4.2 Op er a tion

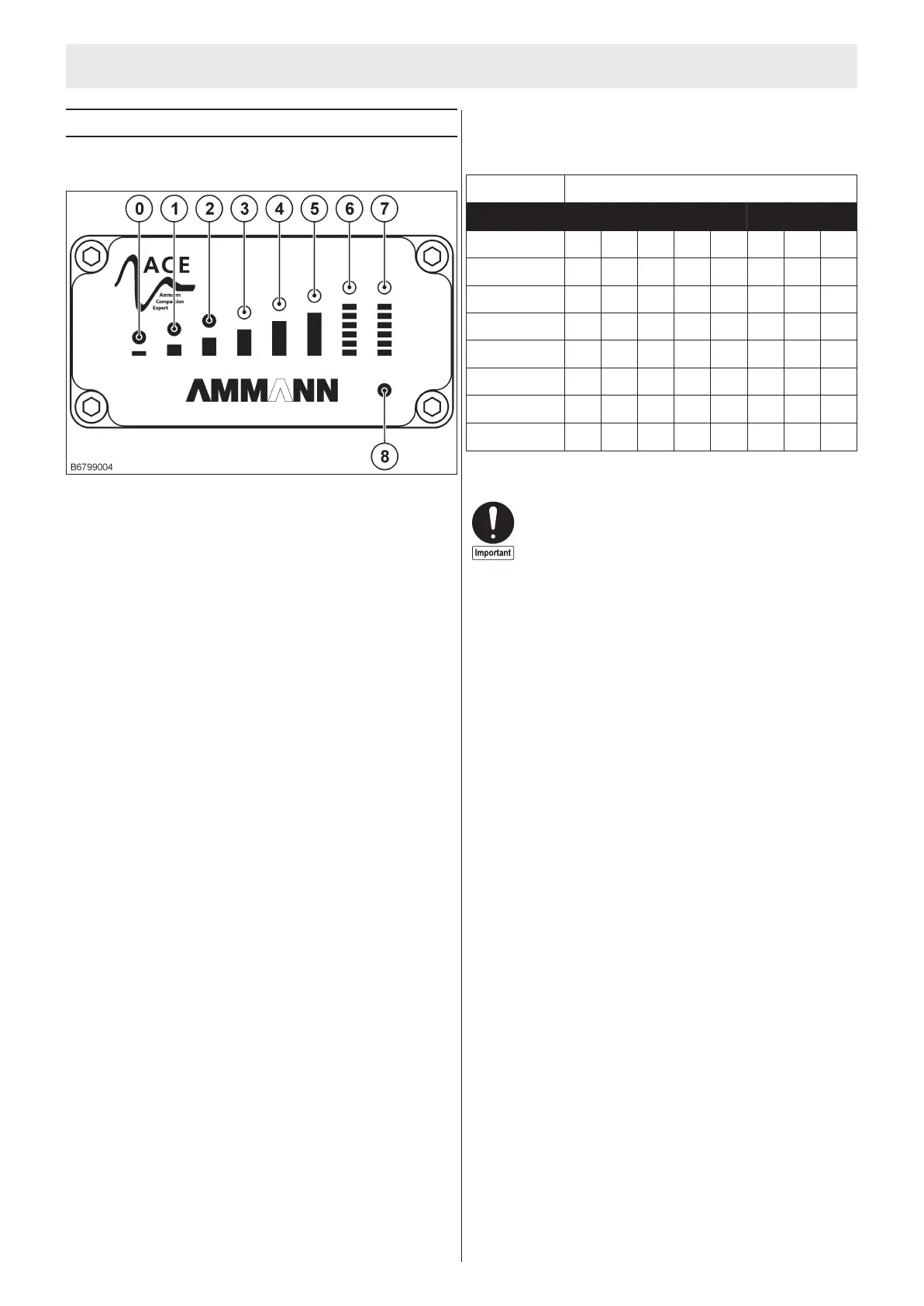

The var i ous op er at ing sta tuses are shown on the con trol panel

as fol lows:

•

The sys tem starts au to mat i cally when the ma chine is started.

Next, the sys tem initializes:

- The sta tus LED (8) blinks; the LEDs (0-7) light up in a row

from 0 to 7 and then go back off.

•

Af ter suc cess ful ini tial iza tion, the sta tus LED (8) glows. The

sys tem is now ready to op er ate.

•

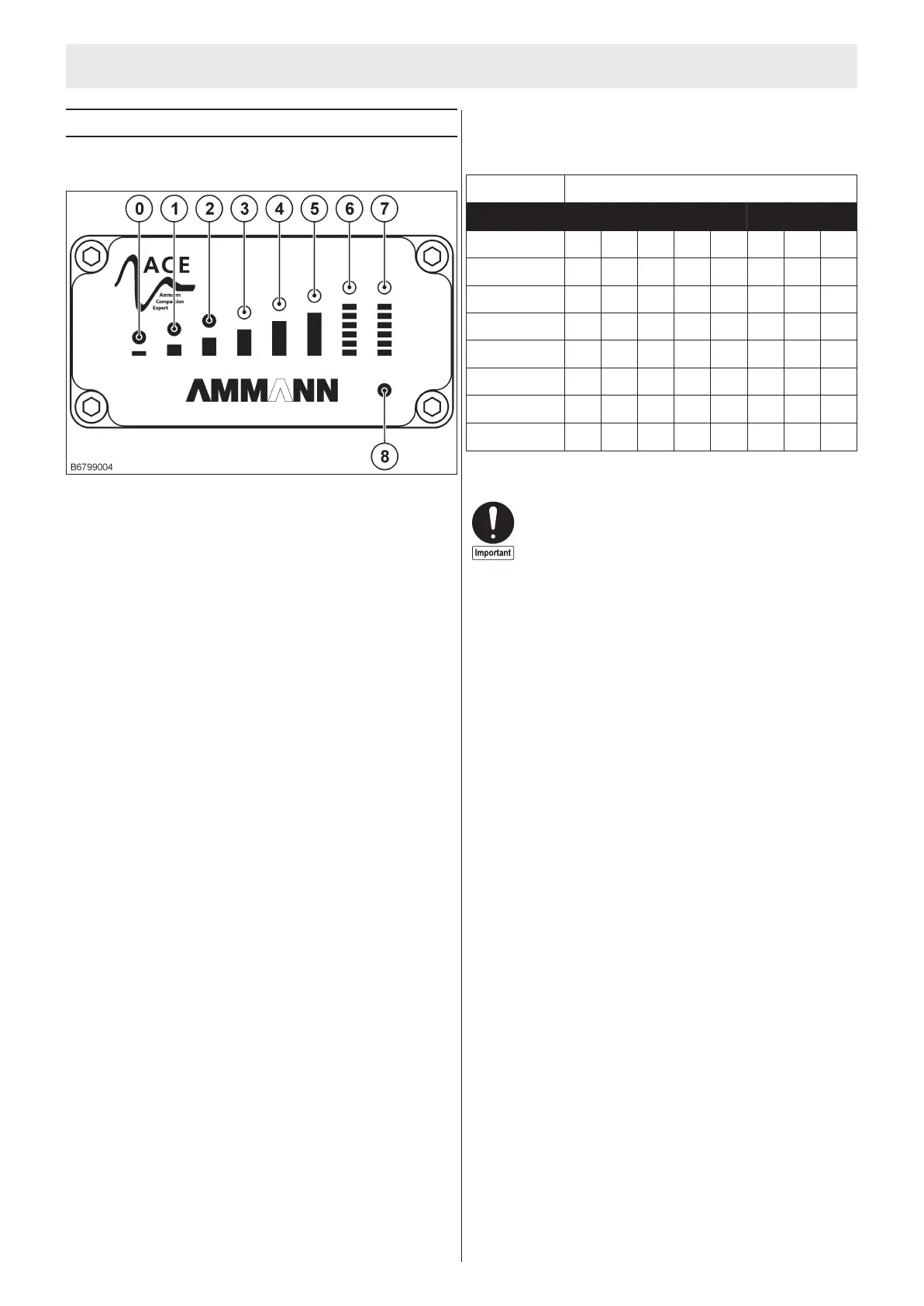

The rel a tive com pres sion value is shown by the LEDs as fol -

lows. The num ber of glow ing LEDs sym bol i cally rep re sents

the in creas ing soil com pres sion.

LED

VG

0 1 2 3 4 5 6 7

0 – 19 %

l

20 – 40 %

l l

41 – 60 %

l l l

61 – 80 %

l l l l

81 – 100 %

l l l l l

101 – 120 %

l l l l l l

121 – 140 %

l l l l l l l

141 – 150 %

l l l l l l l l

l – red

VG – De gree of com pres sion

•

If the sta tus LED glows, and the 0 LED blinks, the vi bra tion fre -

quency is to high or too low. No mea sure ment value can be

cal cu lated.

•

If the 0 LED glows, and the sta tus LED gives off a blink sig nal,

the mea sur ing sys tem is mal func tion ing. In this case, con tact

Ammann ser vice.

1)

Op tio nal equip ment

LM22020000-2 HbmG gnu thci dreV nna mmA 8102/20

Cor rect mea sure ment val ues can only be achieved by

driv ing for ward and back wards at max i mum speed.

4. ACEe con sys tem

51

Loading...

Loading...