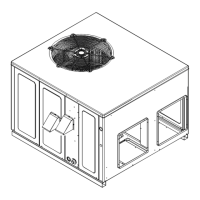

7ඍඕඍකඉගඝකඍ5එඛඍ&ඐඍඋඓ

Check the temperature rise through the unit by placing

thermometers in supply and return air registers as close

to the unit as possible. Thermometers must not be able to

sample temperature directly from the unit heat exchangers,

or false readings could be obtained.

&ඐඍඋඓඑඖඏ7ඍඕඍකඉගඝකඍ5එඛඍ

1. All registers must be open; all duct dampers must be

LQWKHLU¿QDOIXOO\RUSDUWLDOO\RSHQSRVLWLRQDQGWKH

unit operated for 15 minutes before taking readings.

2. The temperature rise must be within the range speci-

¿HGRQWKHUDWLQJSODWH

127($එකගඍඕඍකඉගඝකඍකඑඛඍඑඛගඐඍගඍඕඍකඉගඝකඍ

ඌඑඎඎඍකඍඖඋඍඊඍගඟඍඍඖඛඝඔඡඉඖඌකඍගඝකඖඉඑක

With a properly designed system, the proper amount of

temperature rise will normally be obtained when the unit

is operated at rated input with the recommended blower

speed.

If the correct amount of temperature rise is not obtained,

it may be necessary to change the blower speed. A high-

er blower speed will lower the temperature rise. A slower

blower speed will increase the temperature rise.

127(%ඔඟඍකඛඍඍඌ0867ඊඍඛඍගගඏඑඞඍගඐඍ

උකකඍඋගඉඑකගඍඕඍකඉගඝකඍකඑඛඍගඐකඝඏඐගඐඍඝඖඑගඉඛ

ඕඉකඓඍඌඖගඐඍකඉගඑඖඏඔඉගඍ

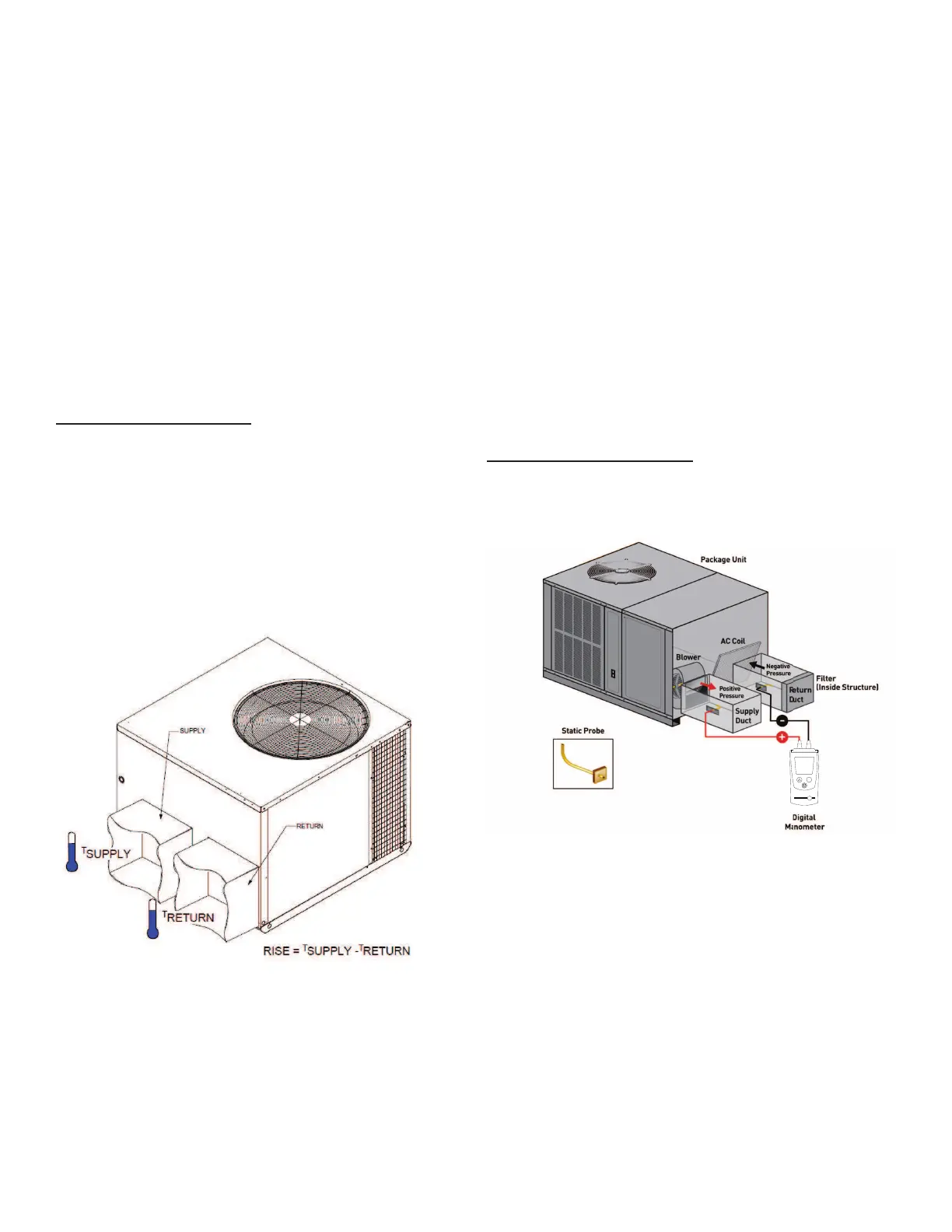

(චගඍකඖඉඔ6ගඉගඑඋ3කඍඛඛඝකඍ&ඐඍඋඓ

The total external static pressure must be checked on this

XQLWWRGHWHUPLQHLIWKHDLUÀRZLVSURSHU

Total External Static Testing

1. Using a digital manometer measure the static pres-

VXUHRIWKHUHWXUQGXFWDWWKHLQOHWRIWKHXQLW1HJDWLYH

3UHVVXUH

.

Mode

.

7ගඉඔ(චගඍකඖඉඔ6ගඉගඑඋ

2. 0HDVXUHWKHVWDWLFSUHVVXUHRIWKHVXSSO\GXFW3RVL-

WLYH0HDVXUH

3. Add the two readings together.

127(%ගඐකඍඉඌඑඖඏඛඕඉඡඊඍගඉඓඍඖඛඑඕඝඔගඉඖඍඝඛඔඡ

ඉඖඌකඍඉඌඌඑකඍඋගඔඡඖගඐඍඕඉඖඕඍගඍකඑඎඛඌඍඛඑකඍඌ

4. Consult proper table for quantity of air.

If the external static pressure exceeds the minimum or

maximum allowable statics. Check for closed dampers,

GLUW\¿OWHUVXQGHUVL]HGRUSRRUO\ODLGRXWGXFWZRUN

Loading...

Loading...