7. Removal of pumps, cento clutch

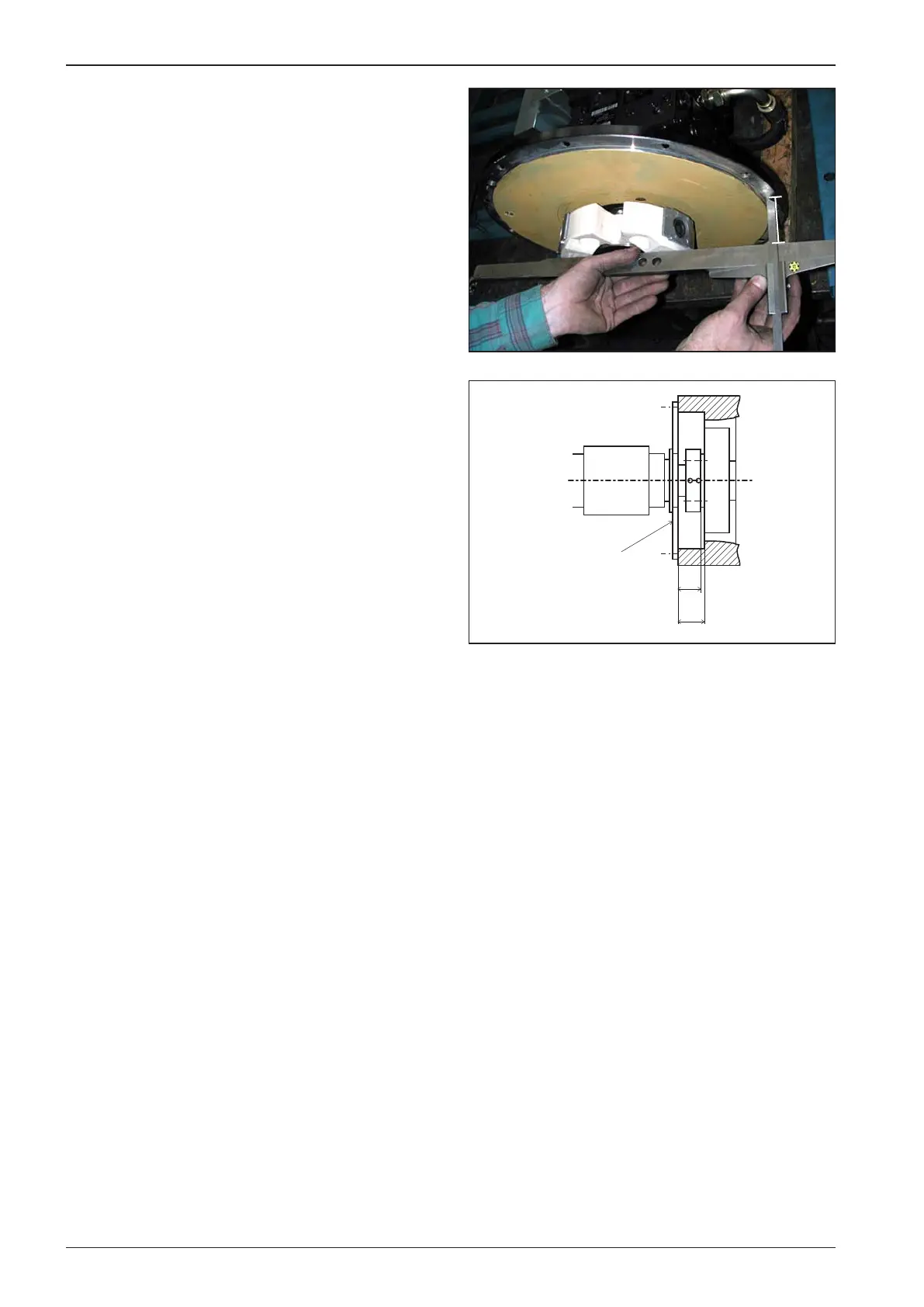

Measure distance „b“ from the elastic element face to the seat-

ing area of ange (106-12).

Dierence in the distances a - b = 1 ÷ 3 mm.

Colored (e. g. blue color) material is deposited on the thread

of the supplied countersunk hexagonal screws. Such material

includes a lm of adhesive and prevents its releasing. The time

of hardening of such adhesive material after screwing the bolts

is 4 ÷ 5 hours at the ambient temperature of 20 °C. The opera-

tion of the machine should not start before this time period

has elapsed. Full hardening is nished after 24 hours. At higher

temperatures the hardening can be faster, e. g. 15 minutes at

70 °C (heating performed by a hot air fan). Temperature stability

of the bolts is between -80 ÷ +90 °C (-112÷ +194 °F) and they

can be used three times at maximum. The adhesive material is

sometimes wiped o and it is deposited between the head of

the bolt and the segment. This is not a defect, rather advantage

- both areas will adhere to each other better. If original supplied

bolts are not available, both the bored thread and bolt must be

carefully degreased and a layer of Loctite or Omnit should be

applied to them.

Spring washers are not allowed!

The tandem of hydraulic generators including the connection of

hydraulic hoses and electrical wiring should be installed using

a crane in the opposite way.

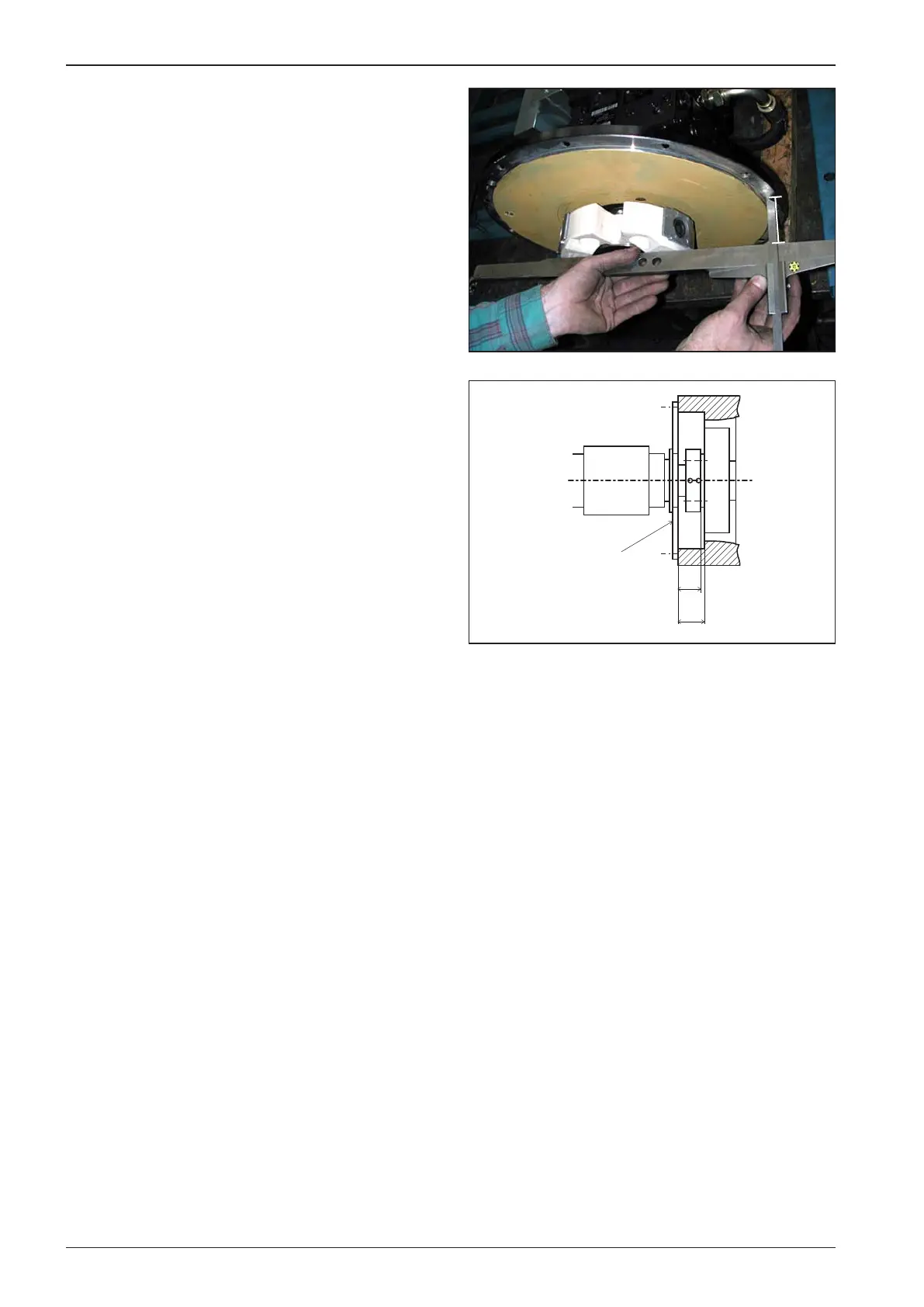

Tightening torque

T 1 bolt 155 ÷ 165 Nm

T 2 bolt 120 Nm

Loading...

Loading...