51 Rev. 2

SYSTEM OPERATION

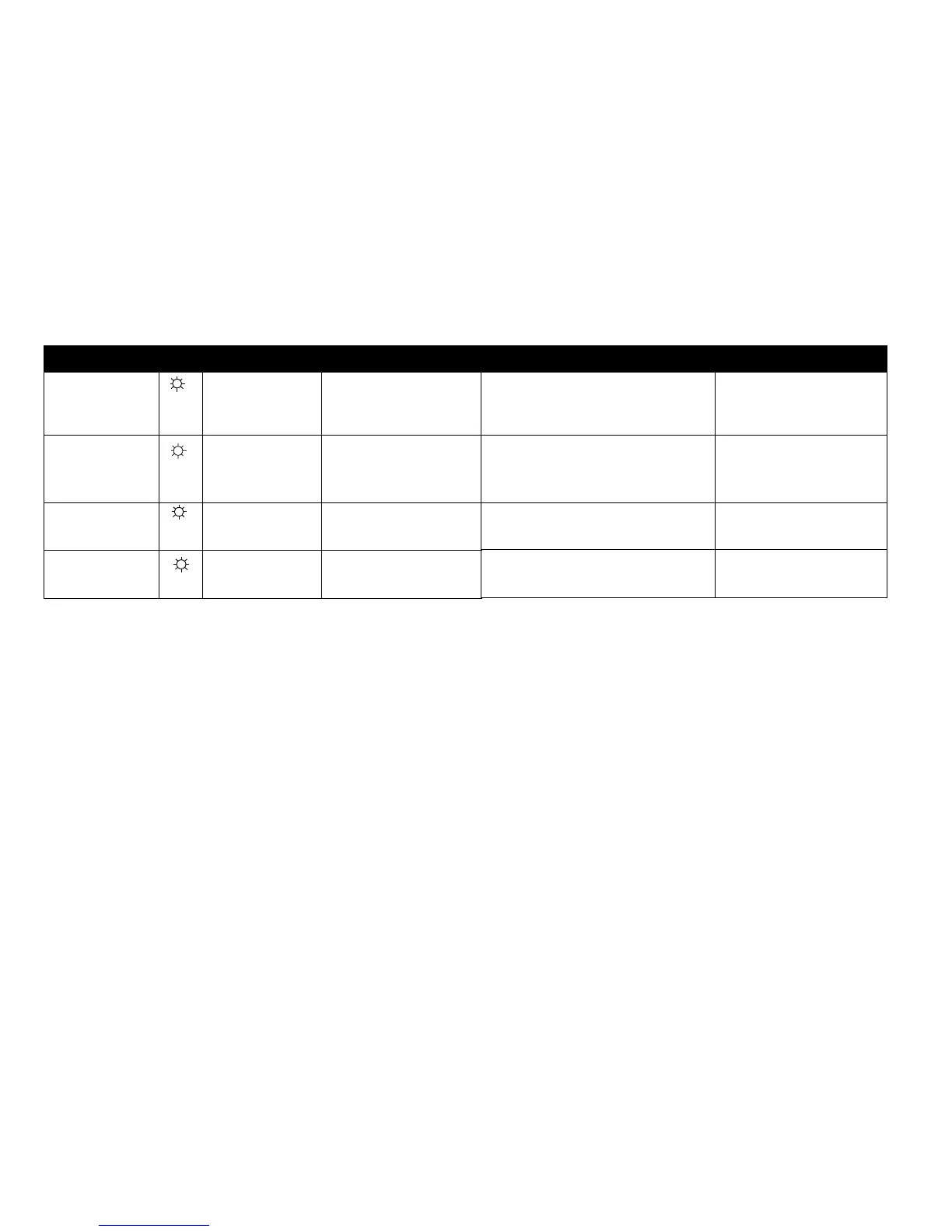

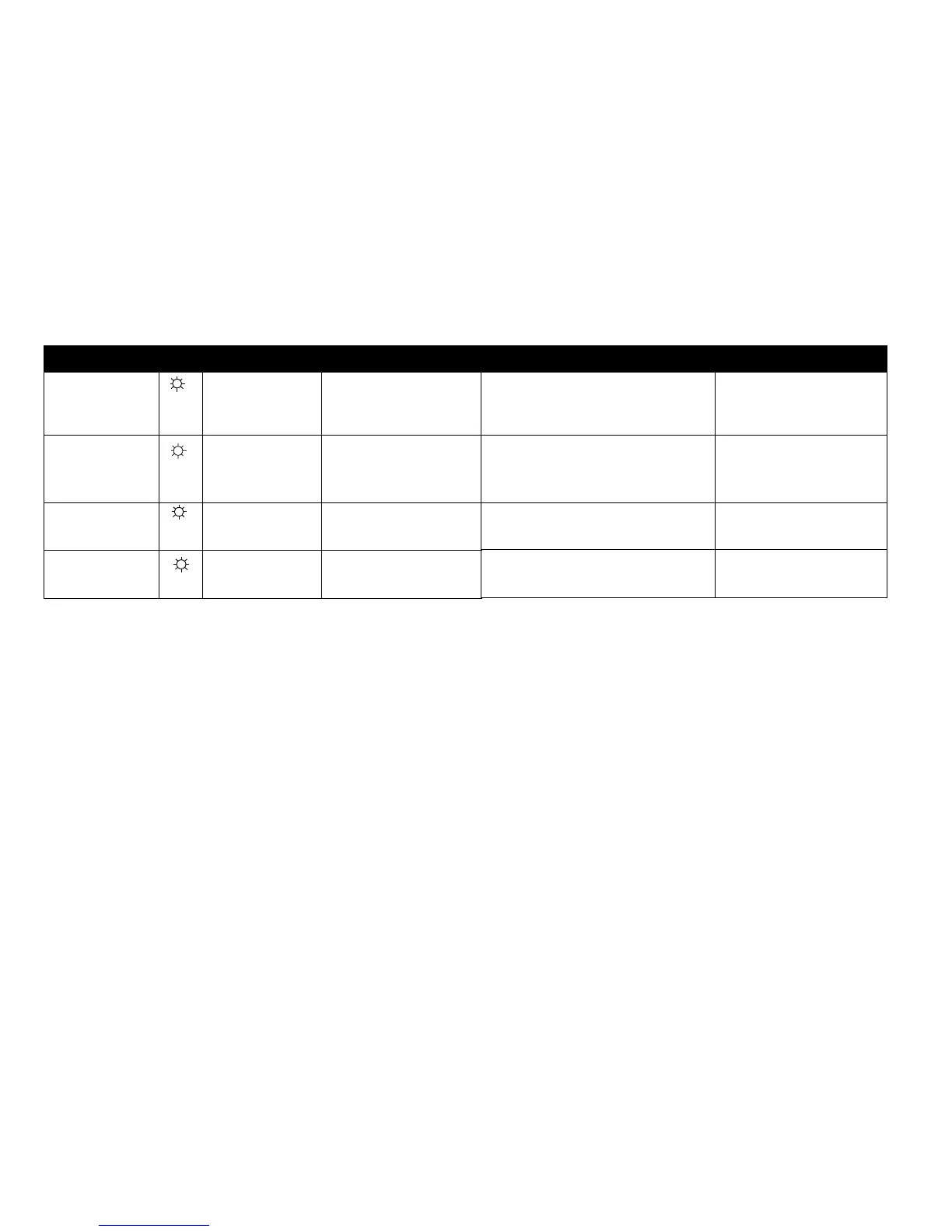

TROUBLESHOOTING CHART FOR MODELS USING HEATCRAFT HSI-2 IGNITION CONTROL

Sheet 2 of 2

Corrective Action

Cautions and

Notes

- Correct short at flame sensor or in flame sensor wiring. - Turn power OFF prior to repair.

- Sand flame sensor if coated/oxidized. Inspect for proper sensor alignment.

- Check inlet air piping for blockage, proper length, elbows, and termination.

- Check for proper gas pressures.

- Turn power OFF prior to repair.

- Sand flame sensor with emery cloth.

- See "Flue and Combustion Air Pipe" section for piping

details.

- See rating plate for proper gas pressures.

- Turn power OFF prior to repair.

- See "Flue and Combustion Air Pipe" section for piping

details.

- Replace pressure switch with proper replacement part.

- Check filters and ductwork. For blockage . Clean filters or remove obstruction.

- Check for proper circulation blower speed and performance. Correct speed or replace

blower if necessary.

- Check and correct wiring.

- Turn power OFF prior to repair.

- See Specification Sheet for allowable rise range and proper

circulator blower speed.

- Check and correct pressure switch hose.

- Check flue and/or inlet air piping for blockage, proper length, elbows

and termination. Check drain system.

- Verify proper pressure switch set point and contact motion.

- Check and correct wiring.

Symptoms of Abnormal

Operation

Associated

LED Code

(See Note 2)

Fault Description(s) Possible Causes

- Induced draft and circulator blower run

continuously with no further

furnace operation.

and

- Integrated control module diagnostic

LED is flashing continuously.

Continuous

Flashing

- Flame has been sensed with no call

for heat.

- Short to ground in flame sense circuit.

7 Flashes

- Normal furnace operation.

but

- Integrated control module diagnostic

LED is flashing seven flashes.

- Flame sense micro-amp signal is low.

- Flame sensor is coated/oxidized.

- Flame sensor incorrectly positioned in burner flame.

- Lazy burner flame due to improper gas pressure, or

combustion air.

- Circulator blower running continuously

with

no further furnace operation

and

- Integrated control module diagnostic

LED is flashing nine flashes.

9 Flashes

- Furnace is not operating

and

- Integrated control module diagnostic

LED is flashing eight flashes.

8 Flashes

- Pressure switch circuit has opened five

times during a single call for heat.

See note 3.

- Pressure switch hose blocked, pinched, or

misconnected.

- Blocked flue and/or inlet air pipe, blocked drain

system, or weak induced draft blower.

- Incorrect pressure switch set point or

malfunctioning switch contacts.

- Loose or misconnected wiring.

- Limit circuit (primary or auxiliary) has

opened five times during a single call

for heat. See note 1.

- Insufficient conditioned air over the heat exchanger.

Cause may be blocked filters, restrictive

ductwork, improper circulator blower speed, or

failed circulator blower.

- Loose or misconnected wiring.

C

White Rodgers

Control Only

Loading...

Loading...