8

STEP 2. CONNECT HEAT PUMP UNIT TO SYSTEM

OPEN THE LIQUID VALVE FIRST! I

F

THE

GAS

SERVICE

VALVE

IS

OPENED

FIRST

,

OIL

FROM

THE

COMPRESSOR

MAY

BE

DRAWN

INTO

THE

INDOOR

COIL

OR

TXV

RESTRICTING

REFRIGERANT

FLOW

AND

AFFECTING

OPERATION

OF

THE

SYSTEM

.

POSSIBLE REFRIGERANT LEAK!

T

O

AVOID

A

POSSIBLE

REFRIGERANT

LEAK

,

OPEN

THE

SERVICE

VALVES

UNTIL

THE

TOP

OF

THE

STEM

IS

1/8”

FROM

THE

RETAINER

.

CAUTION

E

NSURE

VALVES

ARE

OPEN

AND

ADDITIONAL

CHARGE

IS

ADDED

PER

CHART

BEFORE

APPLYING

POWER

.

CAUTION

When opening valves with retainers, open each valve only until

the top of the stem is 1/8” from the retainer. To avoid loss of

refrigerant, DO NOT apply pressure to the retainer. When open-

ing valves without a retainer, remove service valve cap and in-

sert a hex wrench into the valve stem and back out the stem by

turning the hex wrench counterclockwise. Open the valve until it

contacts the rolled lip of the valve body.

NOTE: Units may utilize ball valves or front seating valves. These

are not back-seating valves. It is not necessary to force the stem

tightly against the rolled lip.

After the refrigerant charge has bled into the system, open the

liquid service valve. The service valve cap is the secondary seal

for the valves and must be properly tightened to prevent leaks.

Make sure cap is clean and apply refrigerant oil to threads and

sealing surface on inside of cap. Tighten cap finger-tight and then

tighten additional 1/6 of a turn to properly seat the sealing sur-

faces.

Do not introduce liquid refrigerant from the cylinder into the

crankcase of the compressor as this may damage the compres-

sor.

Break vacuum by fully opening liquid and gas base valve.

ATTENTION INSTALLER - IMPORTANT NOTICE!

Please read carefully before installing this unit.

• For AVZC20, do not install the 24 Volt Transformer that is included with the CTK04 Thermostat in the Heat

Pump Unit; it is not needed.

• Do not attach any wires to the R & C Terminals on the Heat Pump Unit, as they are not needed for inverter unit

setup.

•DATA LINE TERMINALS #1 AND #2 ARE POLARITY SENSITIVE. ONLY THE DATA LINES, 1 AND 2, ARE REQUIRED BETWEEN THE INDOOR AND

OUTDOOR

UNITS.

•DATA LINE TERMINAL #1 FROM OUTDOOR UNIT MUST CONNECT TO TERMINAL #1 ON INDOOR UNIT AND DATA LINE TERMINAL #2 FROM

OUTDOOR

UNIT MUST CONNECT TO TERMINAL #2 ON INDOOR UNIT. VERIFY WIRES ARE NOT REVERSED.

•IT IS STRONGLY RECOMMENDED TO USE WIRE NUTS AT THE INDOOR UNIT WHEN CONNECTING MULTIPLE DATA LINES OR LOW VOLTAGE WIRES

TOGETHER

. IT IS NOT RECOMMENDED TO USE THE TERMINAL BLOCK TO CONNECT TWO OR MORE WIRES.

• Calculate the Liquid Line Set length and weigh in 0.6 ounces per foot of R410A refrigerant for any length over

15 feet.

Or

• Charge by Sub-cooling.

Sub-cooling should be between 7° and 9°F. Allow 10 minutes of running in Charge Mode between each

amount of refrigerant added.

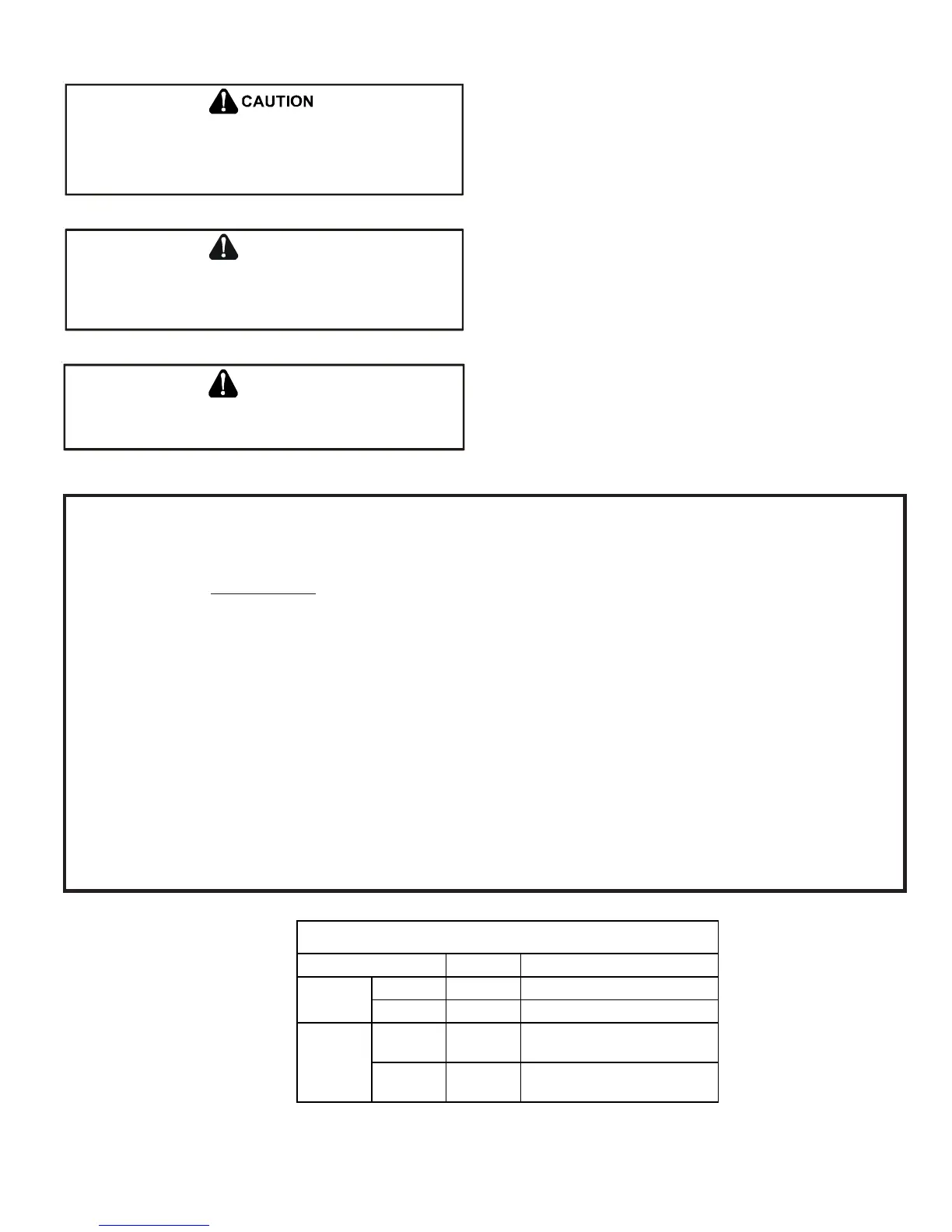

Setting Purpose

1 ON CT Communication Enabled

2 ON CT Communication Enabled

1ON

Cooling Emergency Mode

for Future Use *

2ON

Cooling Emergency Mode

for Future Use *

OD DS1

OD DS2

Switch #

DIPSWITCH FACTORY DEFAULT SETTINGS

* OD DS2 switch 1 and 2 both must be turned on

during normal operation mode

Loading...

Loading...