21

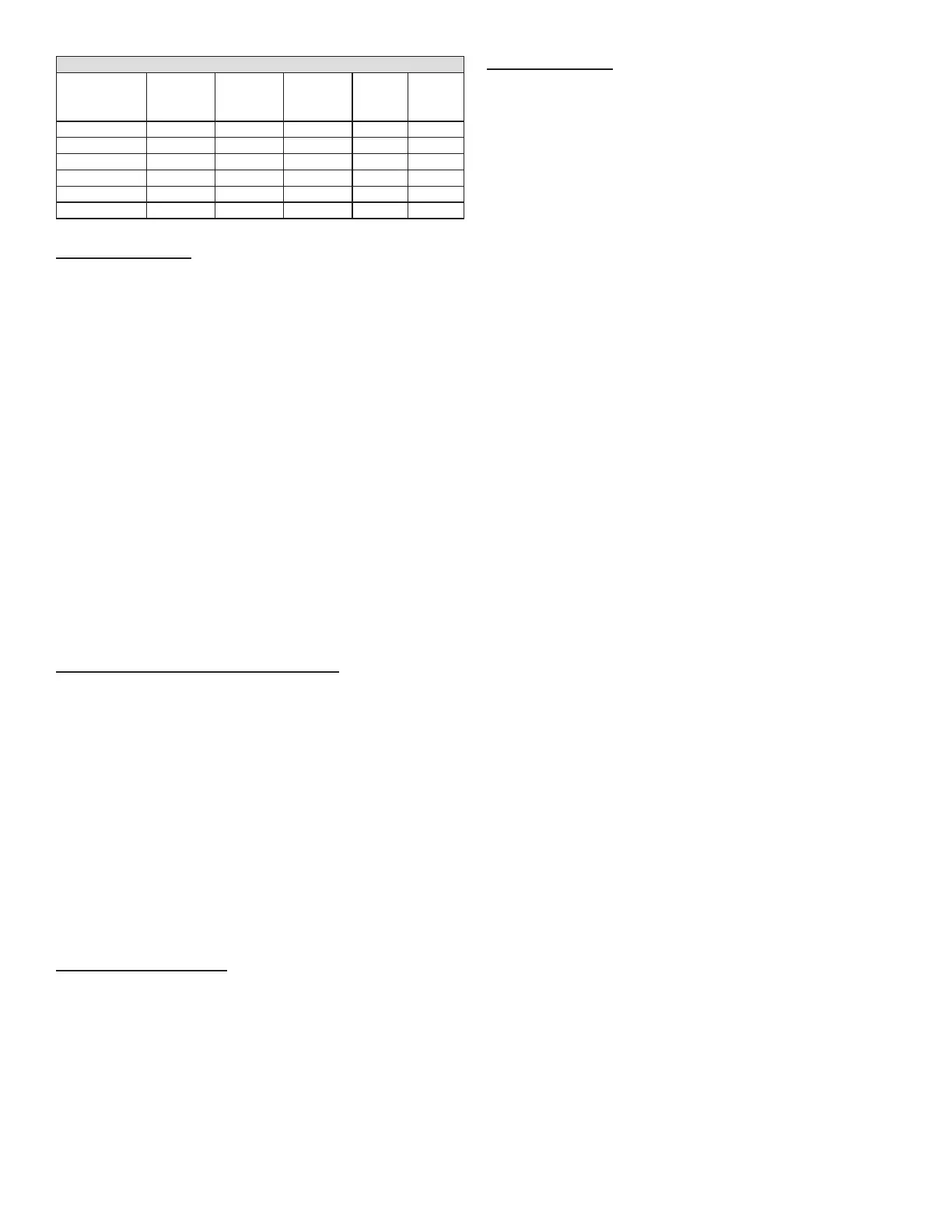

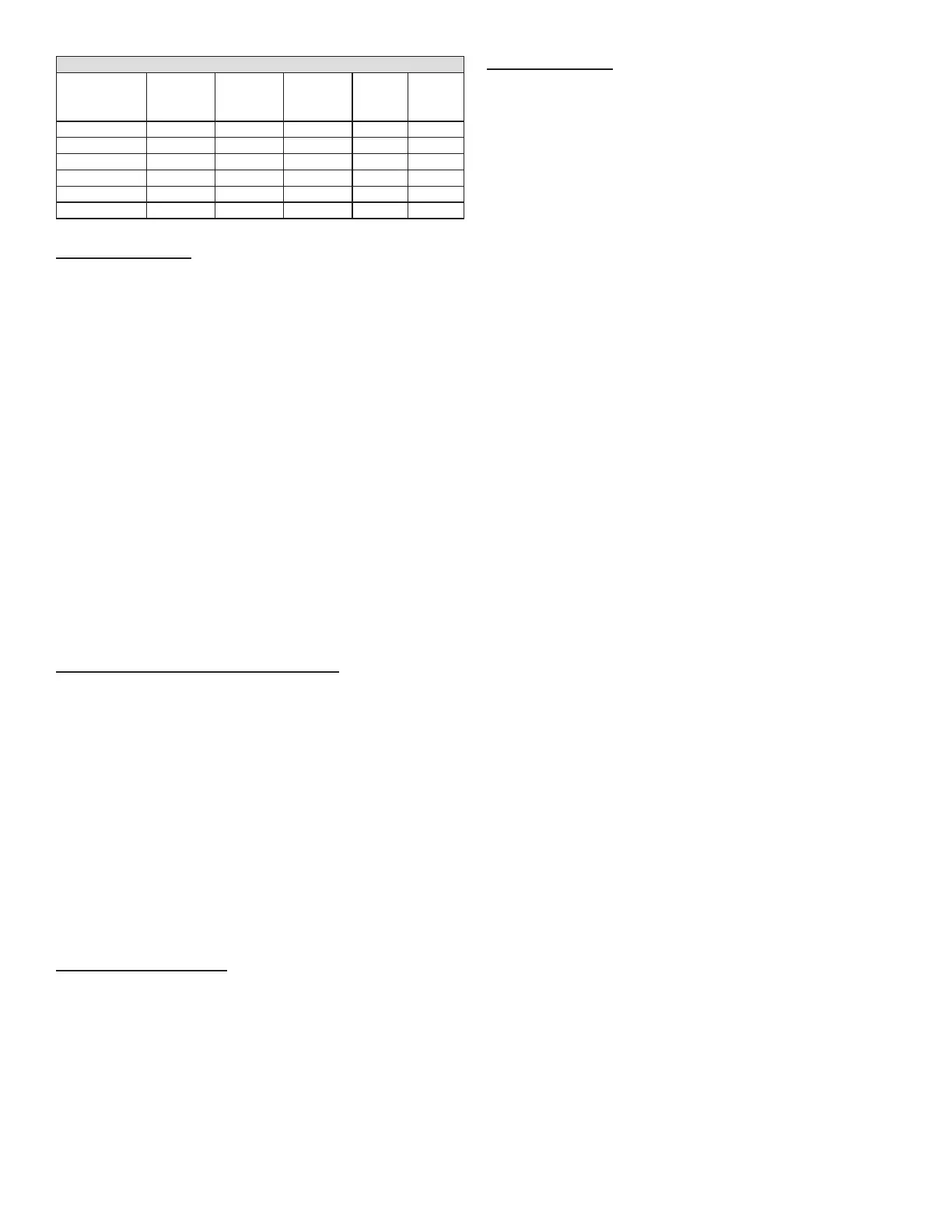

Model

Superheat

±2°F

Subcooling

±1°F

Expansion

Device

Cooling

Stage

Ambient

*PGM324***41 7 - Piston high 95

*PGM330***41 4 - Piston high 95

*PGM336***41 5 - Piston high 95

*PGM342***41 7 - Piston high 95

*PGM348***41 15 - Piston high 95

*PGM361***41 6 8 TXV low 82

Design Superheat & Subcool

Cooling Operation

127(0ඍඋඐඉඖඑඋඉඔඋඔඑඖඏඋඉඖඖගඊඍකඍඔඑඉඊඔඡක-

ඞඑඌඍඌඉගඉඕඊඑඍඖගගඍඕඍකඉගඝකඍඛඊඍඔඟ)

1. Turn on the electrical power supply to the unit.

2. Place the room thermostat selector switch in the

&22/SRVLWLRQRU$872LIDYDLODEOHDQGLIDXWRPDWLF

FKDQJHRYHUIURPFRROLQJWRKHDWLQJLVGHVLUHG

3. Set the room thermostat to the desired temperature.

TROUBLESHOOTING

,ඏඖඑගඑඖ&ඖගකඔ(කකක&ඌඍඛ

The following presents probable causes of questionable

unit operation. Refer to Diagnostic Indicator Chart for

an interpretation of the signal and to this section for an

explanation.

Remove the control box access panel and note the number

RIGLDJQRVWLF/('ÀDVKHV5HIHUWR'LDJQRVWLF,QGLFDWRU

Chart for an interpretation of the signal and to this section

for an explanation.

)DXOW5HFDOO7ZR6WDJH0RGHOV21/<

The ignition control is equipped with a momentary

push-button switch that can be used to display on the diag-

QRVWLF/('WKHODVW¿YHIDXOWVGHWHFWHGE\WKHFRQWURO7KH

FRQWUROPXVWEHLQ6WDQGE\0RGHQRWKHUPRVWDWLQSXWVWR

use the feature. Depress the push-button switch for approx-

imately 2 seconds. NOTE: Do not hold for longer than 4

seconds. Holding the button for 4 seconds or higher

will erase the memory! Release the switch when the

/('LVWXUQHGRႇThe diagnostic LED will then display

WKHÀDVKFRGHVDVVRFLDWHGZLWKWKHODVW¿YHGHWHFWHGIDXOWV

The order of display is the most recent fault to the least

recent fault.

$2+

Internal Control Failure

If the integrated ignition control in this unit encounters an

LQWHUQDOIDXOWLWZLOOJRLQWRD³KDUG´ORFNRXWDQGWXUQRႇWKH

diagnostic LED. If diagnostic LED indicates an internal

fault, check power supply to unit for proper voltage, check

all fuses, circuit breakers and wiring. Disconnect electric

SRZHUIRU¿YHVHFRQGV,I/('UHPDLQVRႇDIWHUUHVWRULQJ

power, replace control.

External Lockout

An external lockout occurs if the integrated ignition control

determines that a measurable combustion cannot be estab-

OLVKHGZLWKLQWKUHHFRQVHFXWLYHLJQLWLRQDWWHPSWV,IÀDPH

LVQRWHVWDEOLVKHGZLWKLQWKHVHYHQVHFRQGWULDOIRULJQL-

tion, the gas valve is de-energized, 15 second inter-purge

cycle is completed, and ignition is reattempted. The control

will repeat this routine three times if a measurable com-

EXVWLRQLVQRWHVWDEOLVKHG7KHFRQWUROZLOOWKHQVKXWRႇWKH

induced draft blower and go into a lockout state.

,IÀDPHLVHVWDEOLVKHGEXWORVWWKHFRQWUROZLOOHQHUJL]H

the circulator blower at the heat speed and then begin a

QHZLJQLWLRQVHTXHQFH,IÀDPHLVHVWDEOLVKHGWKHQORVWRQ

VXEVHTXHQWDWWHPSWVWKHFRQWUROZLOOUHF\FOHIRUIRXU

FRQVHFXWLYHLJQLWLRQDWWHPSWV¿YHDWWHPSWVWRWDOEHIRUH

locking out.

7KHGLDJQRVWLFIDXOWFRGHLVÀDVKIRUDORFNRXWGXHWR

IDLOHGLJQLWLRQDWWHPSWVRUÀDPHGURSRXWV7KHLQWHJUDWHG

control will automatically reset after one hour, or it can be

reset by removing the thermostat signal or disconnecting

WKHHOHFWULFDOSRZHUVXSSO\IRURYHU¿YHVHFRQGV,IWKH

diagnostic LED indicates an external lockout, perform the

IROORZLQJFKHFNV

&KHFNWKHVXSSO\DQGPDQLIROGSUHVVXUHV

&KHFNWKHJDVRUL¿FHVIRUGHEULV

&KHFNJDVYDOYHIRUSURSHURSHUDWLRQ

&KHFNVHFRQGDU\OLPLW

$GLUW\¿OWHUH[FHVVLYHGXFWVWDWLFLQVXႈFLHQWDLUÀRZD

faulty limit, or a failed circulator blower can cause this limit

WRRSHQ&KHFN¿OWHUVWRWDOH[WHUQDOGXFWVWDWLFFLUFXODWRU

EORZHUPRWRUEORZHUPRWRUVSHHGWDSVHHZLULQJGLD-

JUDPDQGOLPLW$QLQWHUUXSWLRQLQHOHFWULFDOSRZHUGXULQJ

a heating cycle may also cause the auxiliary limit to open.

The automatic reset secondary limit is located on top of the

circulator blower assembly.

&KHFNUROORXWOLPLW

,IWKHEXUQHUÀDPHVDUHQRWSURSHUO\GUDZQLQWRWKHKHDW

H[FKDQJHUWKHÀDPHUROORXWSURWHFWLRQGHYLFHZLOORSHQ

3RVVLEOHFDXVHVDUHUHVWULFWHGRUEORFNHGÀXHSDVVDJHV

blocked or cracked heat exchanger, a failed induced draft

EORZHURULQVXႈFLHQWFRPEXVWLRQDLU7KHUROORXWSURWHFWLRQ

device is a manual reset limit located on the burner brack-

HW7KHFDXVHRIWKHÀDPHUROORXWPXVWEHGHWHUPLQHGDQG

corrected before resetting the limit.

&KHFNÀDPHVHQVRU

$GURSLQÀDPHVLJQDOFDQEHFDXVHGE\QHDUO\LQYLVLEOH

coating on the sensor. Remove the sensor and carefully

clean with steel wool.

&KHFNZLULQJ

Check wiring for opens/shorts and miswiring.

IMPORTANT:,ඎඡඝඐඉඞඍගඎකඍඝඍඖගඔඡකඍඛඍගඡඝක

ඏඉඛඍඔඍඋගකඑඋඉඋඓඉඏඍඝඖඑගඑගඕඍඉඖඛගඐඉගඉකඊඔඍඕ

ඍචඑඛගඛගඐඉගඛඐඝඔඌඊඍඋකකඍඋගඍඌ&ඖගඉඋගඉඝඉඔඑ-

ඎඑඍඌඛඍකඞඑඋඍකඎකඎඝකගඐඍකඑඖඎකඕඉගඑඖ

Loading...

Loading...