8

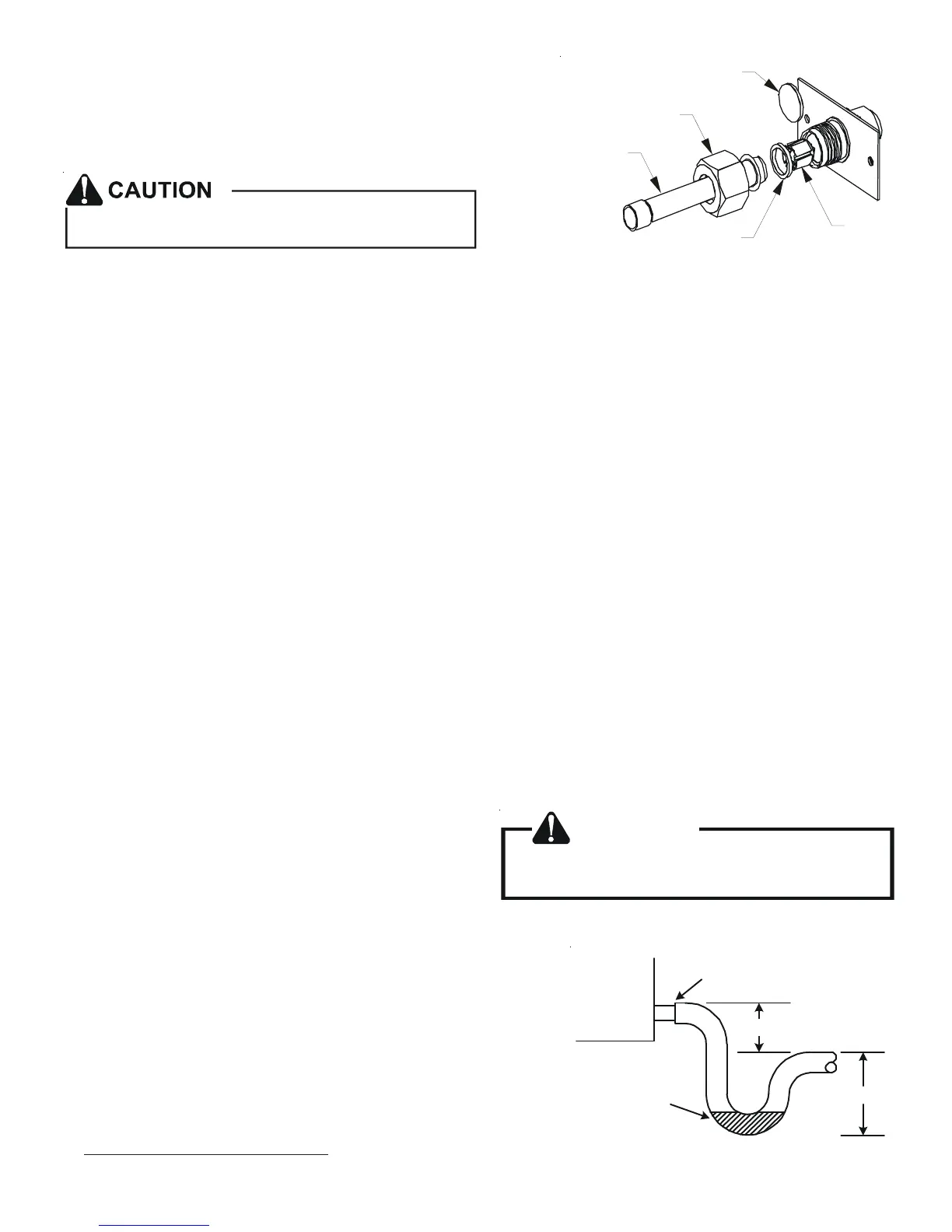

Excessive torque can cause orifices to stick. Use the

proper torque settings when tightening orifices.

WHITE

TEFLON SEAL

PISTON

TAILPIECE

13/16” NUT

PLASTIC or BRASS CAP

TAILPIECE JOINT

Figure 11

8. AFTER THE TAILPIECE HAS COOLED, confirm position of the white

Teflon

®

seal and hand tighten the 13/16 nut.

9. Torque the 13/16 nut to 7-25 ft-lbs. or tighten 1/6 turn.

7.5 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the bulb pre-

installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access panel.

2. Remove access valve fitting cap and depress the valve stem in access fitting to release pressure. No pressure indi-

cates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and slide grommet about 18" away from braze joint.

6. Insert suction line set into suction tube expansion and slide insulation and grommet about 18" away from braze joint.

7. Braze joints. Quench all brazed joints with water or a wet rag upon completion of brazing.

8 Condensate Drain Lines

The coil drain pan has a primary and a secondary drain with 3/4" NPT female connections. The connectors required are 3/

4" NPT male, either PVC or metal pipe, and should be hand tightened to a torque of no more than 37 in-lbs. to prevent

damage to the drain pan connection. An insertion depth of approximately 3/8” to 1/2” (3-5 turns) should be expected at

this torque.

1. Ensure drain pan hole is not obstructed.

2. To prevent potential sweating and dripping on to finished space, it may be necessary to insulate the condensate drain

line located inside the building. Use Armaflex

®

or similar material.

A secondary condensate drain connection has been provided for areas where the building codes require it. Pitch all drain

lines a minimum of 1/4" per foot to provide free drainage. Provide required support to the drain line to prevent bowing.

If the secondary drain line is required, run the line separately

from the primary drain and end it where condensate discharge

can be easily seen.

NOTE: Water coming from secondary line means the coil pri-

mary drain is plugged and needs immediate attention.

Insulate drain lines located inside the building or above a fin-

ished living space to prevent sweating. Install a condensate

trap to ensure proper drainage.

NOTE: When units are installed above ceilings, or in other locations

where damage from condensate overflow may occur, it is MANDATORY

to install a field fabricated auxiliary drain pan under the coil cabinet

enclosure.

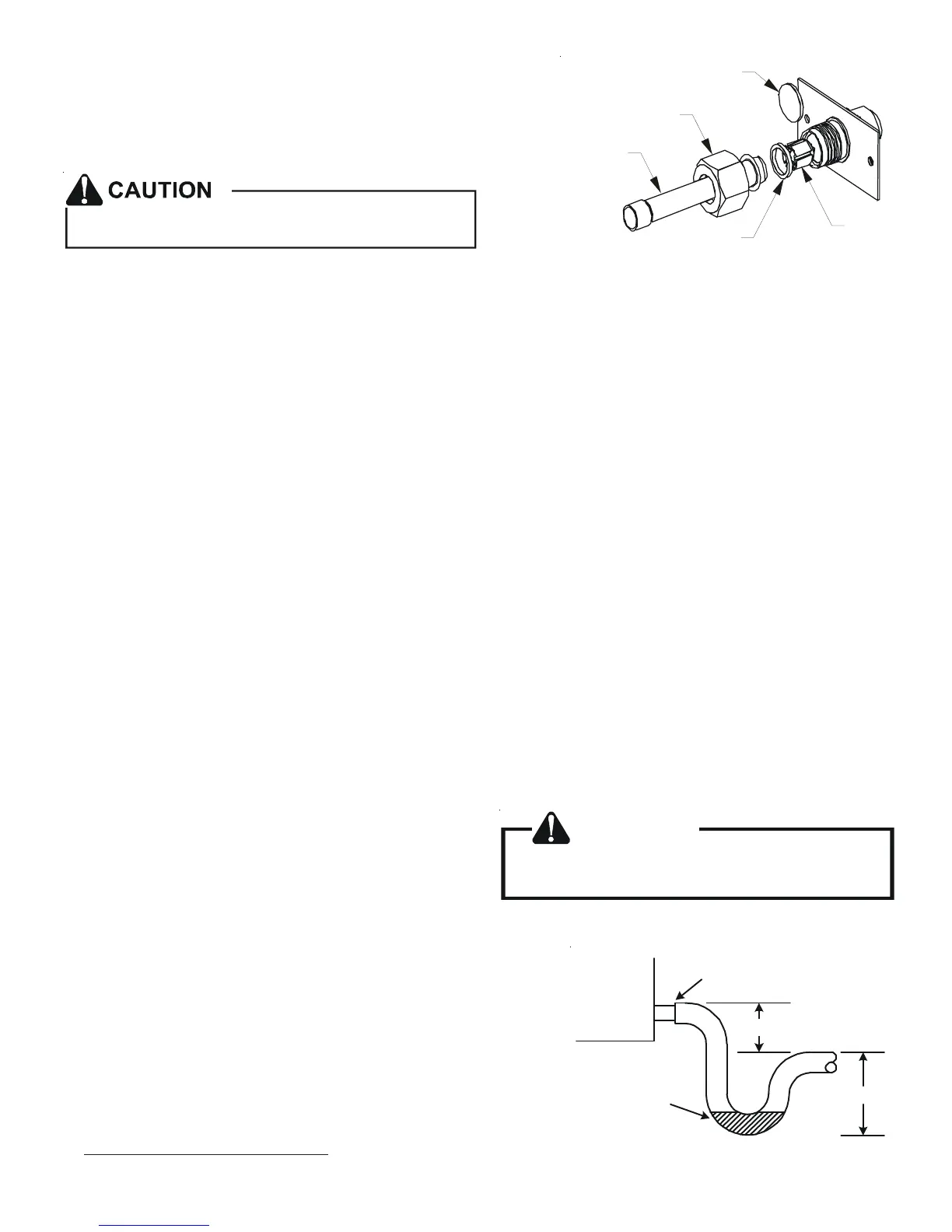

The installation must include a “P” style trap that is located as close as

is practical to the evaporator coil. See Figure 12 for details of a typical

condensate line “P” trap.

NOTE: Trapped lines are required by many local codes. In the absence

of any prevailing local codes, please refer to the requirements listed in

the Uniform Mechanical Building Code.

CAUTION

If secondary drain is not installed, the secondary

access must be plugged.

Air Handler

3" MIN.

POSITIVE LIQUID

SEAL REQUIRED

AT TRAP

Drain

Connection

2" MIN.

Figure 12

Loading...

Loading...