7

7 Refrigerant Lines

NOTE: Refrigerant tubing must be routed to allow adequate

access for servicing and maintenance of the unit.

Do not install the air handler in a location that violates

the instructions provided with the condenser. If the unit

is located in an unconditioned area with high ambient

temperature and/or high humidity, the air handler may

be subject to nuisance sweating of the casing. On these

installations, a wrap of 2" fiberglass insulation with a vapor

barrier is recommended.

7.1 Tubing Size

For the correct tubing size, follow the specification

for the condenser/heat pump.

7.2 Tubing Preparation

All cut ends are to be round, burr free, and clean.

Failure to follow this practice increases the chances

for refrigerant leaks. The suction line is spun closed

and requires tubing cutters to remove the closed end.

NOTE: To prevent possible damage to the tubing joints, do not handle coil assembly with manifold or flowrator tubes.

Always use clean gloves when handling coil assemblies.

7.3 Special Instructions

Units without a factory installed TXV come equipped with a flowrator piston for refrigerant expansion. For most

installations with matching applications, no change to the flowrator piston is required. However, in mix-matched

applications, a flowrator piston change may be required. See the piston kit chart (provided in the literature packet)

or consult your local distributor for details regarding mix-matched flowrator piston sizing. If the mix-match appli-

cation requires a different flowrator piston size, change the flowrator piston in the flowrator body on the indoor

coil before installing the coil and use the procedure in section 8.4.

NOTE: The use of a heat shield is strongly recommended when brazing to avoid burning the serial plate or the finish

of the unit. Heat trap or wet rags must be used to protect heat sensitive components such as service valves and TXV

valves sensing bulb.

7.4 Tubing Connections for Flowrator Model

1. Loosen the 13/16 nut 1 TURN ONLY to allow high pressure tracer

gas to escape. No gas indicates a possible leak.

2. After the gas has been expelled, remove the nut and discard the

black or brass cap plastic seal.

3. Remove the flowrator piston to verify it is the correct size for

the outdoor unit being installed and then replace the piston

(changing size, if needed). See piston kit chart in the literature

kit for appropriate piston size.

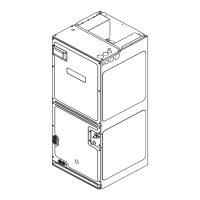

4. Remove the spin closure on the suction line using a tube cutter

and deburr the tube.

5. Insert the suction line into the connection, slide the insulation and the rubber grommet at least 18" away from the

braze joint.

6. Remove the tailpiece clamped to the exterior of the cabinet or in the literature kit packet and slide the 13/16 nut

into place.

7. Braze tailpiece to the line set liquid tube and braze suction line connection. Quench all brazed joints with a damp

rag upon completion of brazing. Do not allow water to enter the inside of the tubing.

This product is factory-shipped with R410A and dry

nitrogen mixture gas under pressure. Use appropriate

service tools and follow these instructions to prevent

injury.

A quenching cloth is strongly recommended to prevent

scorching or marring of the equipment finish when

brazing close to the painted surfaces. Use brazing

alloy of 5% minimum silver content.

Applying too much heat to any tube can melt the tube. Torch

heat required to braze tubes of various sizes must be

proportional to the size of the tube. Service personnel must

use the appropriate heat level for the size of the tube being

brazed.

CAUTION

RUBBER

GROMMET

SUCTION LINE

WITH SPIN CLOSURE

SUCTION SPUN END AND GROMMET

Figure 10

Loading...

Loading...