MOUNTIN

G

MACHINE

Place the machine on the assembled tool stand. The

front

side

of

the

machine

(the

side

with

the

"

AMT"

nameplate)

should

be facing the same side as the

switch

of

the

tool

stand.

On

the

end

of

the

top

panel

(the

end

closest

to

the switch), fasten the machine

down

with

two

mounting

bolts

(Nos. 106)

and

washer

(No. 107)

through

the

inner

slots.

Through

the

middle

slot

on

the

other

e

nd

, fasten

with

the

remaining

mounti

ng

bolt

and washer.

BELT

AND

PUllEY

The

machine

pulley

(2·5f8 dia. x

518

bore)

is

already

assembled

on

the

cutterhead

shaft.

If

the

shaft

on

your

mol

or is 1'2 dia

.,

use motor pulley sleeve (No.

70)

for

adequate

fitling

. Place

molor

pulley

key (No.

69)

in

slot

on

motor

pulley

" 0 " (No. 71)

and

slide

on

motor

shaft

. Put

socket

set

screw

(No.

72)

in

motor

pulley. but leave

loose

till

after

pulleys

are atigned

properly.

Assemble

V-belt "C" (1/2 x

36)

(No.

68)

to

the

machine

pulley and

motor

pulley. To align the

motor

pulley

to the

machine

pulley, use a straight

edge.

If necessary

both

pulleys

can be moved in

or

out

on the

shafts

or

the

complete

molar

mount

assembly

can be moved in

or

out

to bring the putleys

into

alignment.

If

necessary, loosen the fasteners

that

hold

the

motor

to

the

motor

mount

and move

the

motor

up

or

down

until

correct

belt tension is

obtained. Correct

belt

tension

is

obtained

when

there is

approximately

1"

deflection

in the center

span

of

the

belt

using

light

finger

pressure. See

"O

PERATING SPEED REQUIREMENTS" for

co

rrect

pulley

selection.

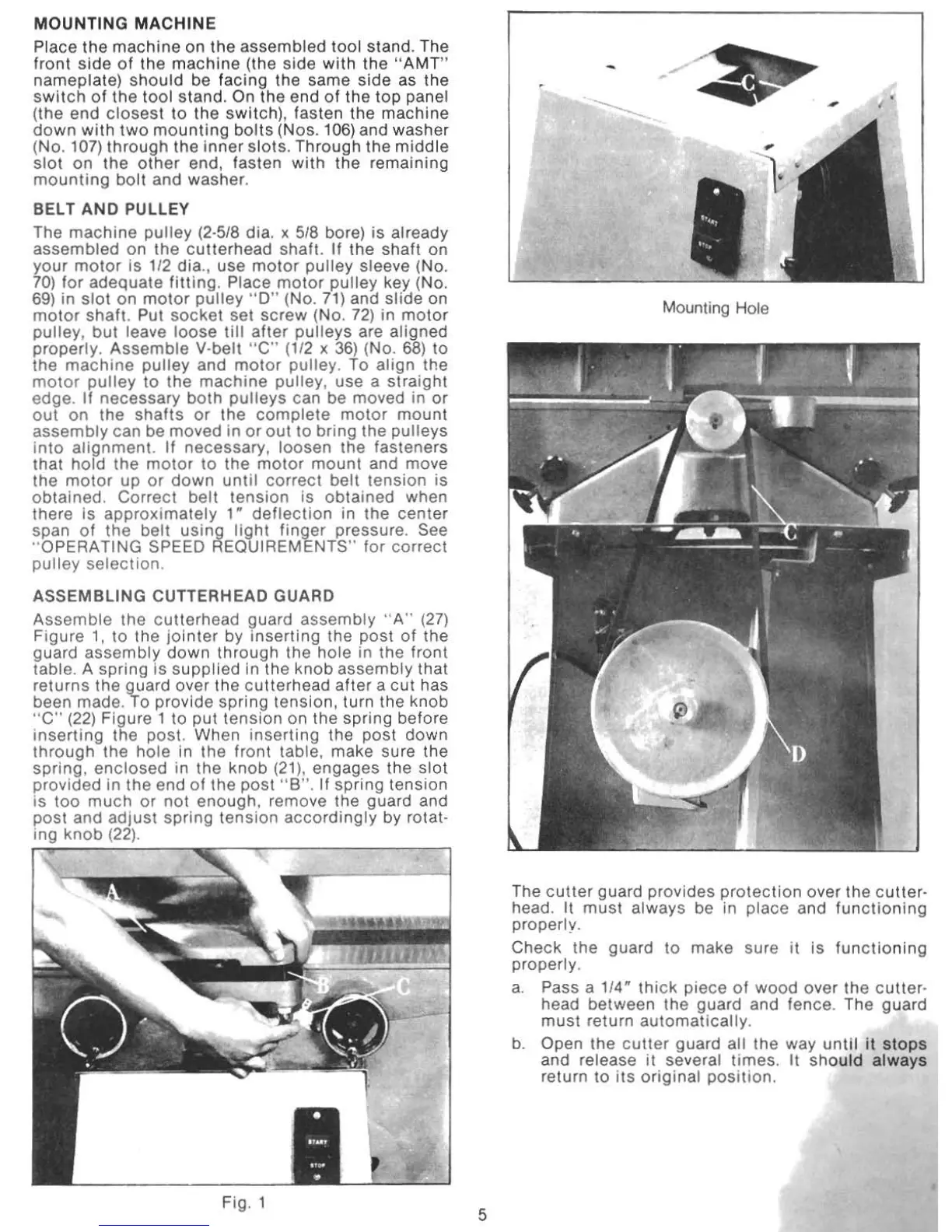

ASSEMBLING

CUTTERHEAD GUARD

Assemble

the cuUerhead l;Iuard

assembly

" A"

(27)

Figure 1, to the

jointer

by Inserting the post

of

the

guard

assembly

down

through

the hole in the front

tabl

e.

A spring is

supplied

in the knob

assembly

that

returns the guard over the c

utt

erhead

after

a cut has

been made.

To

provide

spring

tension, turn the knob

"C"

(22)

Figure 1 to put

tension

on the spring before

inserting

the post. When

inserting

the post down

through

the

hole

in the front table, make sure the

spring,

enclosed

in the knob (21), engages the

slot

provided in

the

end

of

the post

"8".

If

spring

tension

is too

much

or

not

enough, remove the guard and

post and

adjust

spring

tension

accordingly

by rotat-

ing

knob

(22).

Fig. 1

5

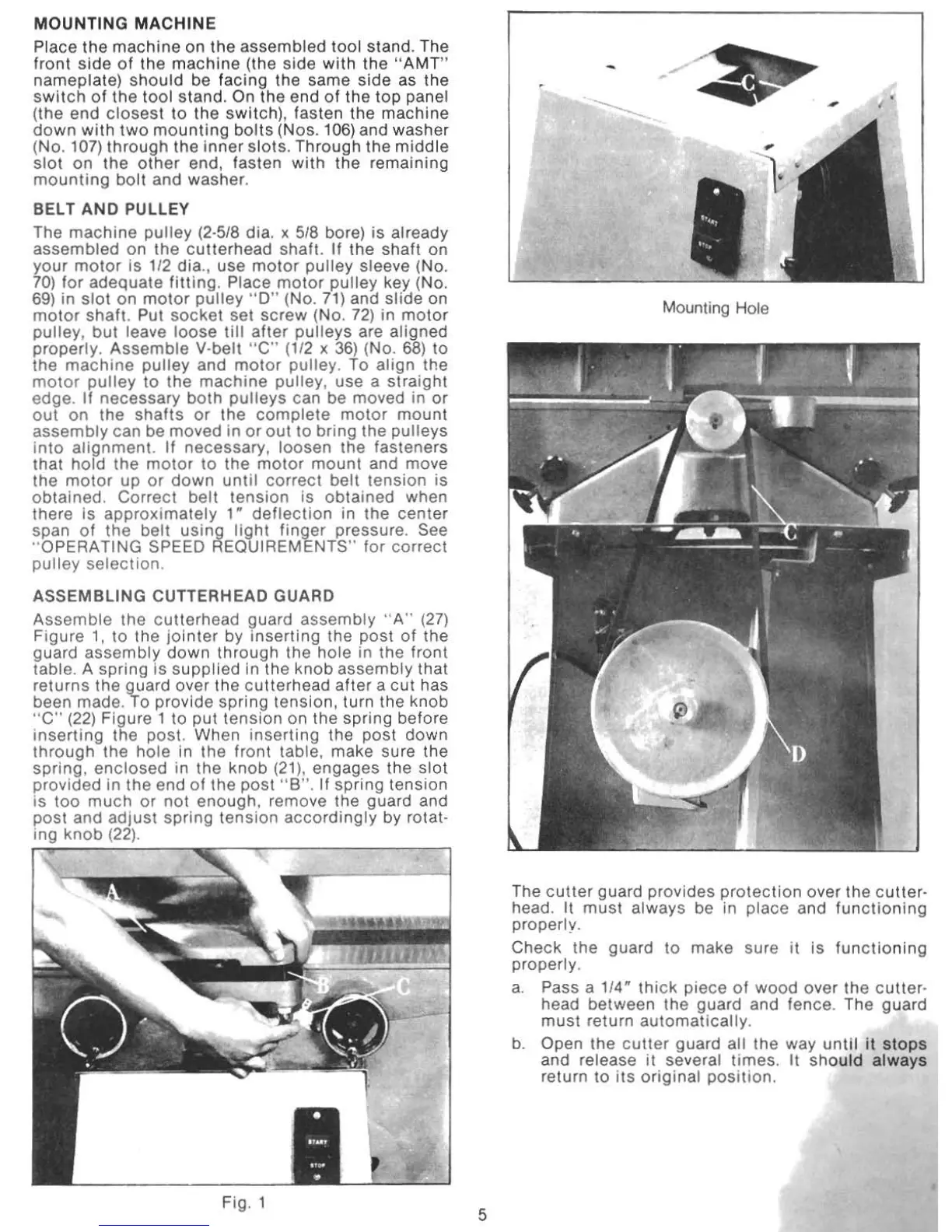

Mounting Hole

The

cutter

guard provides

protection

over the cutter-

head. It

must

always be in place and

functioning

properly.

Check the guard to make sure

it

is

functioning

properly.

a.

Pass a 1/4"

thick

piece

of

wood over the cutter-

head between the guard and fence. The guard

must

return automaticalty.

b.

Open the

cutter

guard all the way

until

it

stops

and release it several times. It should

always

re

turn to

its

original

position,

Loading...

Loading...