8

The rating plate is stamped with the model number, type of

gas and gas input rating. Make sure the unit is equipped to

operate on the type of gas available. Conversion to LP gas

is permitted with the use of the factory authorized conver-

sion kit LPM-07, for use with single stage models, or LPM-

08, for use with two-stage models. See table below.

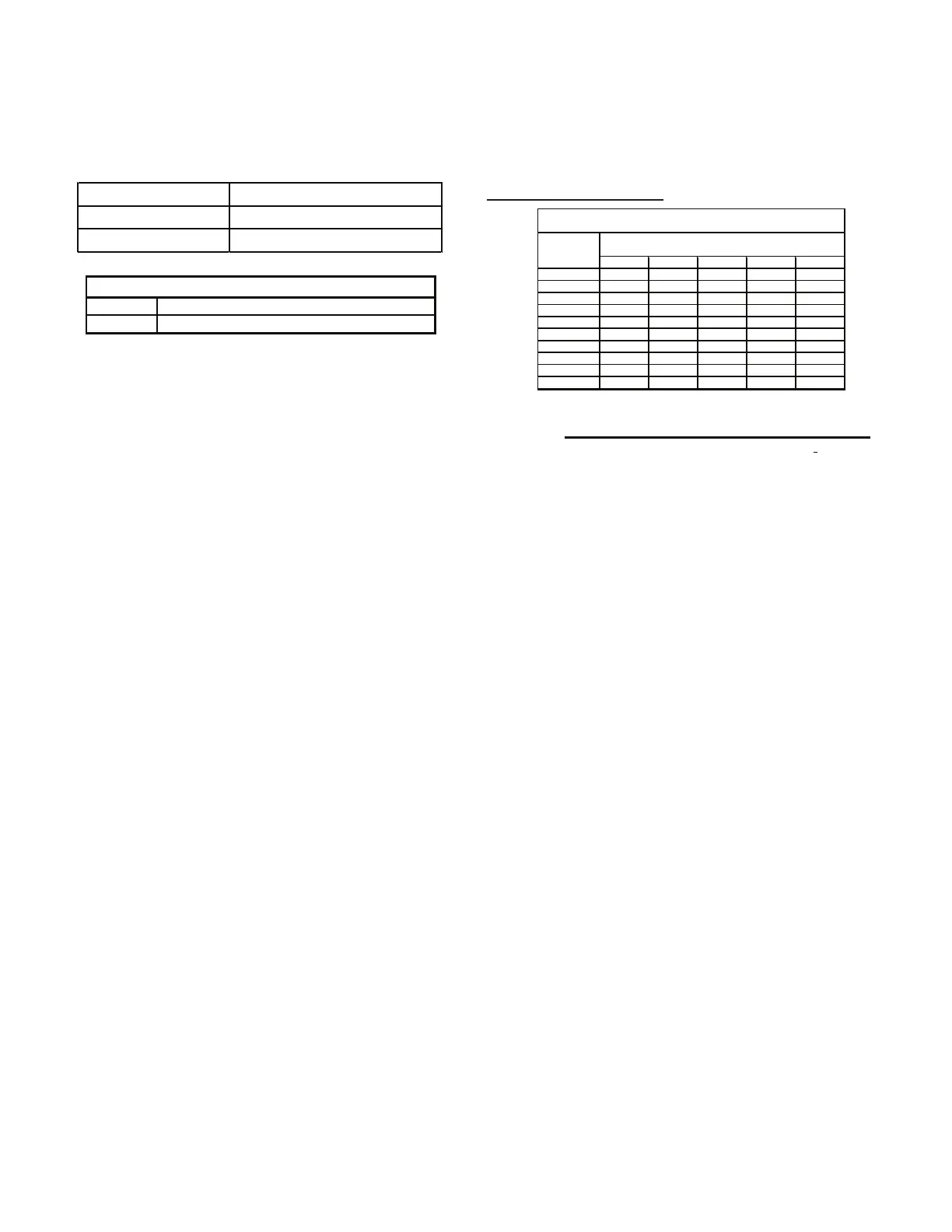

LP Conversion Kit Model

LPM-07 Single Stage Heating Models

LPM-08 Two-Stage Heating Models

Inlet Gas Pressure

Natural Min. 5.0" W.C., Max. 10.0" W.C.

Propane

Min. 11.0" W.C., Max. 13.0" W.C.

Inlet Gas Pressure must be within the minimum and maxi-

mum value shown in table above.

The minimum supply pressure should not vary from that

shown in the table above because this could prevent the

unit from having dependable ignition. In addition, gas input

to the burners must not exceed the rated input shown on

WKHUDWLQJSODWH2YHU¿ULQJRIWKHXQLWFRXOGUHVXOWLQSUHPD-

ture heat exchanger failure.

+එඏඐ$ඔගඑගඝඌඍ'ඍකඉගඍ86,ඖඛගඉඔඔඉගඑඖඛ2ඖඔඡ

,03257$17127(7ඐඍඏඉඛඍඔඍඋගකඑඋඝඖඑගඛඖඉගඝ-

කඉඔඔඡඌඍකඉගඍඟඑගඐඉඔගඑගඝඌඍ'ඖගඉගගඍඕගග

එඖඋකඍඉඛඍගඐඍඎඑකඑඖඏකඉගඍඊඡඋඐඉඖඏඑඖඏකඑඎඑඋඍඛක

එඖඋකඍඉඛඑඖඏගඐඍඕඉඖඑඎඔඌකඍඛඛඝකඍ7ඐඑඛඋඉඖඋඉඝඛඍ

කඋඕඊඝඛගඑඖඉඖඌඍඝඑඕඍඖගඎඉඑඔඝකඍ$ගඉඔඔ

ඉඔගඑගඝඌඍඛගඐඍඕඉඖඑඎඔඌකඍඛඛඝකඍඕඝඛගඊඍඟඑගඐඑඖ

එඖඋඐඍඛ:&ඎගඐඉගඔඑඛගඍඌඖගඐඍඖඉඕඍඔඉගඍ

ඎකගඐඍඎඝඍඔඝඛඍඌ$ගඉඔඔඉඔගඑගඝඌඍඛඉඖඌඟඑගඐඍඑගඐඍක

ඎඝඍඔගඐඍඉඑකගඍඕඍකඉගඝකඍකඑඛඍඕඝඛගඊඍඟඑගඐඑඖගඐඍ

කඉඖඏඍඔඑඛගඍඌඖගඐඍඝඖඑගඖඉඕඍඔඉගඍ

Refer to the Installation Manual provided with the LP kit for

conversion from natural gas to propane gas and for altitude

adjustments. NOTE: Up to 2,000 feet, no changes are

required; above 2,000 feet, please refer to the gas/electric

SDFNDJHXQLWVSHFL¿FDWLRQVKHHWVIRUUHTXLUHGNLWV8VH

HA03 for installations above 2000’.

Installation of the gas/electric unit at altitudes above 2000

IWPVKDOOEHPDGHLQDFFRUGDQFHZLWKWKHOLVWHG+LJK

Altitude Conversion Kit available for this gas/electric unit.

3එඑඖඏ

,03257$17127(7ඉඞඑඌඛඛඑඊඔඍඝඖඛඉගඑඛඎඉඋගකඡ

ඍකඉගඑඖකඍඝඑඕඍඖගඌඉඕඉඏඍඌඝඍගඝඖඌඍකඎඑකඑඖඏ

ඎඍඝඑඕඍඖගඌඖගඝඖඌඍකඛඑජඍගඐඍඖඉගඝකඉඔකඉඖඍ

ඏඉඛඑඑඖඏඎකඕගඐඍඕඍගඍකගඉඖඓගගඐඍඝඖඑග:ඐඍඖ

ඛඑජඑඖඏඉගකඝඖඓඔඑඖඍඑඖඋඔඝඌඍඉඔඔඉඔඑඉඖඋඍඛඖගඐඉග

ඔඑඖඍගඐඉගඋඝඔඌඊඍඍකඉගඍඌඛඑඕඝඔගඉඖඍඝඛඔඡ

The rating plate is stamped with the model number, type of

gas and gas input rating. Make sure the unit is equipped to

operate on the type of gas available. The gas line instal-

lation must comply with local codes, or in the absence of

local codes, with the latest edition of the National Fuel Gas

Code NFPA 54/ANSI Z223.1.

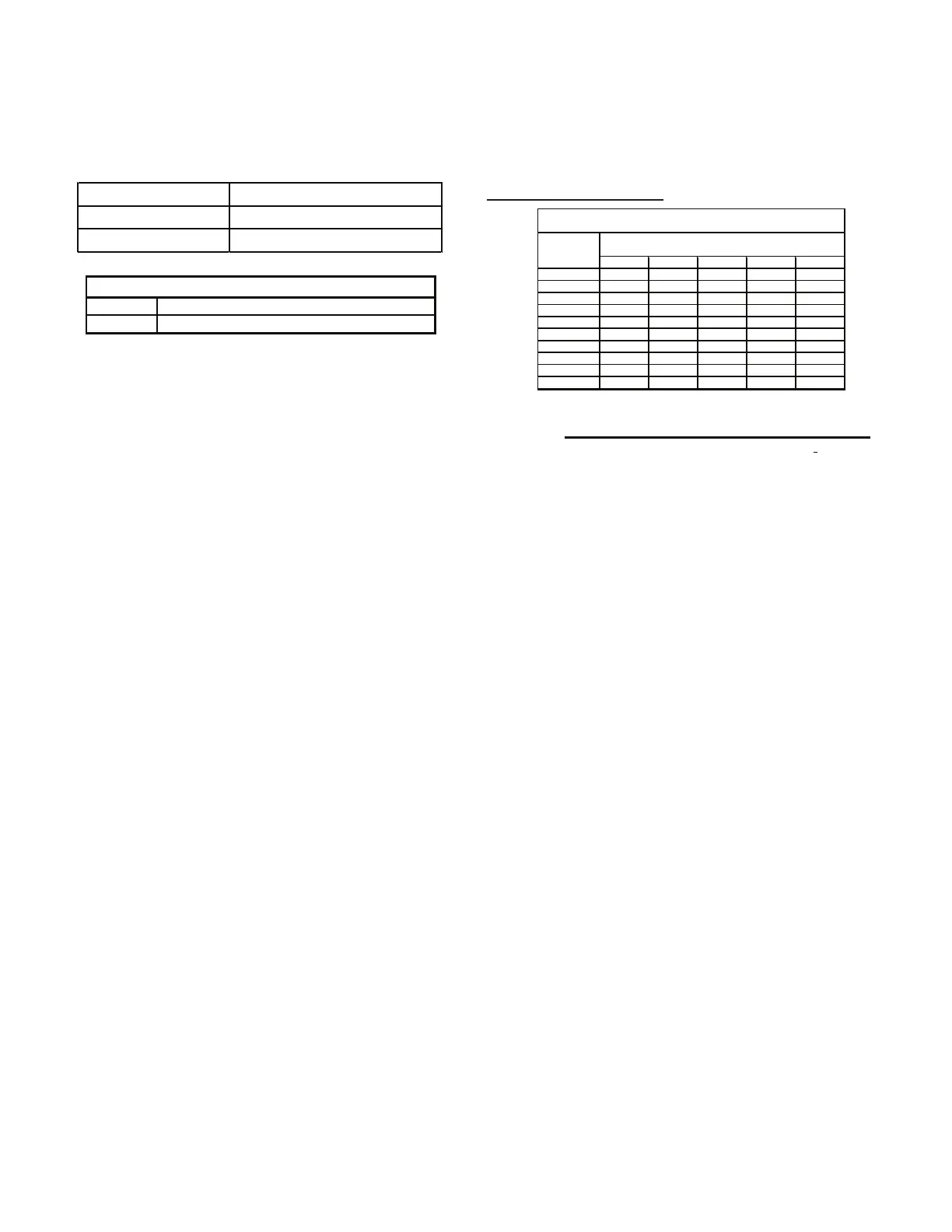

Natural Gas Connection

Pipe in Feet

1/2 3/4

1

1 1/4 1 1/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 980

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

3UHVVXUH 36,*RUOHVVDQG3UHVVXUH'URSRI:&%DVHG

RQ6SHFLILF*UDYLW\*DV

Natural Gas Capacity of Pipe

LQ&XELF)HHWRI*DV3HU+RXU&)+

1RPLQDO%ODFN3LSH6L]HLQFKHV

&DORULILF9DOXHRI*DV

+HDWLQJ9DOXHRI*DV%78&XELF )RRW

Refer to the Proper Piping Practice drawing for the general

OD\RXWDWWKHXQLW7KHIROORZLQJUXOHVDSSO\

1. 8VHEODFNLURQSLSHDQG¿WWLQJVIRUWKHVXSSO\SLSLQJ

7KHXVHRIDÀH[FRQQHFWRUDQGRUFRSSHUSLSLQJ

is permitted as long as it is in agreement with local

codes.

2. Use pipe joint compound on male threads only. Pipe

joint compound must be resistant to the action of the

fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can

enter the gas valve. The drip leg must be a minimum

of three inches long.

5. Use two pipe wrenches when making connection to

the gas valve to keep it from turning.

6. ,QVWDOODPDQXDOVKXWRႇYDOYHLQDFRQYHQLHQWORFDWLRQ

ZLWKLQVL[IHHWRIXQLWEHWZHHQWKHPHWHUDQGWKHXQLW

7. Tighten all joints securely.

8. The unit must be connected to the building piping by

RQHRIWKHIROORZLQJPHWKRGV

• 5LJLGPHWDOOLFSLSHDQG¿WWLQJV

• 6HPLULJLGPHWDOOLFWXELQJDQGPHWDOOLF¿WWLQJV

$OXPLQXPDOOR\WXELQJPXVWQRWEHXVHGLQH[WHULRU

ORFDWLRQV

• Listed gas appliance connectors used in accordance

with the terms of their listing that are completely in the

same room as the equipment

• In the prior two methods above the connector or

tubing must be protected from physical and thermal

damage. Aluminum alloy tubing and connectors must

be coated to protect against external corrosion when

in contact with masonry, plaster or insulation or are

VXEMHFWWRUHSHDWHGZHWWLQJVE\OLTXLGVZDWHUQRW

UDLQZDWHUGHWHUJHQWVRUVHZDJH

Loading...

Loading...